Method for spraying anticorrosive paint on inner surface of ship seawater pipeline

A technology for anti-corrosion coatings and seawater pipes, applied in anti-corrosion coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as shortening the service life of coatings, discontinuous surfaces, and aggravating coating damage, and achieve uniformity and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

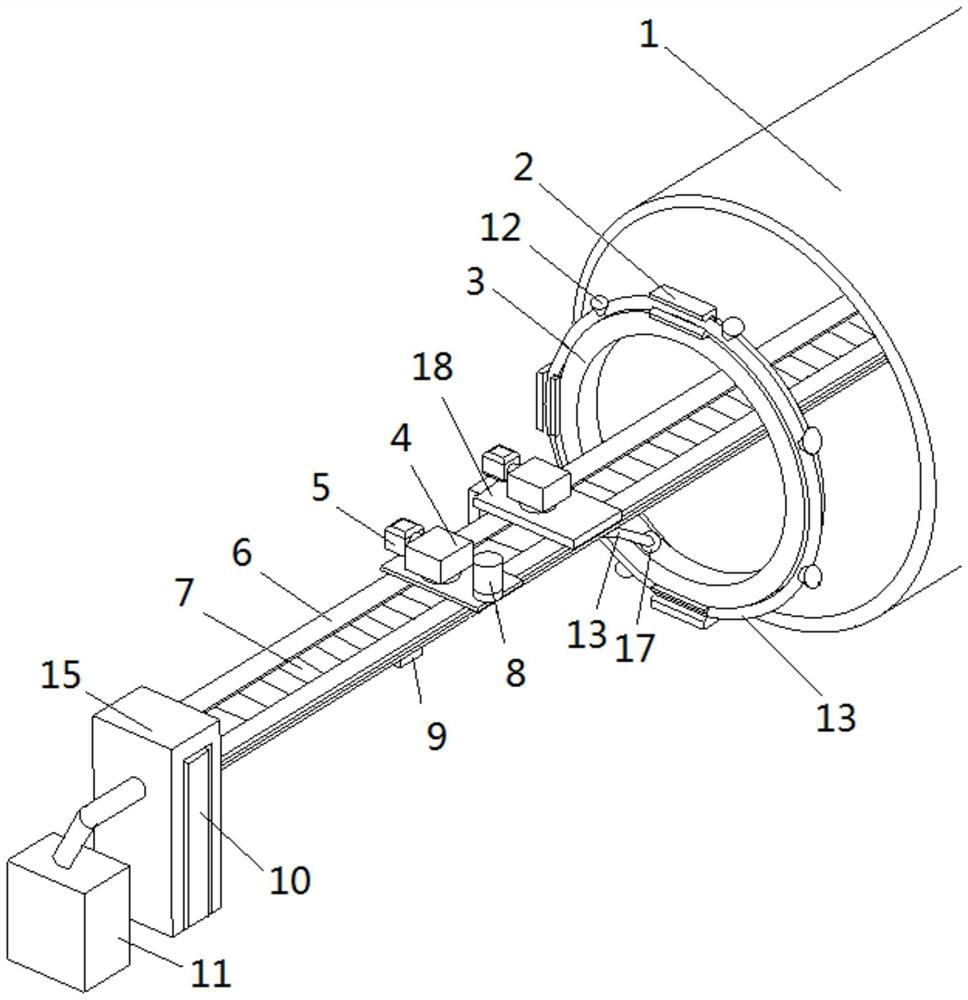

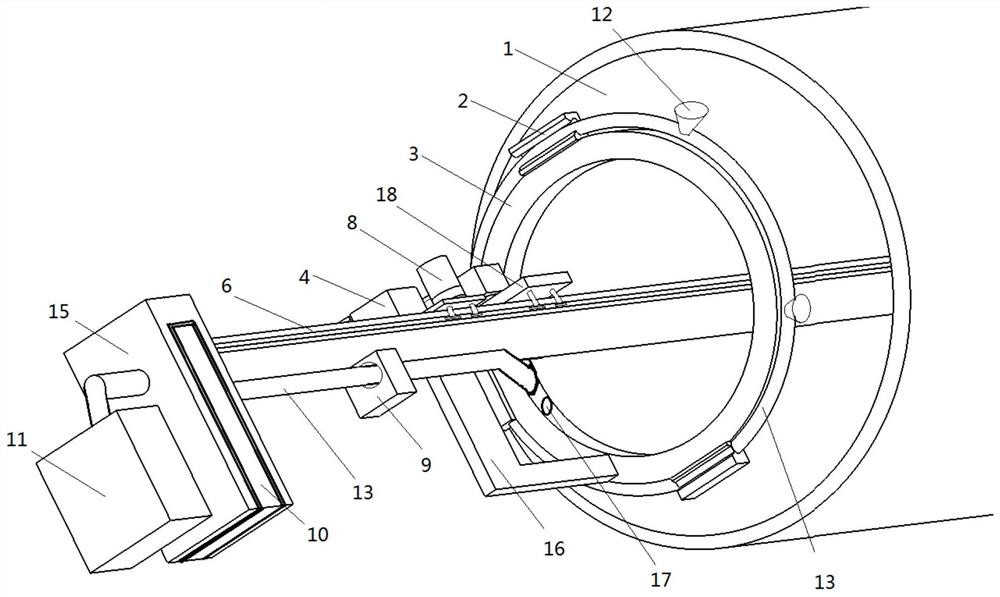

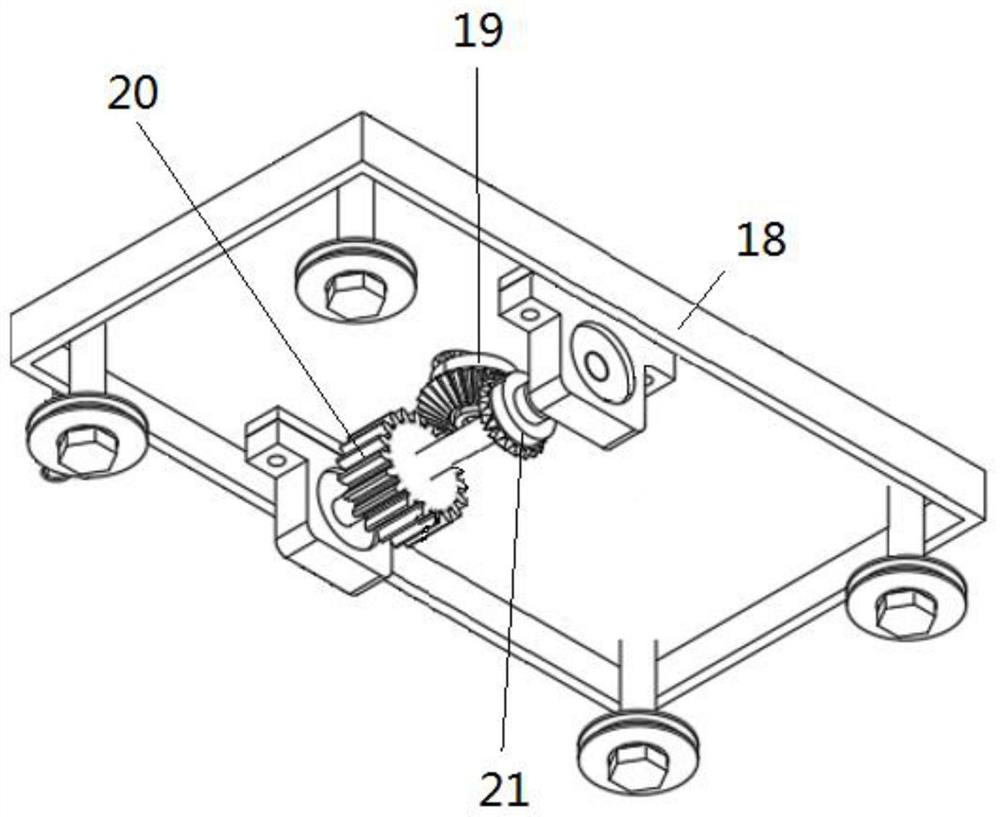

Image

Examples

Embodiment 1

[0037]First melt the anticorrosion coating powder into a liquid, and then spray it to the inner surface of the seawater pipeline; the anticorrosion coating powder is obtained by mixing epoxy resin coating and self-repairing microcapsules; the epoxy resin coating and self-repairing The weight ratio of the microcapsules is 100:3; the self-healing microcapsules include a core material and a wall material wrapping the core material, the core material is tung oil, and the wall material is sodium alginate solution and calcium chloride Calcium alginate, the reaction product of the solution, is mixed with sodium alginate solution, tung oil and OP-10, then placed in a tissue grinder and stirred at a speed of 6000r / min for 5 minutes to form oil-in-water emulsion droplets, which are obtained after standing still for defoaming Emulsion; drip the emulsion into the calcium chloride solution under a pressure of 0.43MPa, filter the microcapsules through a 400-mesh paper funnel, rinse off the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com