Method for removing humic acid by limited catalytic flocculation to improve sludge liquid state fermentation acid production

A liquid fermentation, humic acid technology, applied in chemical instruments and methods, fermentation, pyrolysis treatment of sludge, etc., can solve the problem of large consumption of catalyst and light energy, etc., to achieve short ultraviolet light time, less secondary pollution, oxidation powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 adopts the effect of the sludge liquid fermentation acid production after the method of the present invention

[0038] (1) Adjust the municipal sludge to a sludge concentration of 100g / L, and then perform thermal hydrolysis in a high-temperature and high-pressure reactor at a temperature of 180°C for 0.5h and a voltage of 75V to release the organic matter in the sludge into the liquid phase;

[0039] (2) The reactant obtained in step (1) is subjected to solid-liquid separation to remove inorganic and biologically refractory solid phase residues to obtain a sludge hydrolyzate containing high-concentration soluble organic matter. At this time, in the sludge hydrolyzate The zeta potential of humic acid is -3.0mV;

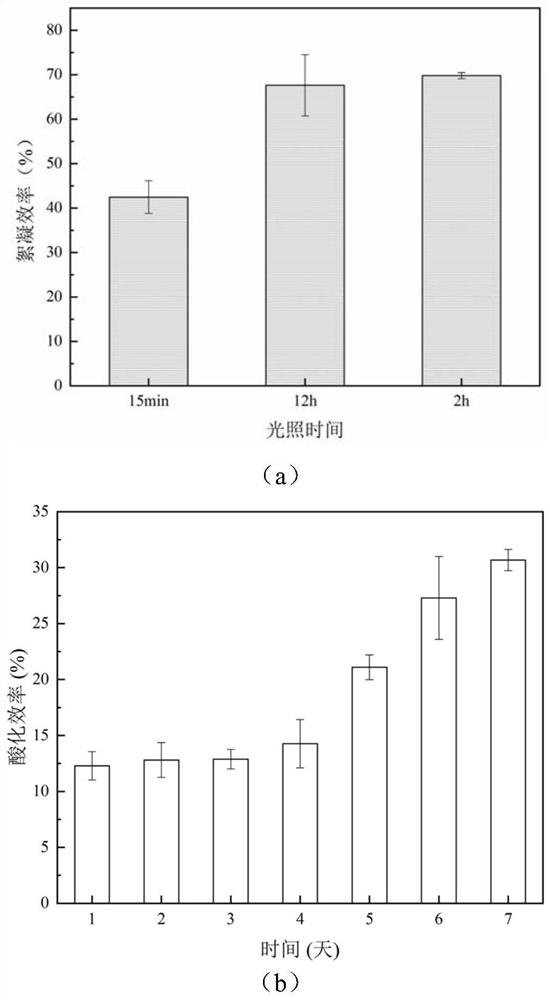

[0040] (3) In the sludge hydrolyzate obtained in step (2), add TiO in an amount of 300 mg per L of sludge hydrolyzate 2 , after stirring evenly, irradiate with ultraviolet light, the output power of ultraviolet light is 10W, and the irradiation ti...

Embodiment 2

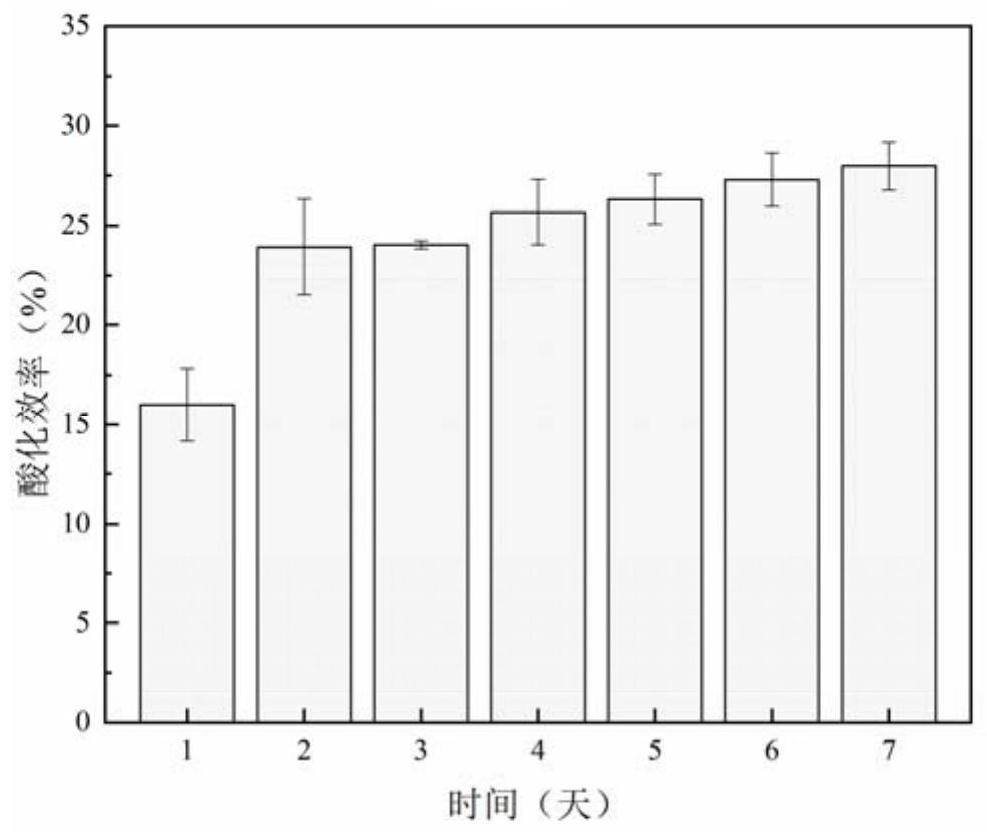

[0045] (1) Adjust the municipal sludge to a sludge concentration of 50g / L, and then perform thermal hydrolysis in a high-temperature and high-pressure reactor at a temperature of 140°C for 0.5h and a voltage of 75V to release the organic matter in the sludge into the liquid phase;

[0046] (2) The reactant obtained in step (1) is subjected to solid-liquid separation to remove inorganic and biologically refractory solid phase residues to obtain a sludge hydrolyzate containing high-concentration soluble organic matter. At this time, in the sludge hydrolyzate The zeta potential of humic acid is -2.0mV;

[0047] (3) In the sludge hydrolyzate obtained in step (2), add TiO in an amount of 50 mg per L of sludge hydrolyzate 2 , after stirring, irradiate with ultraviolet light, the output power of ultraviolet light is 10W, and the irradiation time is 3.0h. At this time, the zeta potential of humic acid in the sludge hydrolyzate is -20.0mV;

[0048] (4) In the system of step (3), add ...

Embodiment 3

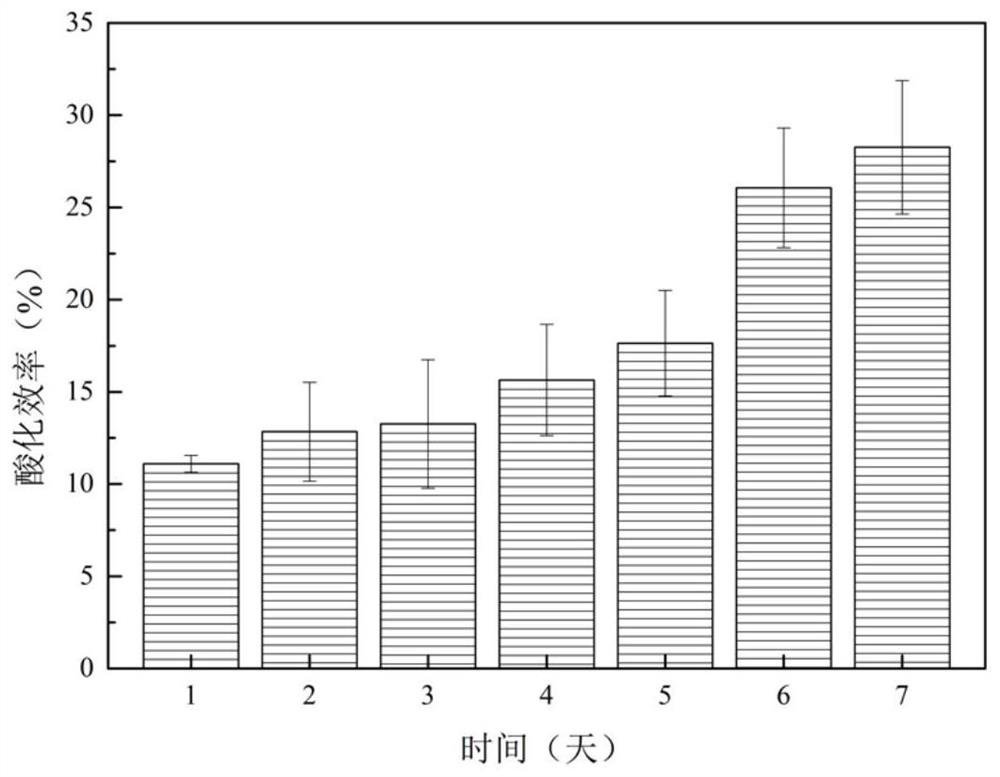

[0052] (1) Adjust the municipal sludge to a sludge concentration of 150g / L, and then perform thermal hydrolysis in a high-temperature and high-pressure reactor at a temperature of 220°C for 0.5h and a voltage of 100V to release the organic matter in the sludge into the liquid phase;

[0053] (2) The reactant obtained in step (1) is subjected to solid-liquid separation to remove inorganic and biologically refractory solid phase residues to obtain a sludge hydrolyzate containing high-concentration soluble organic matter. At this time, in the sludge hydrolyzate The zeta potential of humic acid is -10.0mV;

[0054] (3) In the sludge hydrolyzate obtained in step (2), add TiO in an amount of 300 mg per L of sludge hydrolyzate 2 , after stirring evenly, irradiate with ultraviolet light, the output power of ultraviolet light is 20W, and the irradiation time is 3.0h. At this time, the zeta potential of humic acid in the sludge hydrolyzate is-35mV;

[0055] (4) In the system of step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com