Electric vehicle IGBT health monitoring system based on fiber grating sensor

A health monitoring system and fiber grating technology, which is applied in the direction of single semiconductor device testing, instruments, measuring electricity, etc., can solve the problem that the junction temperature change of the IGBT chip cannot be reflected in time, the IGBT health monitoring is not involved, and the real IGBT chip can be accurately reflected. temperature rise etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

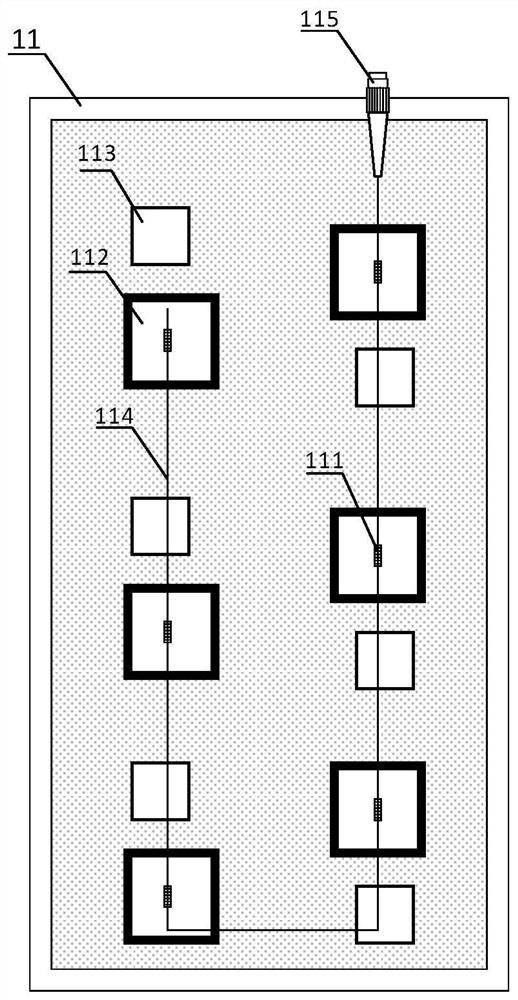

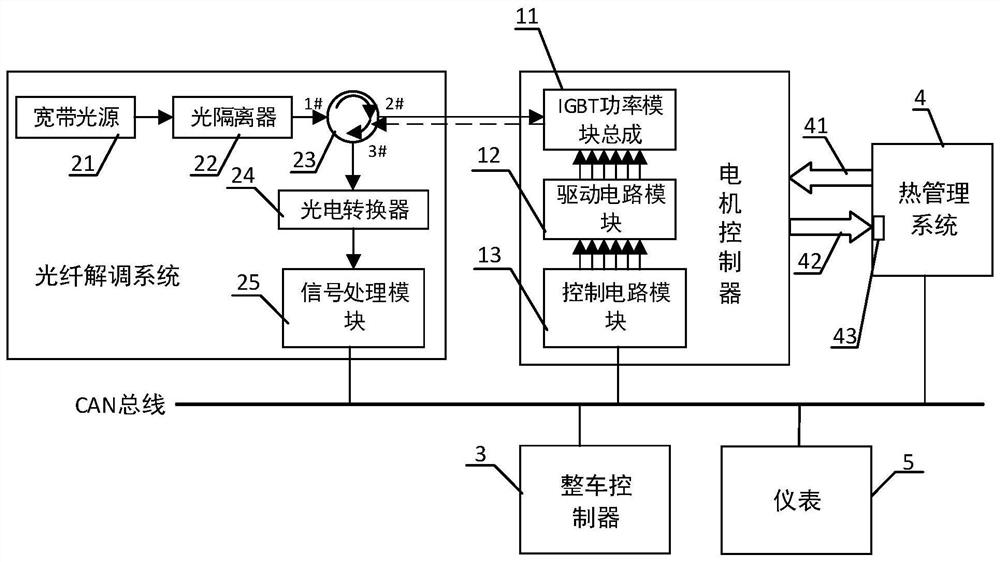

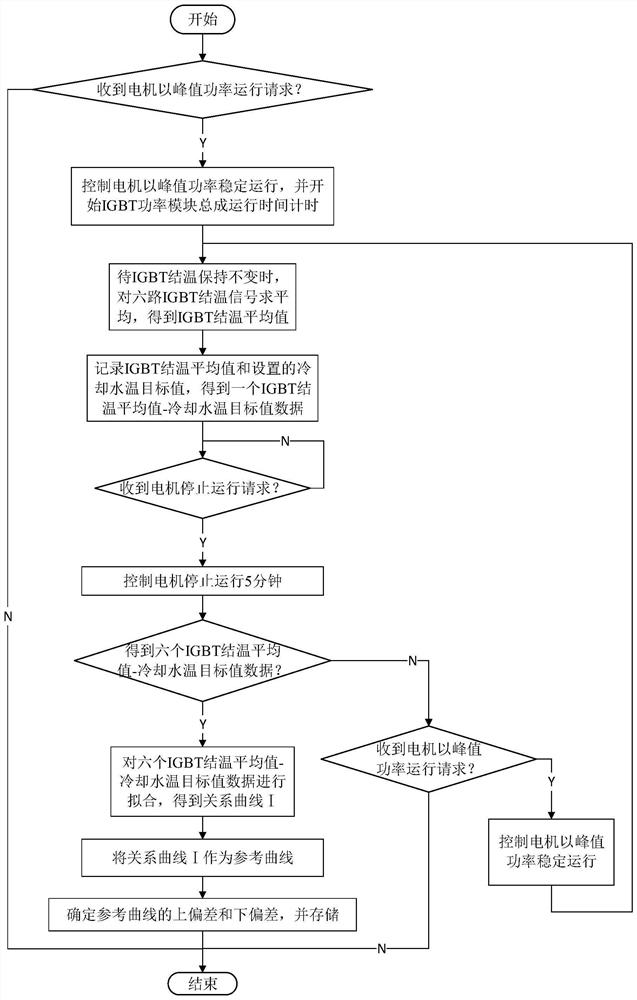

[0039] Such as figure 1 , figure 2 The shown IGBT health monitoring system for electric vehicles based on fiber grating sensors includes a motor controller, an optical fiber demodulation system, a vehicle controller 3 , a thermal management system 4 and an instrument 5 . The thermal management system 4 is connected to the cooling channel of the motor controller through the water inlet pipeline 41 and the water outlet pipeline 42. The thermal management system 4 has a temperature sensor 43 for detecting the temperature of the cooling water; the motor controller includes the IGBT power module assembly 11, and the IGBT power The drive circuit module 12 connected to the module assembly 11 and the control circuit module 13 connected to the drive circuit module 12; the optical fiber demodulation system includes a broadband light source 21, an optical isolator 22, an opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com