A polydimethylsiloxane/graphene flexible composite film with negative dielectric constant and preparation method thereof

A technology of polydimethylsiloxane and negative dielectric constant, which is applied in the field of polydimethylsiloxane/graphene flexible composite film and its preparation, can solve the problem of high dielectric loss, affecting the working performance of materials, and unfavorable Impedance matching and other issues, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

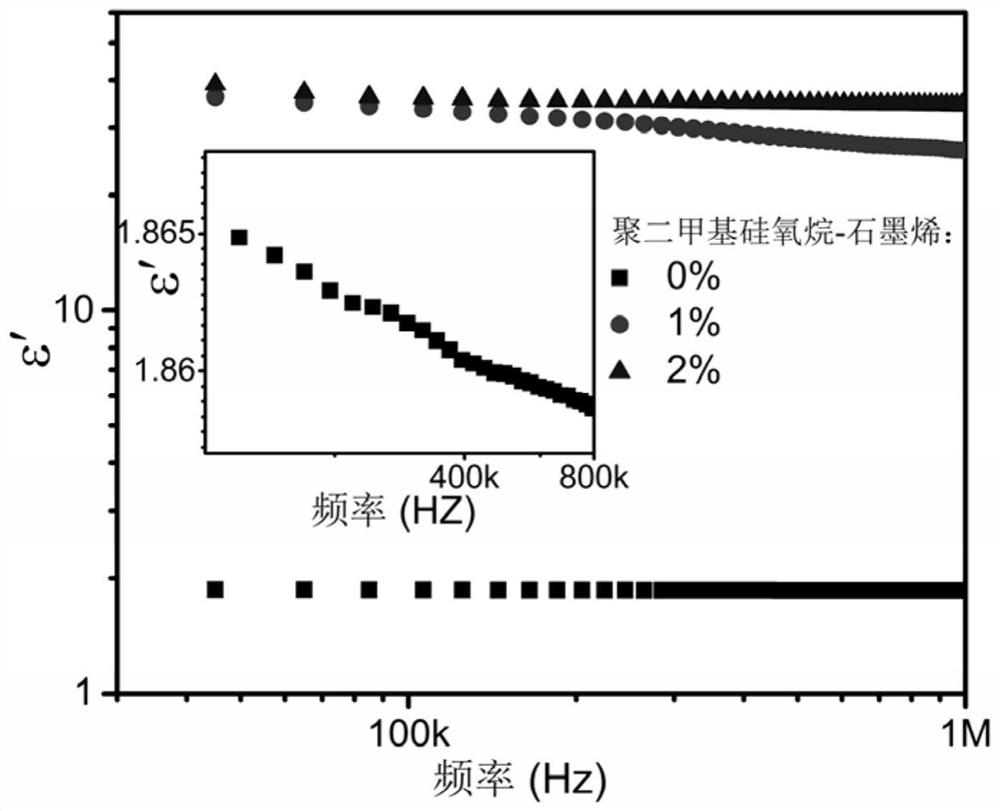

[0025] Embodiment 1 (the graphene massfraction that adds during preparation is 3%):

[0026] (1) Weigh the precursor of polydimethylsiloxane and curing agent according to the mass ratio of 10:1, wherein 2.5 grams of polydimethylsiloxane precursor and 0.25 grams of curing agent are placed in a beaker .

[0027] (2) Add 2.5 grams of n-heptane with the same mass as the precursor as a non-polar organic solvent, and perform magnetic stirring for 15 minutes to make it evenly mixed.

[0028] (3) weigh 0.162 grams of graphene, join in the above solution, carry out magnetic stirring for 30 minutes and carry out ultrasonic vibration treatment for 30 minutes, to reduce the agglomeration of graphene, obtain the mixture containing graphene and polydimethylsiloxane slurry.

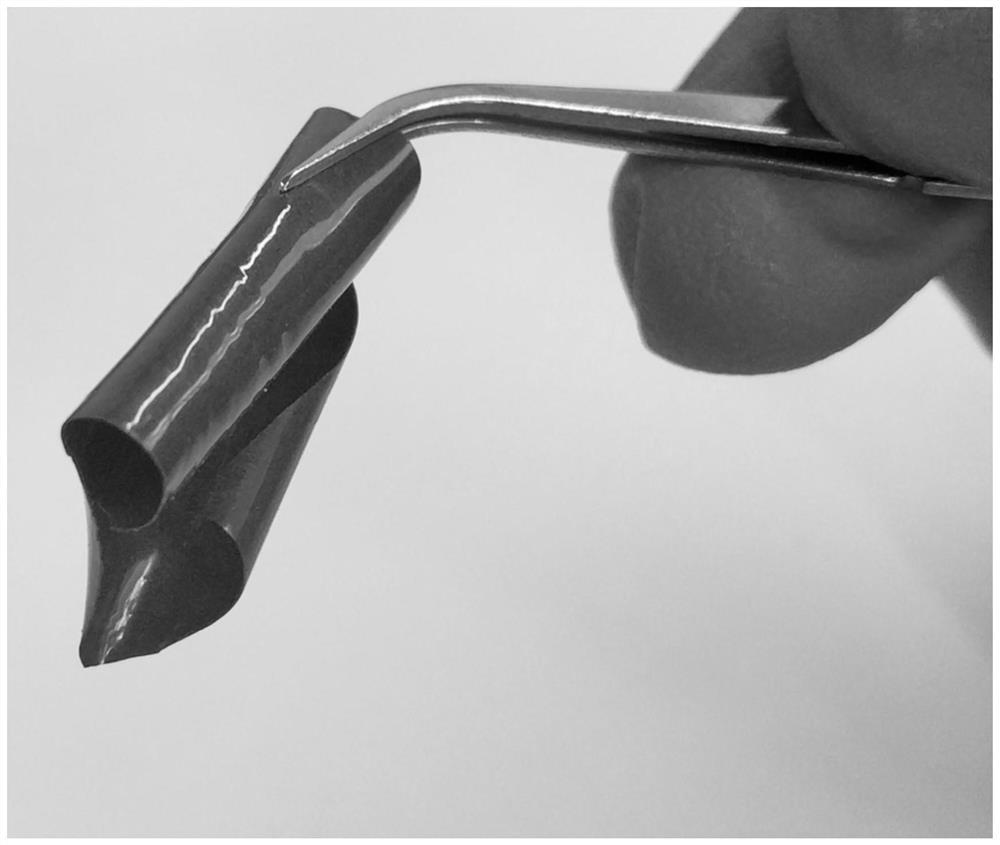

[0029] (4) After the graphene is evenly dispersed in the solution, take an appropriate amount of mixed slurry and pour it on a smooth and clean glass plate, and use a scraper (that is, use the scraping film technology...

Embodiment 2

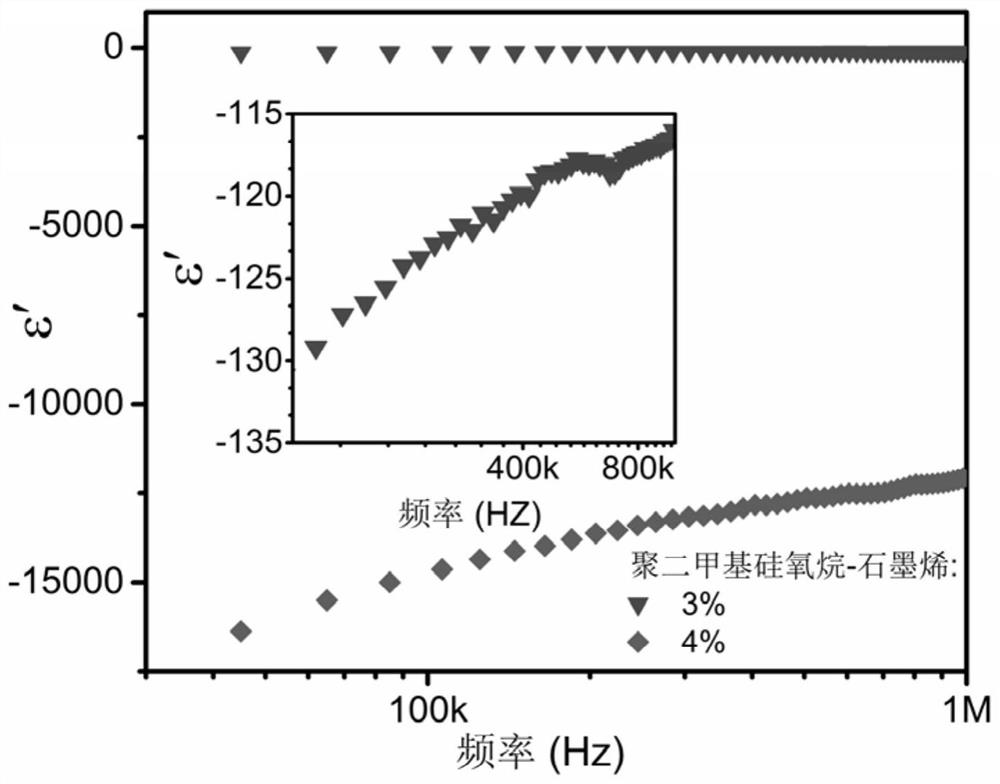

[0033] Embodiment 2 (the graphene massfraction that adds during preparation is 4%):

[0034] The difference between Example 2 and Example 1 is that the mass of graphene added in step (3) is 0.219 g, that is, the mass fraction of graphene added during preparation is 4%, and the other steps are the same. Such as figure 1 As shown, the dielectric constant of the polydimethylsiloxane / graphene flexible composite film prepared in Example 2 (4%) is negative.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com