Concentric permanent magnetic gear magnetism regulation ring device and production method thereof

A technology of concentric and magnetically adjustable rings, which is applied to permanent magnet clutches/brakes, electromechanical devices, electric brakes/clutches, etc., can solve the problem that the overall processing and assembly accuracy of magnetically adjustable rings cannot be guaranteed, and it is difficult to realize single-piece small batch production , It is difficult to realize integral processing and other problems, so as to achieve the effects of easy guarantee of processing accuracy, convenient processing and assembly, and high positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

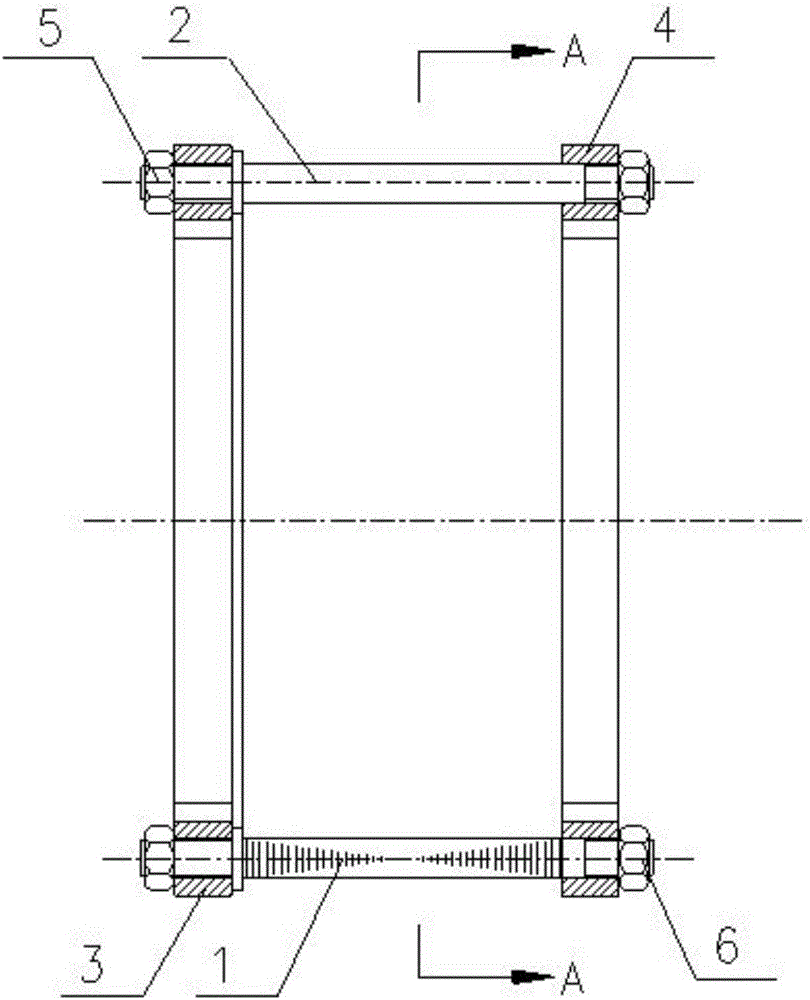

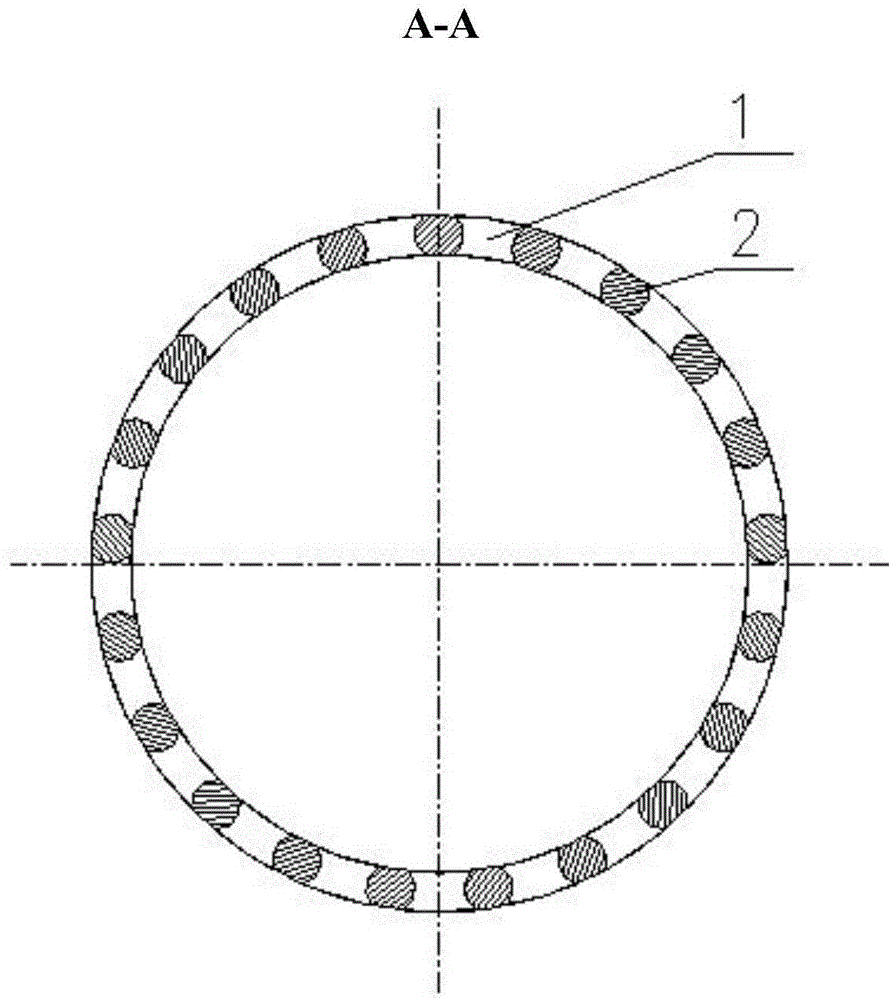

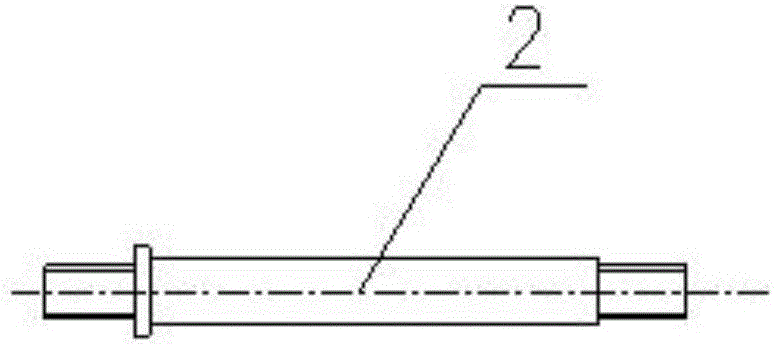

[0027] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-5 As shown, the concentric permanent magnet gear magnetic adjustment ring device includes a magnetic adjustment pole piece 1, a support pin 2, a left end ring 3, a right end ring 4, a left end nut 5 and a right end nut 6. The magnetic adjustment pole piece 1 passes through the support pin 2 , The left end nut 5 and the right end nut 6 are respectively connected with the left end ring 3 and the right end ring 4 as a whole.

[0028] Further, the magnetic adjustment pole piece 1 is in the shape of a cylinder, and a group of through holes are evenly distributed in the circumferential direction, and the left end ring 3 and the right end ring 4 are of the same ring structure, and a set of through holes are evenly distributed in the circumferential direction. hole, the position and quantity of the through hole are consistent with the position and quantity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com