Square battery lower box body structure

A box structure, square battery technology, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of increasing manufacturing cost, high manufacturing cost and price, increasing the difficulty of sheet metal stamping, etc., to reduce the overall height or Thickness, reliable fixation and assembly, and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

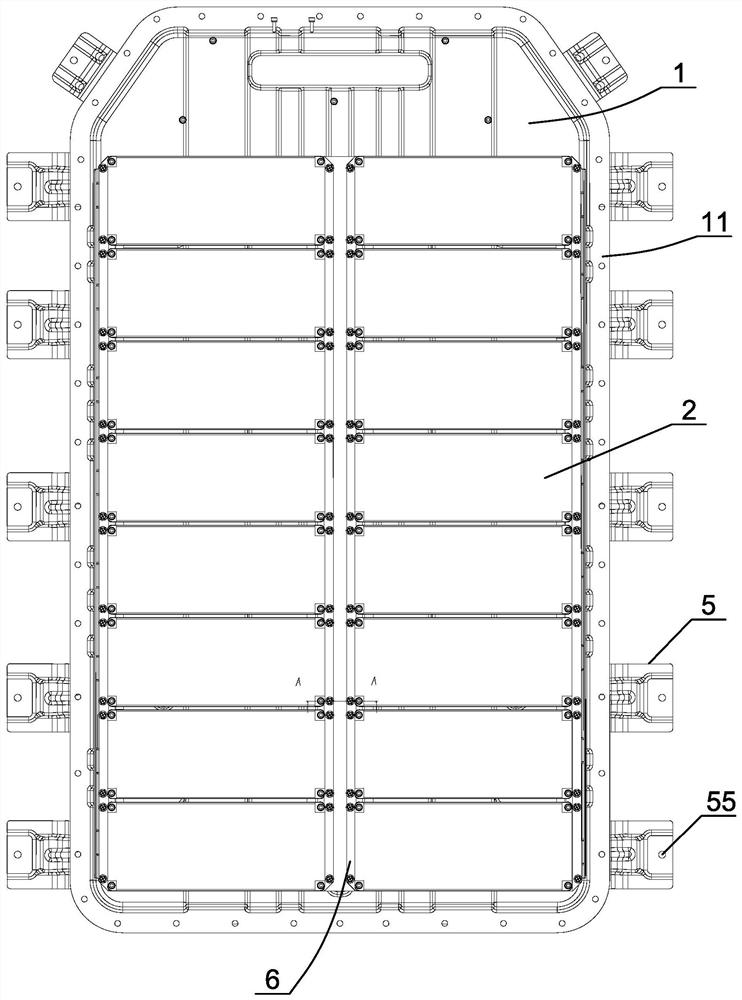

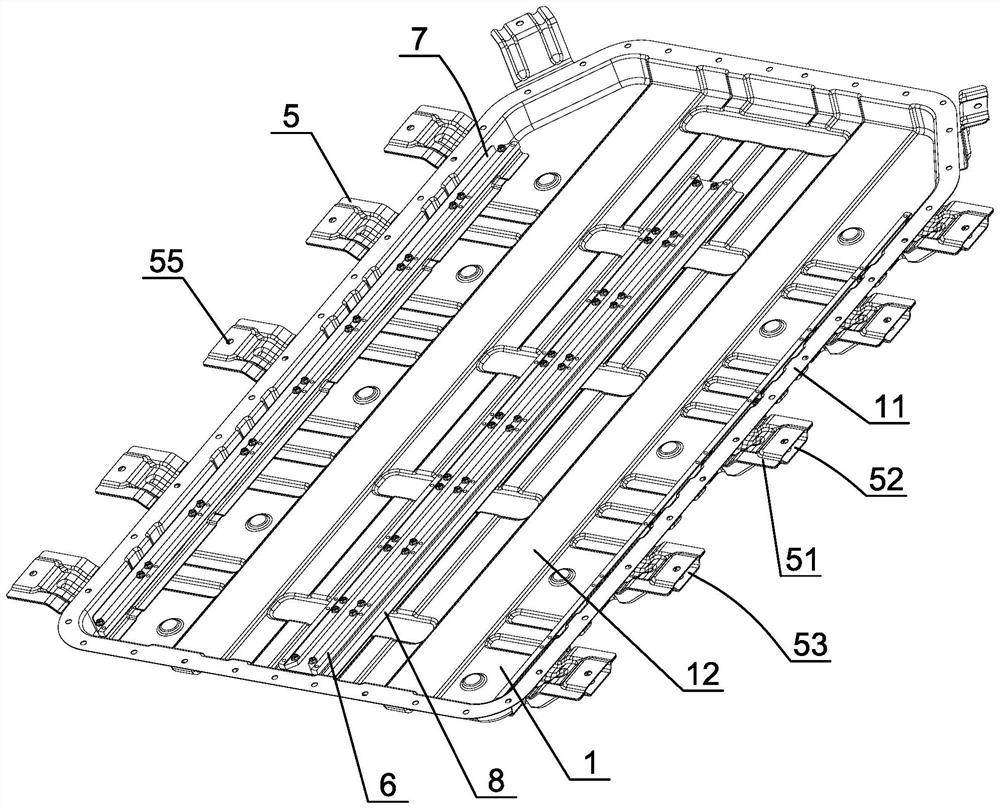

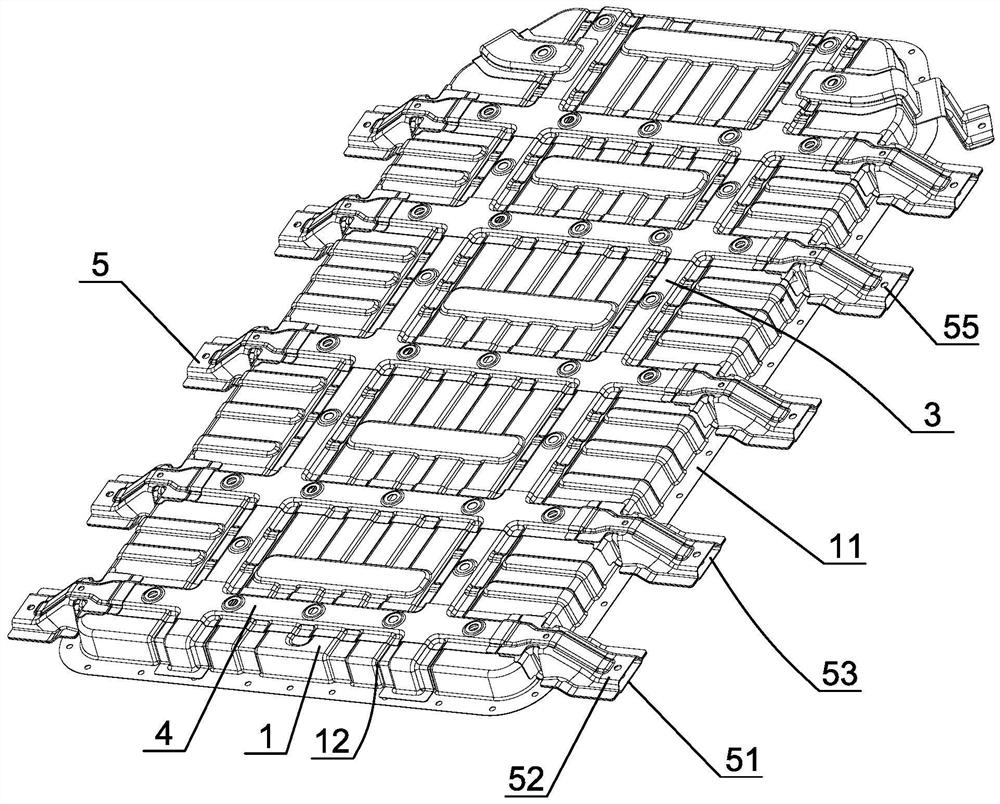

[0044] Such as figure 1 As shown, a lower box structure of a square battery, the square battery includes a lower box and an upper box, since the upper box is not a load-bearing part, the present invention does not improve the existing structure of the upper box, so No detailed description is given in this embodiment. Specifically, the present invention includes a rectangular lower case 1 formed from sheet metal, and left and right battery modules 2 arranged on the lower case, and each battery module group includes 8 battery units arranged longitudinally.

[0045] It should be noted that, in this embodiment, the length direction of the lower casing is referred to as the longitudinal direction, and the width direction is referred to as the transverse direction.

[0046] In addition, the periphery of the lower casing is provided with a flange 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com