Preparation method of concrete expanding agent

A technology of expansive agent and concrete, which is applied in the field of concrete, can solve the problems of poor stability of the expansive effect of concrete expansive agent, and achieve the effects of ensuring stability, promoting hydration, and compensating for shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

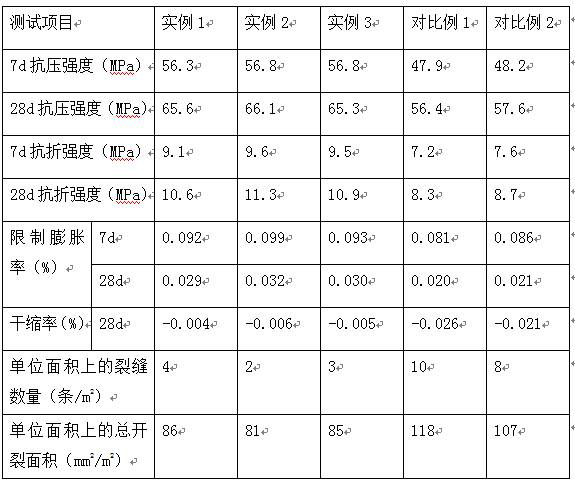

Examples

preparation example Construction

[0022] The preparation method of the mixture is: stir and mix the aluminum ash, barium oxide and nitric acid solution at a mass ratio of 1:0.1-0.3:5-7, then add polyacrylamide with an aluminum ash mass of 8-11%, and stir at 800r / min 30min, stand still for 1-3h, and spray dry to obtain the mixture.

[0023] The additive is prepared by mixing ferric sulfate and ferrous chloride in a mass ratio of 4:3-6.

[0024] The auxiliary materials are polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer and tung oil mixed in a mass ratio of 3:1-2 to obtain the product.

[0025] The pore forming agent is any one of ammonium bicarbonate and sodium bicarbonate.

[0026] The dispersant is any one of polyethylene glycol and fatty acid polyethylene glycol ester.

[0027] The mixed solvent is made by mixing sodium hydroxide solution and acetone at a volume ratio of 8:3-5.

[0028] The wrapping agent is made by mixing sodium alginate and maleic anhydride in a mass ratio o...

Embodiment 1

[0035] The preparation method of the mixture is: stir and mix aluminum ash, barium oxide and nitric acid solution at a mass ratio of 1:0.3:7, then add polyacrylamide with 11% aluminum ash mass, stir at 800r / min for 30min, and let stand for 3h. Spray drying to obtain the mixture.

[0036] The additive is prepared by mixing ferric sulfate and ferrous chloride in a mass ratio of 4:6.

[0037] The auxiliary material is polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer and tung oil mixed at a mass ratio of 3:2 to obtain the product.

[0038] The pore former is sodium bicarbonate.

[0039] The dispersant is fatty acid polyethylene glycol ester.

[0040] The mixed solvent is sodium hydroxide solution and acetone mixed at a volume ratio of 8:5.

[0041] The coating agent is made by mixing sodium alginate and maleic anhydride in a mass ratio of 9:4.

[0042] A preparation method of concrete expansive agent, the preparation method comprises the steps of: ...

Embodiment 2

[0048] The preparation method of the mixture is: stir and mix aluminum ash, barium oxide and nitric acid solution at a mass ratio of 1:0.2:6, then add polyacrylamide with an aluminum ash mass of 8-11%, stir at 800r / min for 30min, and let stand 2h, spray drying to obtain the mixture.

[0049] The additive is prepared by mixing ferric sulfate and ferrous chloride at a mass ratio of 4:5.

[0050] The auxiliary material is polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer and tung oil mixed at a mass ratio of 3:1.5 to obtain the product.

[0051] The pore former is ammonium bicarbonate.

[0052] The dispersant is polyethylene glycol.

[0053] The mixed solvent is made by mixing sodium hydroxide solution and acetone in a volume ratio of 8:4.

[0054] The coating agent is made by mixing sodium alginate and maleic anhydride in a mass ratio of 9:3.

[0055] A preparation method of concrete expansive agent, the preparation method comprises the steps of: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com