Molten iron dross filtering structure in casting mold

A casting mold and filter structure technology, applied in the field of casting molds, can solve the problems of fragments rushing into castings, secondary slag, sand inclusions in castings, etc., and achieve the effects of improving position stability, improving impact resistance, and improving filtering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

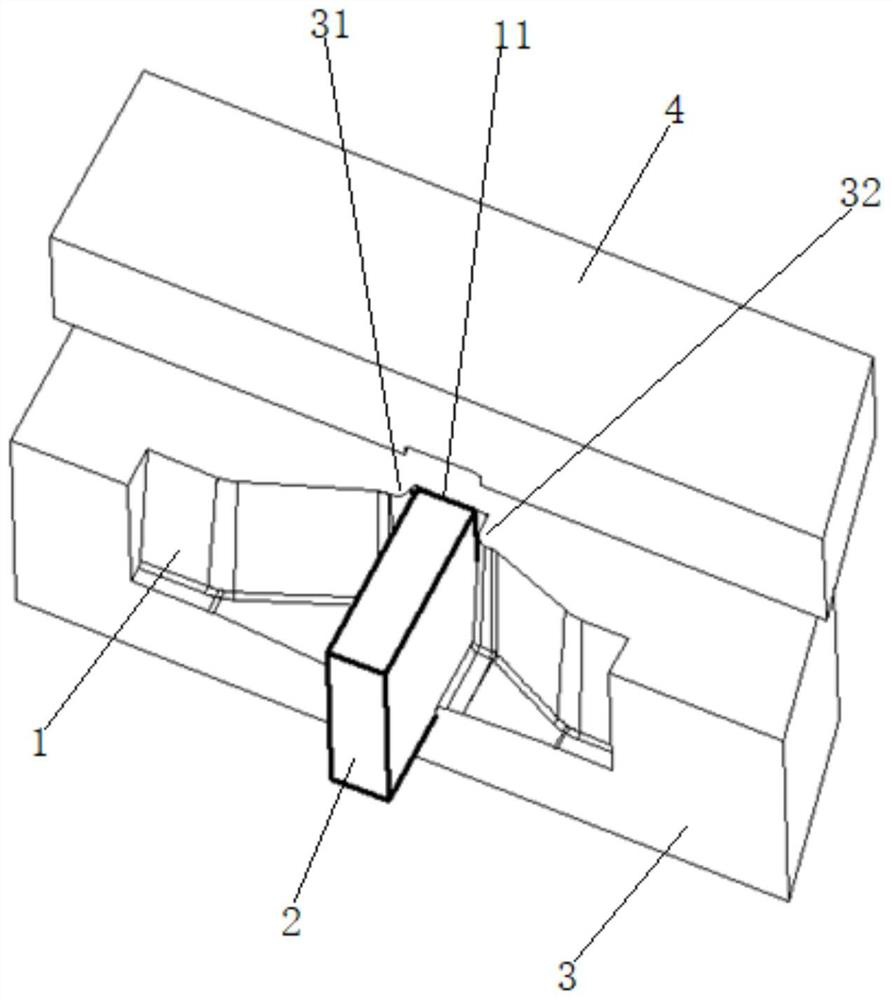

[0024] Please refer to Figure 1-Figure 5 , the present embodiment is a molten iron scum filter structure 100 in a casting mold, which includes a honeycomb filter block 2 arranged in the runner 1 and whose periphery is in contact with the inner wall surface of the runner 1. The runner 1 is formed by the lower mold 3 Surrounded by the profiling groove on the opposite surface of the upper mold 4, the upper surface of the honeycomb filter mesh block 2 protrudes from the upper surface of the lower mold 3 and the upper part is embedded in the lower surface of the upper mold 4. The width of the water inlet side is greater than the width of the water outlet side.

[0025] The runner 1 is provided with a closed groove 11 that defines the position of the honeycomb filter mesh block 2. The position of the honeycomb filter mesh block 2 is limited by the closed groove 11, and at the same time, the peripheral surface of the honeycomb filter mesh block 2 and the pouring Sealing of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com