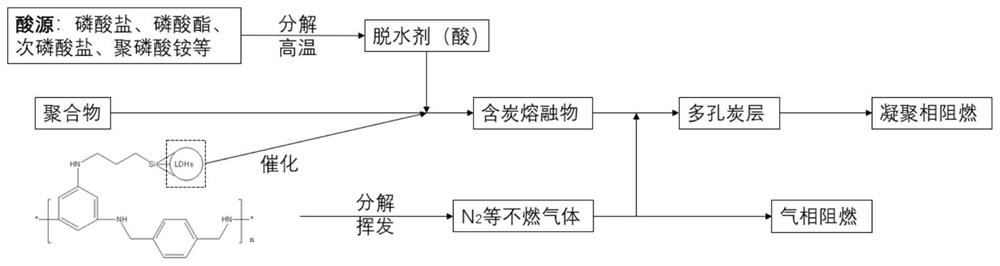

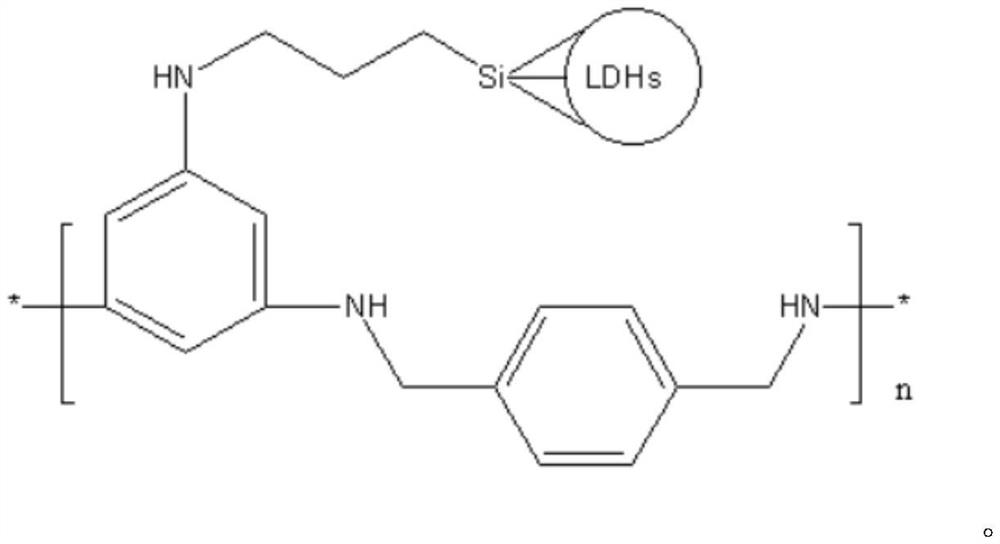

An organic-inorganic hybrid high-efficiency synergistic flame-retardant char-forming agent and its preparation method

A char-forming agent and inorganic technology, applied in the field of novel organic-inorganic hybrid high-efficiency synergistic flame-retardant char-forming agent and its preparation, can solve the problems of poor compatibility, unsatisfactory flame retardant effect, small molecular weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 15

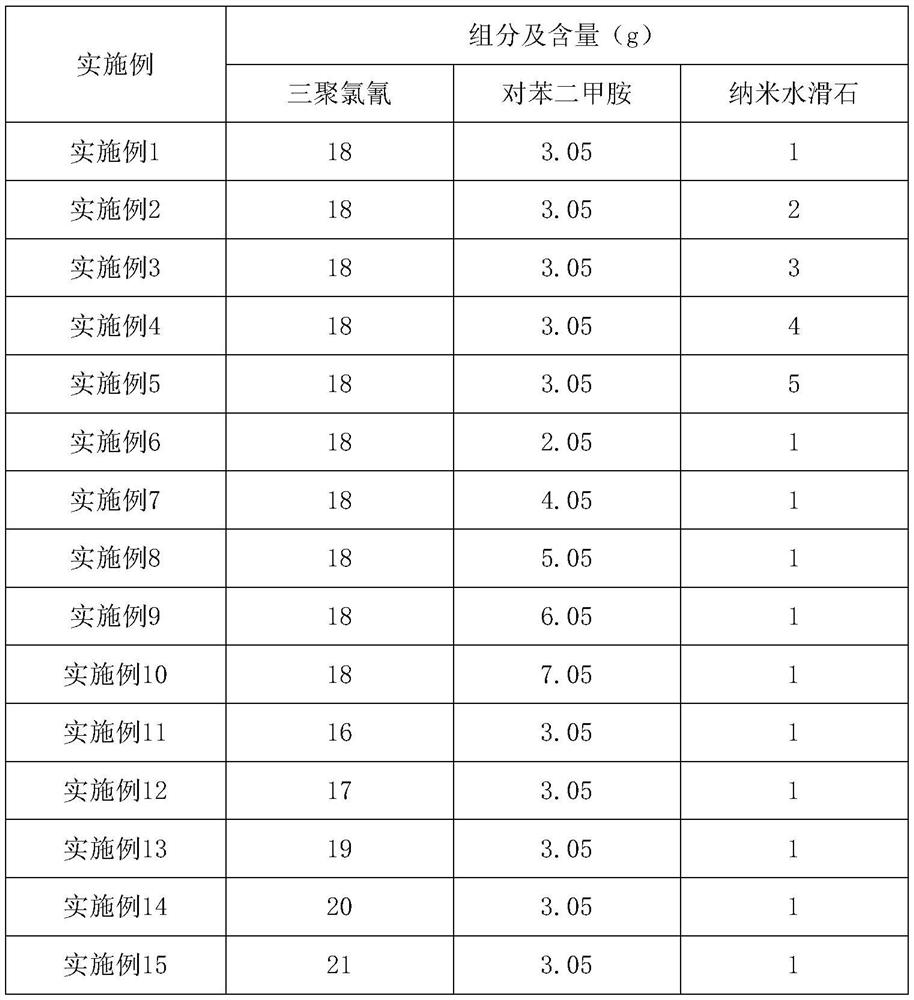

[0023] (1) Examples 1 to 15 are to change the different contents of the three chemical synthesis components of cyanuric chloride, p-xylylenediamine and nano-hydrotalcite as shown in Table 1, and sequentially carry out the new organic-inorganic hybrid Synthesis of chemically efficient synergistic char-forming agent, and taking thermoplastic polyester elastomer (TPEE) as the application object, 15 new organic-inorganic hybrid high-efficiency synergistic char-forming agents and TPEE were synthesized in turn to make flame retardant TPEE materials.

[0024] Table 1 Summary of the contents of different components in the synthesis of novel organic-inorganic hybrid high-efficiency synergistic char-forming agents

[0025]

[0026] (2) According to the component content in Table 1, operate according to the following identical methods and conditions in turn: add cyanuric chloride and 200 mL of acetone into the 500 mL flask, keep the system temperature at 0 to 25°C, and make the cyanuri...

Embodiment 16~ Embodiment 20

[0030] (1) In Examples 16 to 20, the addition amount of cyanuric chloride is 18g, the addition amount of p-xylylenediamine is 3.05g and the addition amount of nano-hydrotalcite is 1g, respectively, to carry out this kind of new organic- Synthesis of Inorganic Hybrid Efficient Synergistic Carbon-forming Agents.

[0031] (2) Add cyanuric chloride and 200 mL of acetone into a 500 mL flask, keep the temperature of the system at 0 to 25° C. to completely dissolve the cyanuric chloride, and at the same time, dissolve p-xylylenediamine and 4.00 g of sodium hydroxide in 20 mL of In deionized water, drop it into the reaction system dropwise within 0.5 to 2 hours, and keep the reaction at 0 to 25° C. for 2.5 to 7 hours after the dropwise addition. After the reaction is completed, the reaction system is heated to 40~60 ℃, then the aqueous solution of p-xylylenediamine (the same amount of p-xylylenediamine added twice) and sodium hydroxide (4.00g) is added dropwise to the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com