Polycarbonate engineering plastic with electromagnetic shielding and heat conduction functions and preparation method thereof

A polycarbonate, electromagnetic shielding technology, applied in the field of engineering plastics, can solve the problem of no polycarbonate engineering plastics, and achieve the effects of reducing weight and volume occupation, high injection molding accuracy, and excellent electromagnetic shielding and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

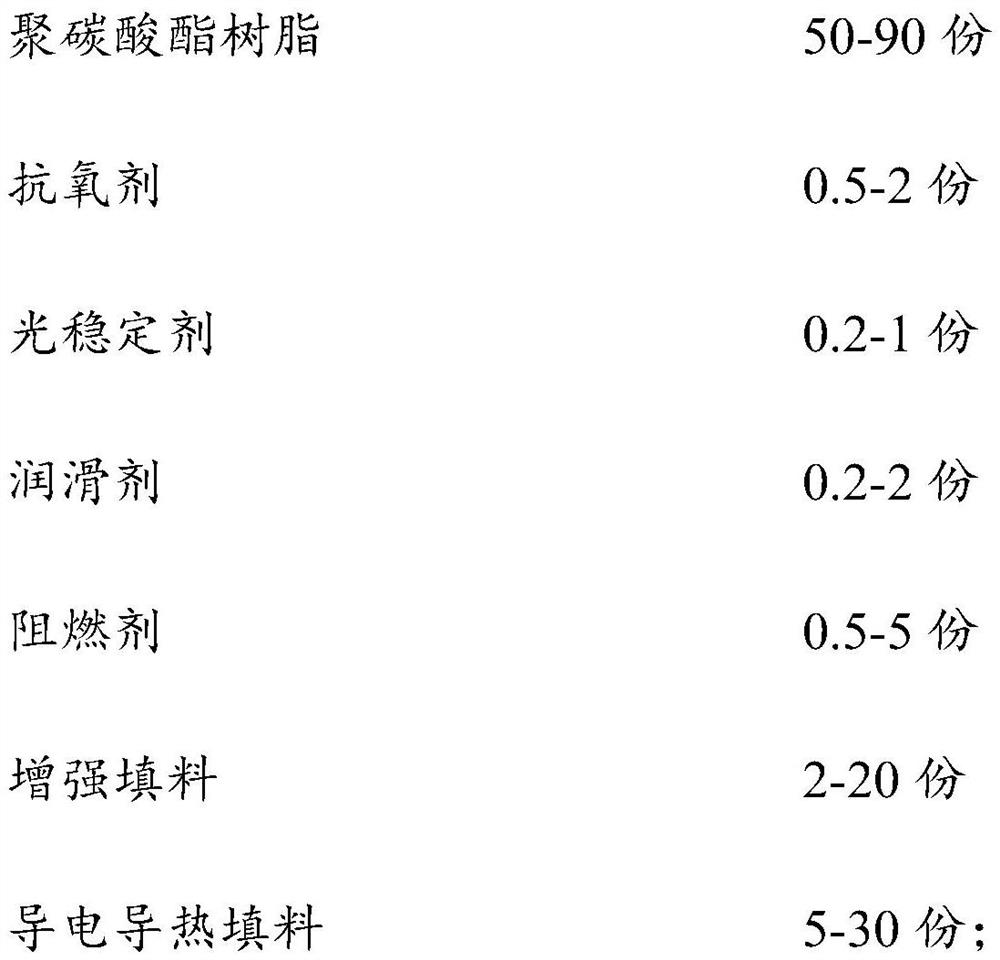

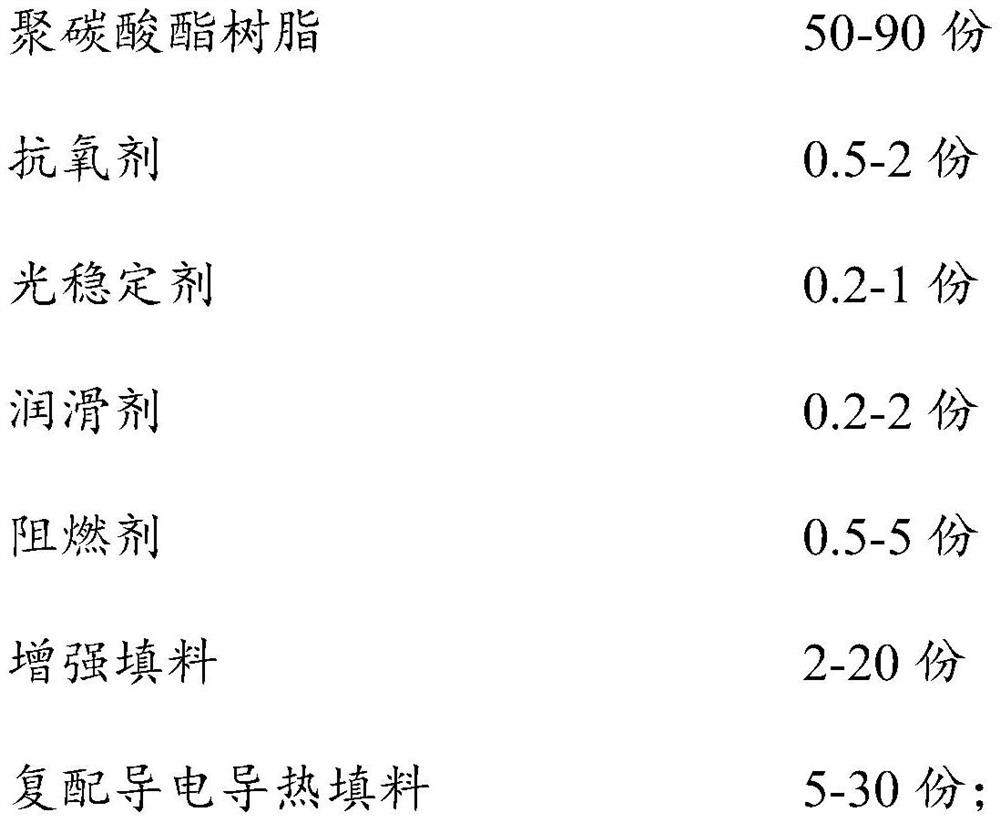

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a polycarbonate engineering plastic with both electromagnetic shielding and heat conduction functions, and its preparation method is as follows:

[0026] According to the ratio in Table 1, mix the components other than the reinforcing fiber into the twin-screw extruder, add the reinforcing fiber at the side feeding port, extrude and granulate, and obtain the polycarbonate polycarbonate with both electromagnetic shielding and heat conduction functions. Ester engineering plastics.

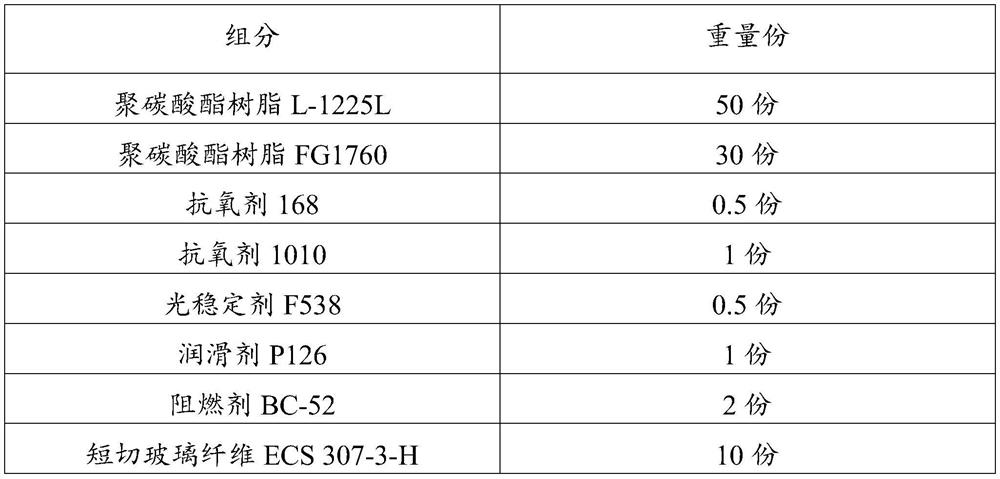

[0027] The formula of the polycarbonate engineering plastics of table 1 embodiment 1

[0028]

[0029]

Embodiment 2

[0031] This embodiment provides a polycarbonate engineering plastic with both electromagnetic shielding and heat conduction functions, and its preparation method is as follows:

[0032] According to the ratio in Table 2, mix the components other than the reinforcing fiber into the twin-screw extruder, add the reinforcing fiber at the side feed port, extrude and granulate, and obtain the polycarbonate polycarbonate with both electromagnetic shielding and heat conduction functions. Ester engineering plastics.

[0033] The formula of the polycarbonate engineering plastics of table 2 embodiment 2

[0034] components parts by weight Polycarbonate resin L-1225L 50 copies Polycarbonate resin FG1760 30 copies Antioxidant 168 0.5 parts Antioxidant 1010 1 copy Light stabilizer F538 0.5 parts Lubricant P126 1 copy Flame retardant BC-52 2 copies Chopped carbon fiber T700-SC 5 copies Expanded graphite EG-3 15 copies ...

Embodiment 3

[0036] This embodiment provides a polycarbonate engineering plastic with both electromagnetic shielding and heat conduction functions, and its preparation method is as follows:

[0037] According to the ratio in Table 3, mix the components other than the reinforcing fiber into the twin-screw extruder, add the reinforcing fiber at the side feed port, extrude and granulate, and obtain the polycarbonate polycarbonate with both electromagnetic shielding and heat conduction functions. Ester engineering plastics.

[0038] The formula of the polycarbonate engineering plastics of table 3 embodiment 3

[0039] components parts by weight Polycarbonate resin L-1225Y 50 copies Polycarbonate resin FG1760 30 copies Antioxidant 168 0.5 parts Antioxidant 1010 1 copy Light stabilizer F538 0.5 parts Lubricant P126 1 copy Flame retardant BC-52 2 copies Chopped Glass Fiber ECS 307-3-H 10 copies Chopped Stainless Steel Fiber G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com