Regeneration process of waste lithium iron phosphate battery cathode material

A technology for lithium iron phosphate batteries and positive electrode materials, applied in battery electrodes, lithium batteries, battery recycling, etc., can solve the problems of inability to obtain economic benefits, high equipment and operation requirements, high recycling costs, etc., and achieve fine grain size , low recycling cost, good market prospects and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

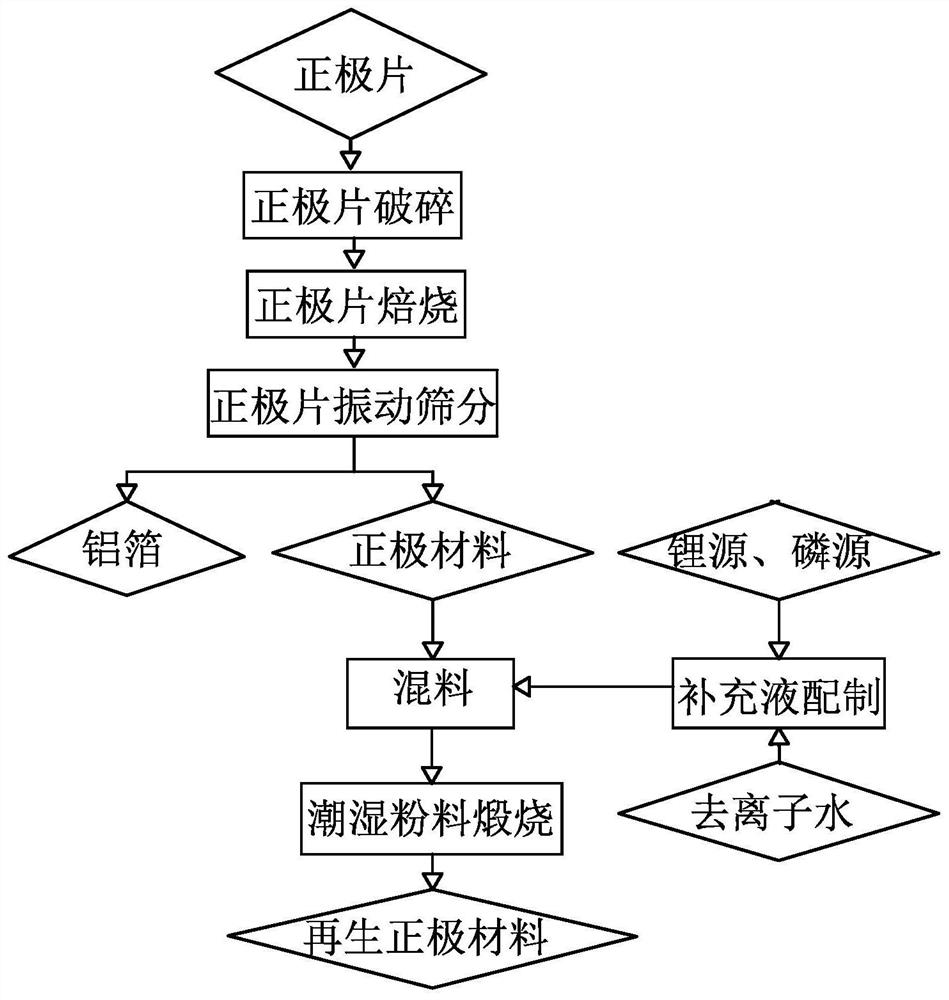

Method used

Image

Examples

Embodiment 1

[0033] According to the actual situation, operate as follows:

[0034] (1) Add 200 positive pole pieces to the crusher, start the machine and tear the strip-shaped pole pieces into flakes, and collect them for later use;

[0035] (2) Put the broken positive electrode sheet into the metal tray, then push it into the ultra-high temperature oven, close the oven door and then vacuumize, stop vacuuming when the vacuum degree reaches 3Pa, and inject nitrogen until the pressure is a slight positive pressure of 2.5 kPa, turn on the oven, heat up to 410°C, and keep it warm for 1h;

[0036] (3) Add the baked positive electrode sheet into the ultrasonic vibrating sieve, and turn on the ultrasonic vibrating sieve. After ultrasonic vibration, the aluminum foil is sieved from the upper discharge port, and the aluminum foil is recycled; the positive electrode material is screened out from the lower discharge port through the screen, and the positive electrode material is collected for later...

Embodiment 2

[0042] According to the actual situation, operate as follows:

[0043] (1) Add 200 positive pole pieces to the crusher, start the machine and tear the strip-shaped pole pieces into flakes, and collect them for later use;

[0044] (2) Put the broken positive electrode sheet into the metal tray, and then push it into the ultra-high temperature oven, close the oven door and vacuumize, stop vacuuming when the vacuum degree reaches 3Pa, and feed ammonia decomposition gas until the pressure is slightly positive Pressure 3kPa, turn on the oven, heat up to 470°C, keep warm for 0.5h;

[0045] (3) Add the baked positive electrode sheet into the ultrasonic vibrating sieve, and turn on the ultrasonic vibrating sieve. After ultrasonic vibration, the aluminum foil is sieved from the upper discharge port, and the aluminum foil is recycled; the positive electrode material is screened out from the lower discharge port through the screen, and the positive electrode material is collected for la...

Embodiment 3

[0051] According to the actual situation, operate as follows:

[0052] (1) Add 200 positive pole pieces to the crusher, start the machine and tear the strip-shaped pole pieces into flakes, and collect them for later use;

[0053] (2) Put the broken positive electrode sheet into the metal tray, and then push it into the ultra-high temperature oven, close the oven door and vacuumize, stop vacuuming when the vacuum degree reaches 3Pa, and introduce argon gas until the pressure is a slight positive pressure 1kPa, turn on the oven, heat up to 410°C, and keep warm for 0.5h;

[0054] (3) Add the baked positive electrode sheet into the ultrasonic vibrating sieve, and turn on the ultrasonic vibrating sieve. After ultrasonic vibration, the aluminum foil is sieved from the upper discharge port, and the aluminum foil is recycled; the positive electrode material is screened out from the lower discharge port through the screen, and the positive electrode material is collected for later use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com