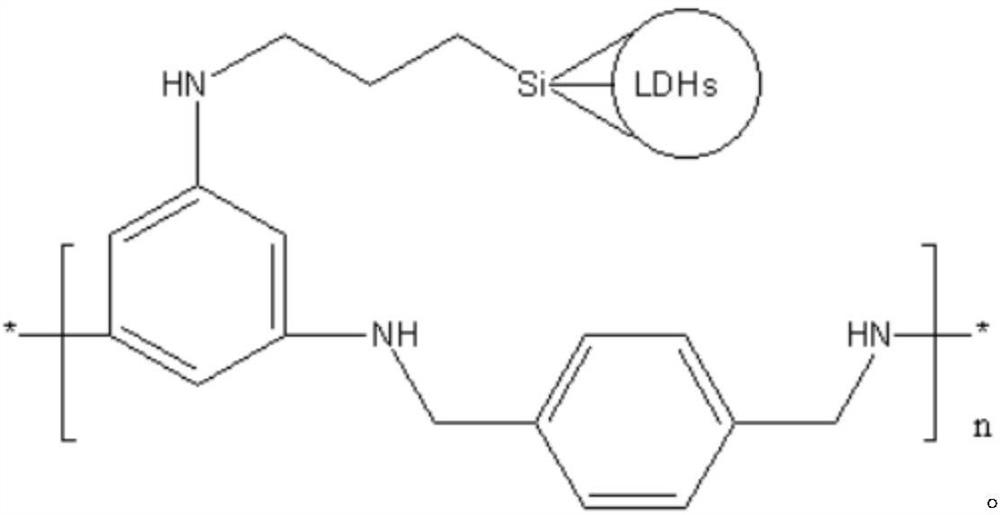

Organic-inorganic hybrid efficient synergistic flame-retardant charring agent and preparation method thereof

A char-forming agent and inorganic technology, which is applied in the field of novel organic-inorganic hybrid high-efficiency and synergistic flame-retardant char-forming agent and its preparation, can solve the problems of small molecular weight, small carbon layer force, low flame retardant efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

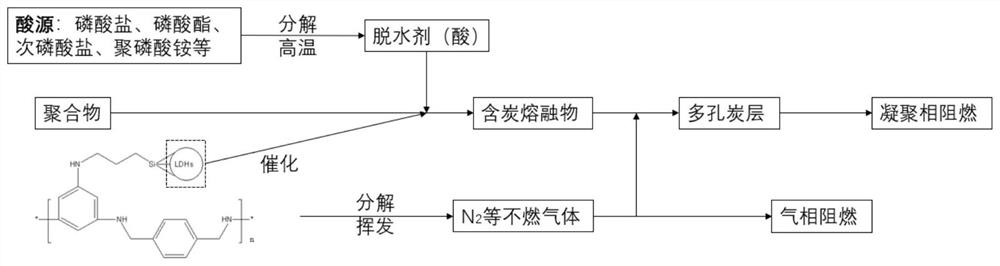

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 15

[0023] (1) Embodiment 1~Example 15 is to change the different contents of three kinds of chemically synthesized components of cyanuric chloride, p-xylylenediamine and nanometer hydrotalcite as shown in Table 1, and carry out this kind of novel organic-inorganic hybrid successively Synthesis of high-efficiency synergistic char-forming agents, and taking thermoplastic polyester elastomer (TPEE) as the application object, 15 new organic-inorganic hybrid high-efficiency synergistic char-forming agents and TPEE were sequentially synthesized to make flame-retardant TPEE materials.

[0024] Table 1 Summary of the content of different components in the synthesis of new organic-inorganic hybrid high-efficiency synergistic char-forming agents

[0025]

[0026] (2) According to the content of the components in Table 1, follow the same method and conditions as follows: add cyanuric chloride and 200mL acetone to a 500mL flask, keep the temperature of the system at 0-25°C, so that the cya...

Embodiment 16~ Embodiment 20

[0030] (1) Embodiment 16~embodiment 20 is that cyanuric chloride addition is 18g, p-xylylenediamine twice addition is respectively 3.05g and nano hydrotalcite addition is 1g, carries out this kind of novel organic- Inorganic hybrid efficient synergistic synthesis of char-forming agents.

[0031] (2) Add cyanuric chloride and 200mL acetone to a 500mL flask, keep the system temperature at 0-25°C, so that cyanuric chloride is completely dissolved, and at the same time, dissolve p-xylylenediamine and 4.00g sodium hydroxide in 20mL In deionized water, drop it into the reaction system dropwise within 0.5~2h, and keep the reaction at 0~25°C for 2.5~7h after the dropwise addition. After the reaction, the temperature of the reaction system was raised to 40-60°C, and then the aqueous solution of p-xylylenediamine (the amount of p-xylylenediamine added twice) and sodium hydroxide (4.00g) was added dropwise to the above-mentioned For the reaction system, at this temperature, the dropping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com