Nanometer composite carbon black with ultrahigh sound insulation performance and preparation method thereof

A technology of sound insulation performance and composite carbon black, which is applied in the treatment of dyed low molecular organic compounds, fibrous fillers, coatings, etc., to achieve the effect of improving dispersion stability, improving sound insulation performance, and having more bubbles and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

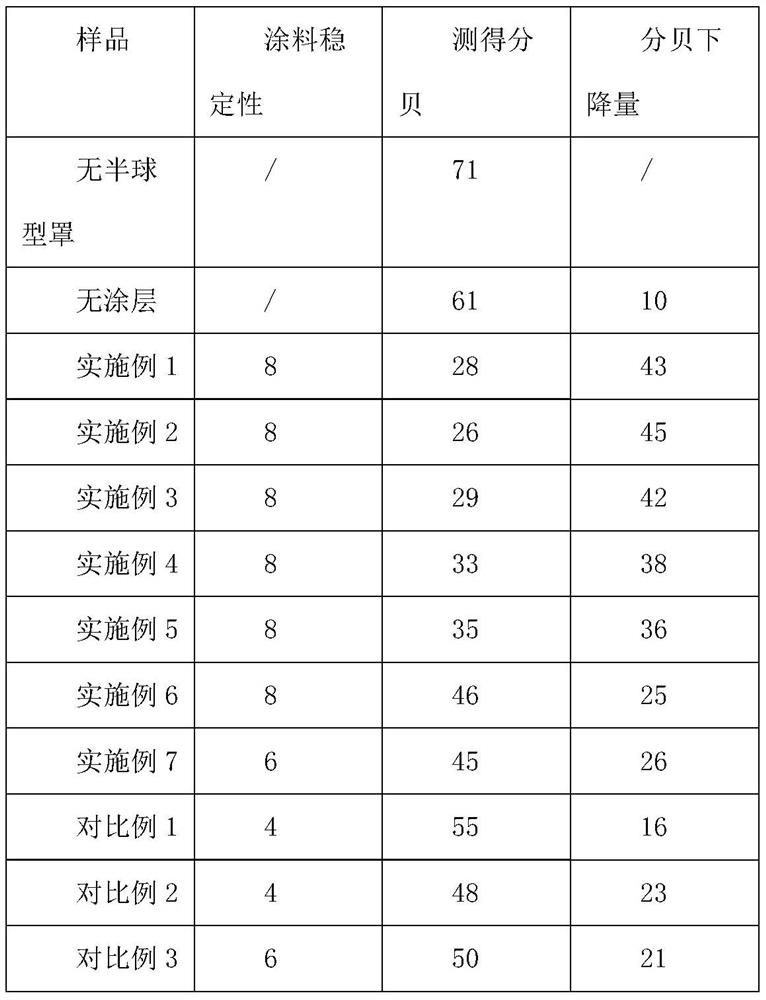

Examples

Embodiment 1

[0033] A preparation method of ultra-high sound-insulating performance nano-composite carbon black, the preparation process is as follows:

[0034] (1) Disperse the P, P-oxobisbenzenesulfonylhydrazide of 1 / 12 of the quality of nano-carbon black in ethanol with 1.5 times the quality of nano-carbon black, then add nano-carbon black, and stir evenly;

[0035] (2) Ethanol was removed by distillation under reduced pressure to obtain nano-carbon black adsorbed with P,P-oxobisbenzenesulfonyl hydrazide, and heated to 140°C for 30 minutes;

[0036] (3) Quickly introduce liquid carbon dioxide with 1.5 times the mass of nano-carbon black through the pipeline, pressurize to 7.5MPa, and heat to 35°C to become supercritical, and circulate for 10min;

[0037] (4) Reduce pressure and discharge carbon dioxide to obtain nano-composite carbon black with ultra-high sound insulation performance.

[0038] Before the 3rd step adds liquid carbon dioxide, make nano-carbon black moisture absorption re...

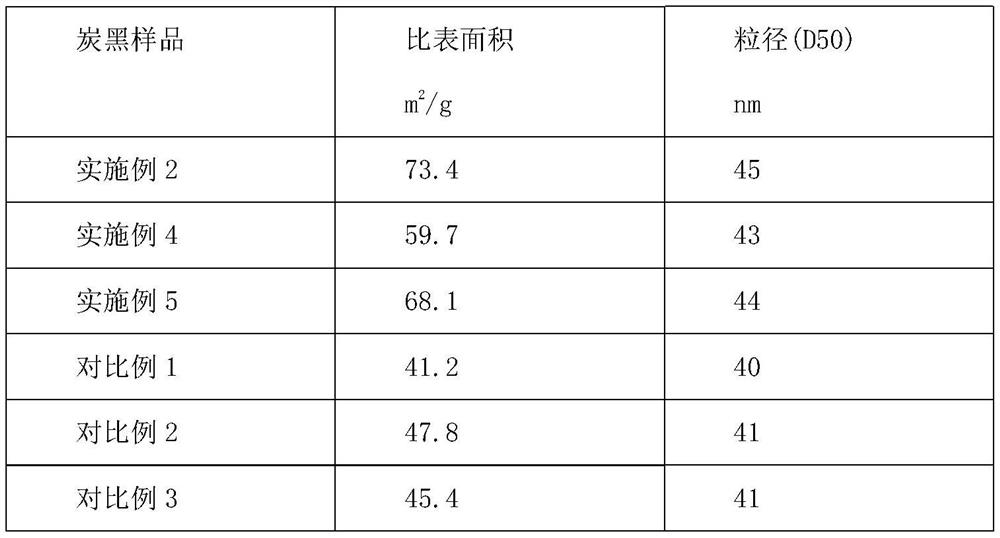

Embodiment 2

[0048] A preparation method of ultra-high sound-insulating performance nano-composite carbon black, the preparation process is as follows:

[0049] (1) Disperse the P, P-oxobisbenzenesulfonylhydrazide of nano carbon black quality 1 / 11 in the ethanol of nano carbon black quality 1.8, then add nano carbon black, stir;

[0050] (2) Ethanol was removed by distillation under reduced pressure to obtain nano-carbon black adsorbed with P,P-oxobisbenzenesulfonyl hydrazide, which was heated to 150°C for 27 minutes;

[0051] (3) Quickly introduce liquid carbon dioxide with 1.0 times the mass of nano-carbon black through the pipeline, pressurize to 7.5MPa, and heat to 35°C to become supercritical, and circulate for 15min;

[0052] (4) Reduce pressure and discharge carbon dioxide to obtain nano-composite carbon black with ultra-high sound insulation performance.

[0053] Before the 3rd step adds liquid carbon dioxide, make nano-carbon black moisture absorption reach 4% to water content; ...

Embodiment 3

[0063] A preparation method of ultra-high sound-insulating performance nano-composite carbon black, the preparation process is as follows:

[0064] (1) Disperse the P, P-oxobisbenzenesulfonylhydrazide of 1 / 10 of the nano-carbon black quality in ethanol with 2.0 times the nano-carbon black quality, then add the nano-carbon black, and stir evenly;

[0065] (2) Ethanol was removed by distillation under reduced pressure to obtain nano-carbon black adsorbed with P,P-oxobisbenzenesulfonyl hydrazide, and heated to 160°C for 20 minutes;

[0066](3) Quickly introduce liquid carbon dioxide with 0.8 times the mass of nano-carbon black through the pipeline, pressurize to 7.5MPa, and heat to 35°C to become supercritical, and circulate for 20 minutes;

[0067] (4) Reduce pressure and discharge carbon dioxide to obtain nano-composite carbon black with ultra-high sound insulation performance.

[0068] Before the 3rd step adds liquid carbon dioxide, make nano-carbon black moisture absorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com