Continuous preparation method of semi-aromatic polyamide with low oligomer content and product thereof

A semi-aromatic and oligomer technology, which is applied in the field of continuous preparation of semi-aromatic polyamides, can solve the problems of low oligomer content and semi-aromatic polyamides, difficulty in meeting large production needs, unsatisfactory effects, and the like. Narrow molecular weight distribution, optimal mass transfer, and reduced oligomer content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

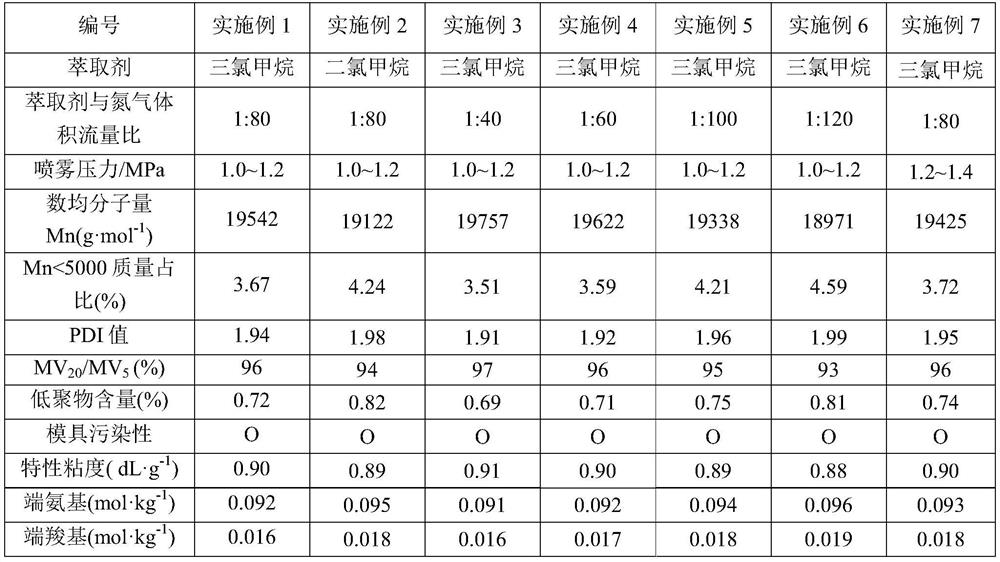

Embodiment 1

[0100]According to the ratio of 0.95 of the initial feeding amine acid ratio, 4.57kg / h (27.5mol / h) terephthalic acid, 3.29kg / h (22.5mol / h) adipic acid, 5.52kg / h (47.5mol / h) Hexamethylenediamine, 0.05kg / h of 20wt% sodium hypophosphite aqueous solution and 5.72kg / h of water are put into the beating kettle 9, and continuously beating at 80°C to form a slurry. The slurry is transported by pump 10 to multi-stage stirring dissolution tank 14 and heated to 150° C. to dissolve into salt with the steam generated in the dehydration process. According to the composition of the dibasic acid in the salt solution detected by the on-line Raman spectrum 18, the amount of the aliphatic dibasic acid is adjusted by using molten adipic acid through the metering pump 23, so that the aromatic dibasic acid and the aliphatic dibasic acid in the salt-forming kettle 19 are dissolved. The molar ratio of basic acid was stable at 55:45. After the composition of the above-mentioned salt solution is detect...

Embodiment 2

[0108] The prepolymer sprayed under reduced pressure in the flash reactor is dried in the spray tower by 130°C nitrogen circulation air containing dichloromethane vapor to obtain the prepolymer. The volume flow ratio of the extractant vapor to nitrogen is 1:80. Other steps and processes and implementation Example 1 is exactly the same, and the semi-aromatic polyamide product of about 12.2kg / h is finally obtained.

Embodiment 3

[0110] The prepolymer sprayed under reduced pressure in the flash reactor is dried in the spray tower by 100°C nitrogen circulation air containing chloroform vapor to obtain the prepolymer. The volume flow ratio of the extractant vapor to nitrogen is 1:40. Other steps and processes and implementation Example 1 is exactly the same, and the semi-aromatic polyamide product of about 11.8kg / h is finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com