Bearing lubricating film thickness ultrasonic measurement method and system

A technology of ultrasonic measurement and bearing lubrication, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic, instruments, etc., can solve the problem of inability to effectively monitor the real-time and continuous changes of the bearing lubricating film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

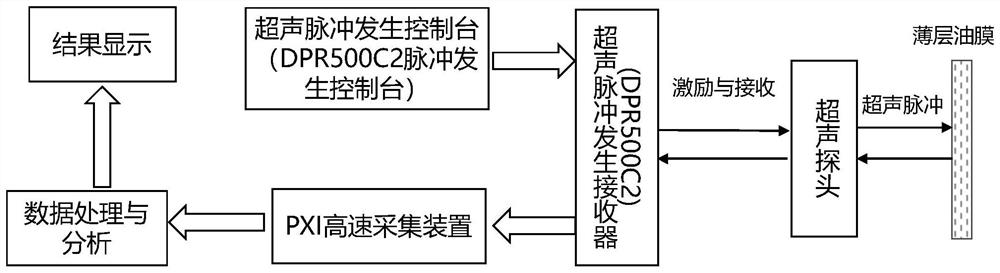

[0034] Specific implementation mode 1: The ultrasonic measurement method for bearing lubricating film thickness described in this implementation mode is specifically implemented through the following steps:

[0035] Step 1, using an ultrasonic probe to obtain an initial reference signal;

[0036] Step 2, when the bearing is running, obtain the ultrasonic reflection pulse signal of the lubricating oil film layer;

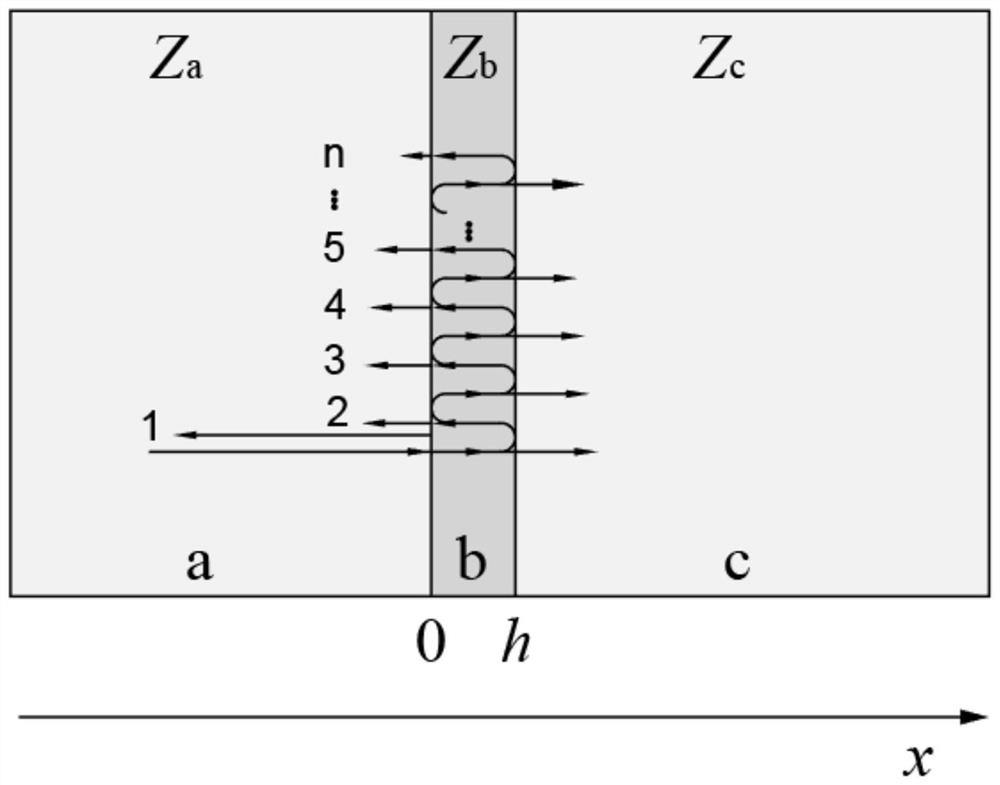

[0037] Step 3, performing fast Fourier transform on the reference signal collected in step 1 and the reflected pulse signal collected in step 2, respectively, to obtain the reflection coefficient of the lubricating film layer;

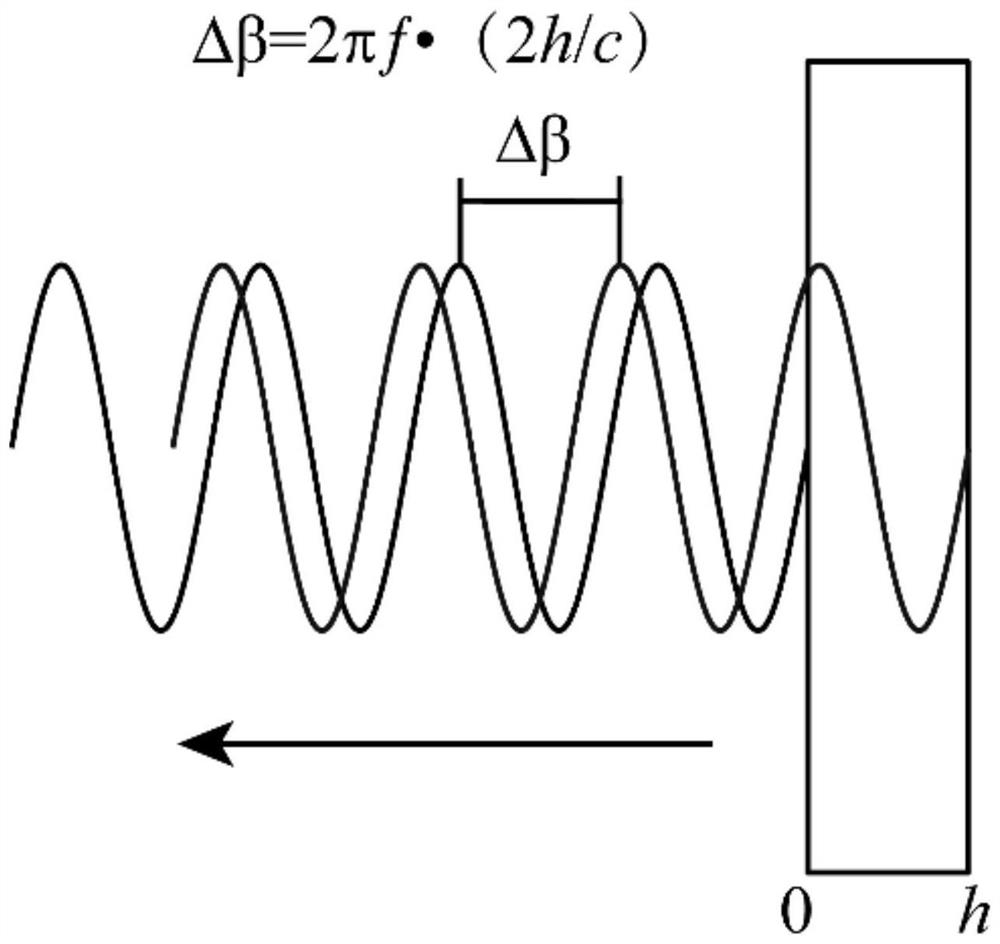

[0038] Step 4, using the lubricating film layer reflection coefficient obtained in step 3 to calculate the phase angle at which the latter reflected wave lags behind the previous reflected wave;

[0039] Step 5, based on the phase angle of the latter reflected wave calculated in step 4 lagging behind the previous reflected wave, the thicknes...

specific Embodiment approach 2

[0041] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the specific process of the step one is:

[0042] When the bearing has no lubricating film or the thickness of the lubricating film is greater than 300 μm, the ultrasonic probe is used to collect the reflected pulse wave of the reference interface, and the collected reflected pulse wave is used as the initial reference signal.

specific Embodiment approach 3

[0043] Specific implementation mode three: the difference between this implementation mode and specific implementation mode two is: the specific process of the step three is:

[0044] Fast Fourier transform is performed on the reflected pulse signal of the oil film layer to obtain the Fourier transform value A m , perform fast Fourier transform on the reference signal to obtain the Fourier transform value A ref ; Then the reflection coefficient of the oil film layer is obtained based on the following formula;

[0045]

[0046] Among them: R is the reflection coefficient of the lubricating film layer, R ref is the reference reflection coefficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com