High-sensitivity fluorescent powder applied to temperature sensor and preparation method thereof

A temperature sensor and phosphor technology, applied in chemical instruments and methods, thermometers, thermometers with physical/chemical changes, etc., can solve the problems of low laser penetration and limited application, and achieve high thermal sensitivity and simple preparation process. , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

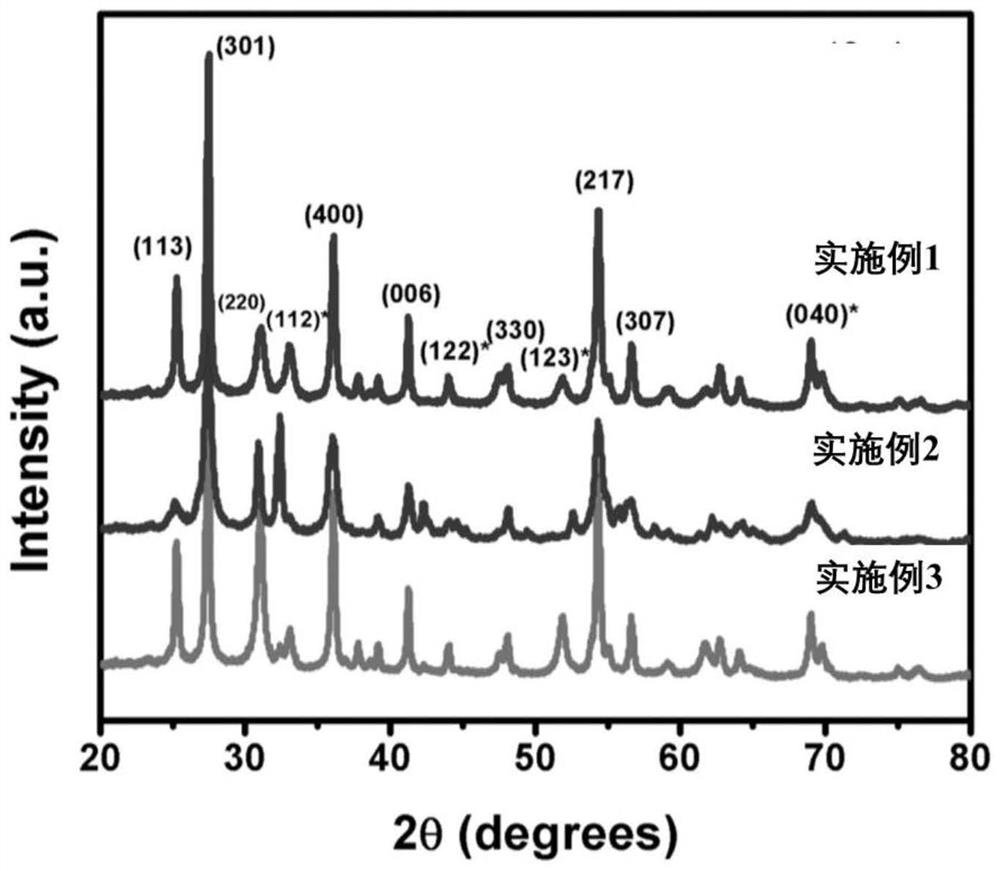

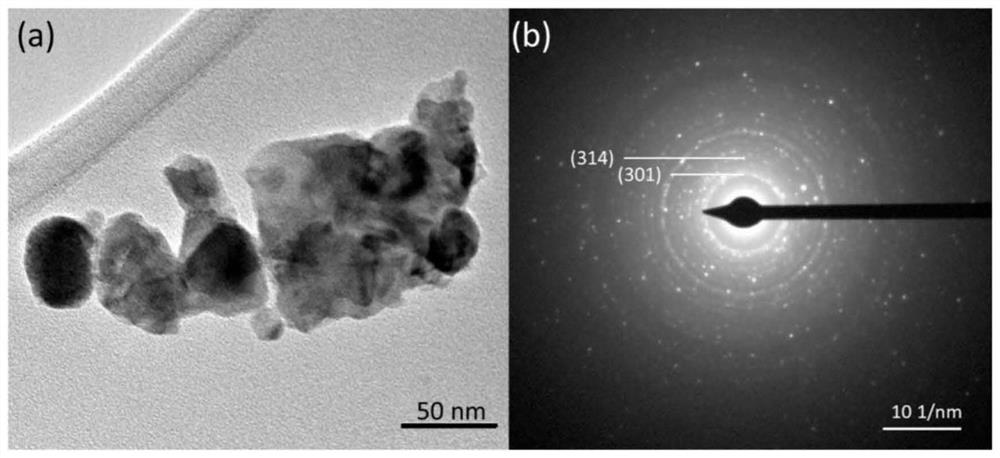

[0015] Example 1: CaTi 4 o 9 :0.005Er 3+ ,0.2Yb 3+

[0016] First, according to the stoichiometric ratio, the Er with a purity greater than 99.9% was weighed 2 o 3 , CaCl 2 and Yb 2 o 3 The raw materials were dissolved in a deionized aqueous solution of dilute nitric acid with a volume fraction of 8%, to prepare a solution with a metal ion concentration of 2 mol / L, and then heated the solution at 60° C. for 30 minutes. Then weigh the TiO that meets the stoichiometric ratio 2 , under magnetic stirring at 100rpm, the TiO 2 Soluble in absolute ethanol. After stirring at room temperature for about 30 min, the Ca(NO 3 ) 2 , Yb(NO 3 ) 3 , Er(NO 3 ) 3 The mixed solution of the above was slowly added dropwise to the ethanol solution of titanium dioxide. The temperature of the mixed solution was raised to 60° C., and the ethanol in the solution was heated and evaporated. Then the solution was kept at 80°C for about 10 h and then turned into a gel. Then the obtained g...

Embodiment 2

[0017] Example 2: CaTi 4 o 9 :0.1Er 3+ ,0.1Yb 3+

[0018] First, according to the stoichiometric ratio, the Er with a purity greater than 99.9% was weighed 2 o 3 , CaCl 2 and Yb 2 o 3 The raw material is dissolved in a deionized aqueous solution of dilute nitric acid with a volume fraction of 10%, to prepare a solution with a metal ion concentration of 0.5 mol / L, and then heat the solution at 80° C. for 10 minutes. Then weigh the TiO that meets the stoichiometric ratio 2 , under magnetic stirring at 200rpm, the TiO 2 Soluble in absolute ethanol. After stirring at room temperature for about 10 min, the Ca(NO 3 ) 2 , Yb(NO 3 ) 3 , Er(NO 3 ) 3 The mixed solution of the above was slowly added dropwise to the ethanol solution of titanium dioxide. The temperature of the mixed solution was raised to 80° C., and the ethanol in the solution was heated and evaporated. The solution was then kept at 70 °C for about 18 h and then turned into a gel. Then the obtained gel ...

Embodiment 3

[0019] Example 3: CaTi 4 o 9 :0.2Er 3+ ,0.005Yb 3+

[0020] First, according to the stoichiometric ratio, the Er with a purity greater than 99.9% was weighed 2 o 3 , CaCl 2 and Yb 2 o 3 The raw material is dissolved in a deionized aqueous solution of dilute nitric acid with a volume fraction of 9%, to prepare a solution with a metal ion concentration of 1 mol / L, and then heat the solution at 70° C. for 20 minutes. Then weigh the TiO that meets the stoichiometric ratio 2 , under magnetic stirring at 150rpm, the TiO 2 Soluble in absolute ethanol. After stirring at room temperature for about 20 min, the Ca(NO 3 ) 2 , Yb(NO 3 ) 3 , Er(NO 3 ) 3 The mixed solution of the above was slowly added dropwise to the ethanol solution of titanium dioxide. The temperature of the mixed solution was raised to 70° C., and the ethanol in the solution was heated and evaporated. The solution was then kept at 75 °C for about 12 h to become a gel. Then the obtained gel was calcined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com