A kind of temperature sensing rubber material and preparation method thereof

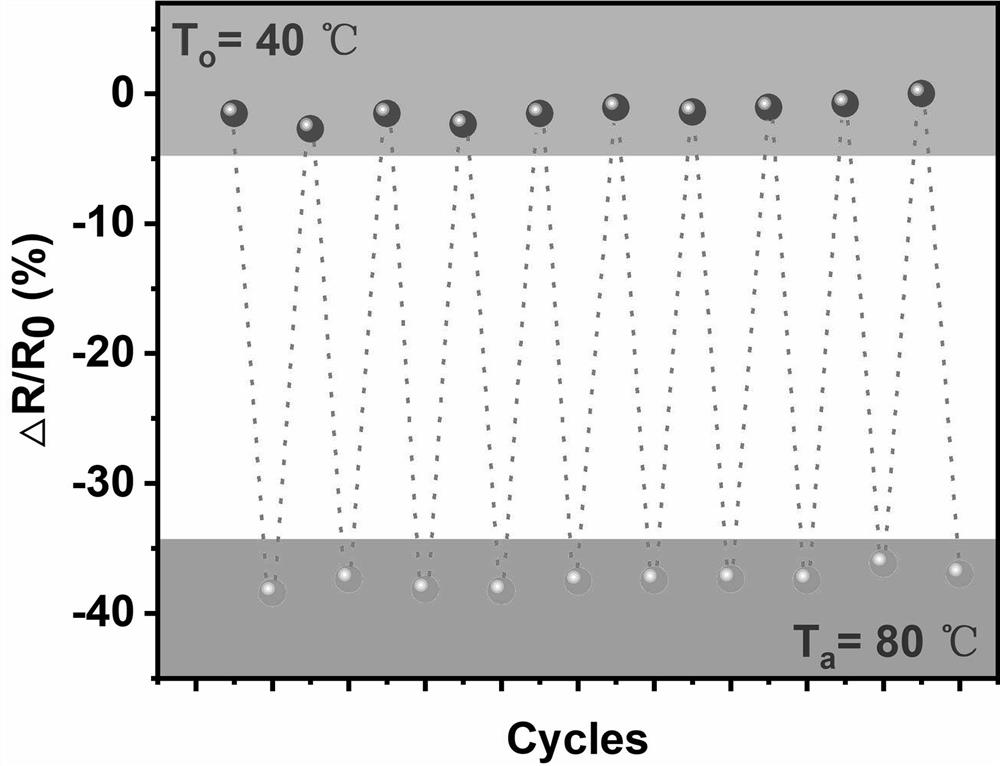

A rubber material and sensing technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of narrow sensing temperature range, low discernible resolution, complicated preparation process, etc., and achieve the sensing temperature The effect of wide range, high resolution and high thermal sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

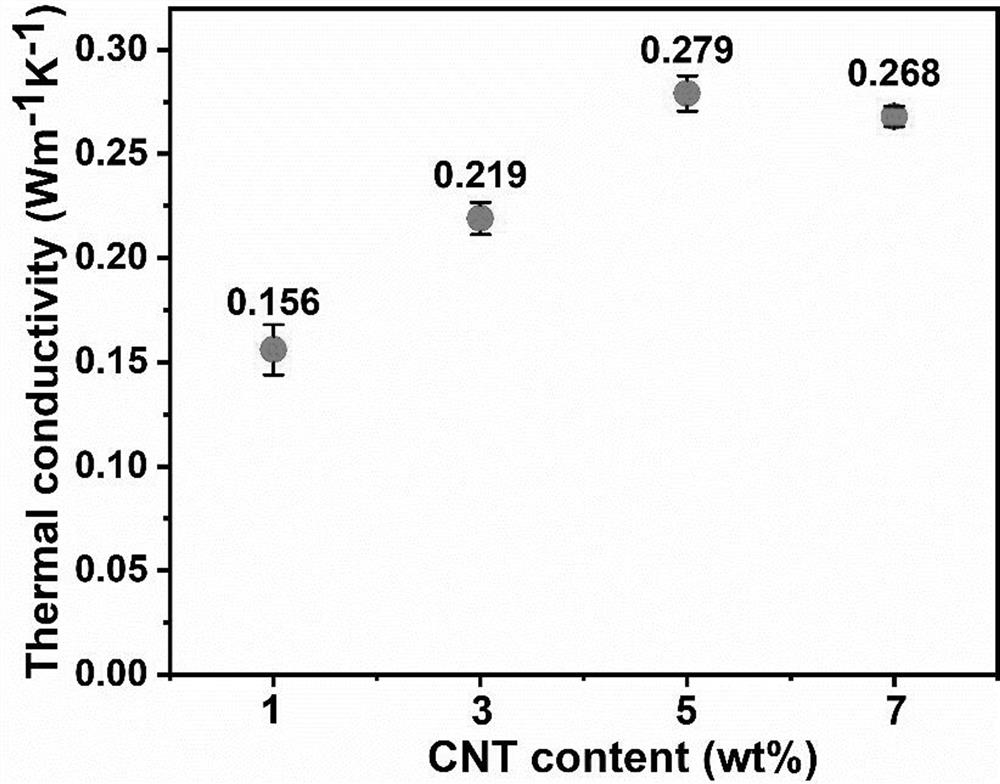

[0046] Mix 1.0 g of sericin powder with 50 mL of deionized water at room temperature, and then magnetically stir until the sericin is completely dissolved to obtain a sericin aqueous solution;

[0047] Grind 0.1 g of multi-walled carbon nanotubes in an agate mortar for 30 min, then slowly pour the ground carbon nanotubes into the above-mentioned completely dissolved sericin solution under magnetic stirring, stir for about 30 min, and then use a probe to sonicate The mixed solution of sericin and carbon nanotubes was ultrasonically treated by the instrument at 800W power for 10 min; Slowly add sericin and carbon nanotubes into the mixed solution of sericin and carbon nanotubes under mechanical stirring for 30 min; after mechanical stirring for 30 min, degassing for 5 min, followed by ultrasonic treatment, ultrasonic power is 600 W, ultrasonic The time is 30 minutes. After sonication for 30 min, the resulting mixture was poured into a polytetrafluoroethylene mold, dried at 40 °...

Embodiment 2

[0049] Mix 1.0 g of sericin powder with 50 mL of deionized water at room temperature, and then magnetically stir until the sericin is completely dissolved to obtain a sericin aqueous solution;

[0050] Grind 0.3 g of multi-walled carbon nanotubes in an agate mortar for 30 min, then slowly pour the ground carbon nanotubes into the above-mentioned completely dissolved sericin solution under magnetic stirring for about 30 min, and then use a probe to sonicate The mixed solution of sericin and carbon nanotubes was sonicated for 10 min under the power of 800 W. After ultrasonication for 10 min, 20.0 g of carboxylated styrene-butadiene rubber and 0.2 g of dicumyl peroxide were slowly added to the mixed solution of sericin and carbon nanotubes under mechanical stirring at a speed of 650 r / min, and the stirring time was 30 min. After mechanical stirring for 30 min, defoaming was carried out for 5 min, followed by ultrasonic treatment, the ultrasonic power was 600 W, and the ultrasoni...

Embodiment 3

[0052] At room temperature, 1.0 g of sericin powder was mixed with 50 mL of deionized water, and then magnetically stirred until the sericin was completely dissolved to obtain an aqueous solution of sericin.

[0053] Grind 0.5 g of multi-walled carbon nanotubes in an agate mortar for 30 min, then slowly pour the ground carbon nanotubes into the above-mentioned completely dissolved sericin solution under magnetic stirring for about 30 min, and then use a probe to sonicate The mixed solution of sericin and carbon nanotubes was sonicated for 10 min under the power of 800 W. After ultrasonication for 10 min, 20.0 g of carboxylated styrene-butadiene rubber and 0.2 g of dicumyl peroxide were slowly added to the mixed solution of sericin and carbon nanotubes under mechanical stirring at a speed of 650 r / min, and the stirring time was 30 min. After mechanical stirring for 30 min, defoaming was carried out for 5 min, followed by ultrasonic treatment, the ultrasonic power was 600 W, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com