Ceramic-based ternary composite material with weak negative dielectric properties and preparation method thereof

A composite material and ceramic-based technology, which is applied in the field of ceramic-based ternary composite materials and its preparation, can solve the problems that the performance needs to be further improved and reduced, and achieve the effect of good technology transformation prospect and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

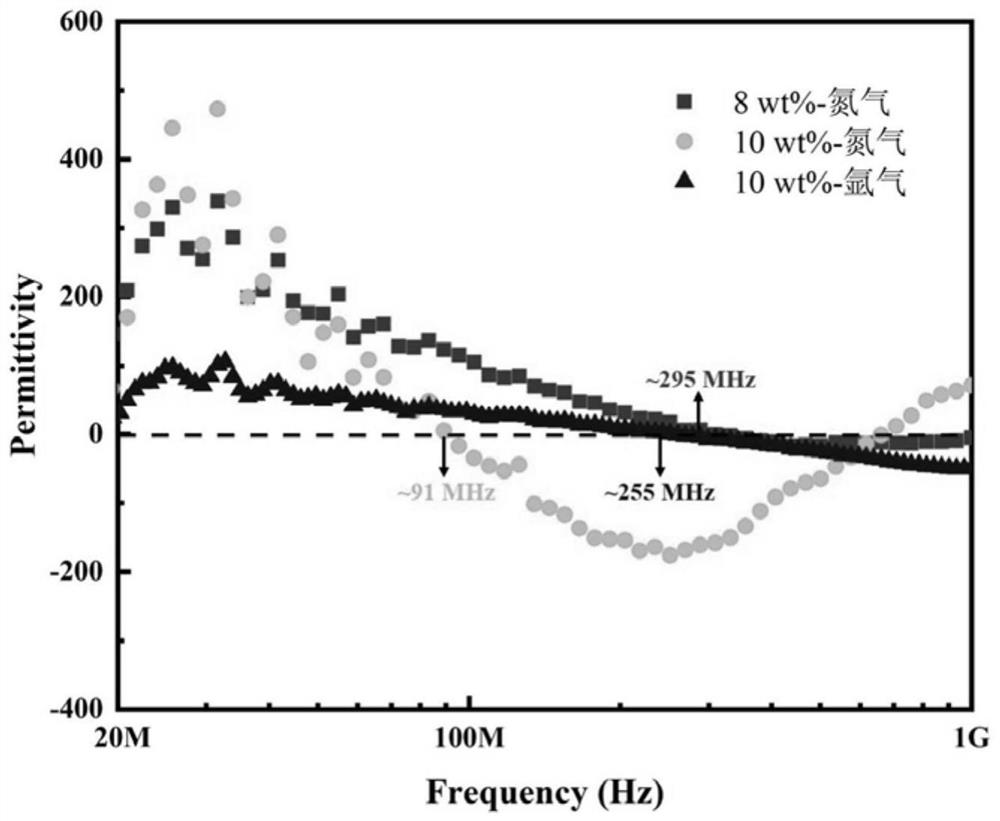

Embodiment 1

[0028] (1) Weigh titanium nitride, multi-walled carbon nanotubes and copper calcium titanate powder according to the mass ratio of 23:4:23, put them in a ball mill jar, add absolute ethanol as a ball mill medium, and Ball milled in a ball mill for 10 hours.

[0029] (2) Drying the ball-milled slurry in a vacuum drying oven, the drying temperature is 80° C., and the drying time is 12 hours. The dried powder is ground and sieved for later use.

[0030] (3) Add an appropriate amount of binder polyvinyl alcohol to titanium nitride, multi-walled carbon nanotubes and copper calcium titanate composite powder for granulation, put it into a mold and use a hydraulic press for dry pressing to obtain a disc shaped body. The pressure is 30Mpa, and the holding time is 1 minute.

[0031] (4) Put the green body into a tubular furnace filled with nitrogen for high-temperature sintering, the sintering temperature is 950°C, and the holding time is 1 hour.

[0032] (5) The titanium nitride / mu...

Embodiment 2

[0034] (1) Weigh titanium nitride, multi-walled carbon nanotubes and copper calcium titanate powder according to the mass ratio of 9:2:9, and place them in a ball mill jar, add absolute ethanol as a ball mill medium, and Ball milled in a ball mill for 10 hours.

[0035] (2) Drying the ball-milled slurry in a vacuum drying oven, the drying temperature is 80° C., and the drying time is 12 hours. The dried powder is ground and sieved for later use.

[0036] (3) Add an appropriate amount of binder polyvinyl alcohol to titanium nitride, multi-walled carbon nanotubes and copper calcium titanate composite powder for granulation, put it into a mold and use a hydraulic press for dry pressing to obtain a disc shaped body. The pressure is 30Mpa, and the holding time is 1 minute.

[0037] (4) Put the green body into a tubular furnace filled with nitrogen for high-temperature sintering, the sintering temperature is 950°C, and the holding time is 1 hour.

[0038] (5) The titanium nitrid...

Embodiment 3

[0040] (1) Weigh titanium nitride, multi-walled carbon nanotubes and copper calcium titanate powder according to the mass ratio of 9:2:9, and place them in a ball mill jar, add absolute ethanol as a ball mill medium, and Ball milled in a ball mill for 10 hours.

[0041] (2) Drying the ball-milled slurry in a vacuum drying oven, the drying temperature is 80° C., and the drying time is 12 hours. The dried powder is ground and sieved for later use.

[0042] (3) Add an appropriate amount of binder polyvinyl alcohol to titanium nitride, multi-walled carbon nanotubes and copper calcium titanate composite powder for granulation, put it into a mold and use a hydraulic press for dry pressing to obtain a disc shaped body. The pressure is 30Mpa, and the holding time is 1 minute.

[0043] (4) Put the green body into a tubular furnace filled with argon for high-temperature sintering, the sintering temperature is 950°C, and the holding time is 1 hour.

[0044] (5) The titanium nitride / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com