Landscape water treatment purification material and preparation method thereof

A technology for purifying materials and landscape water, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as poor effect, achieve the effect of enhancing adsorption performance and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

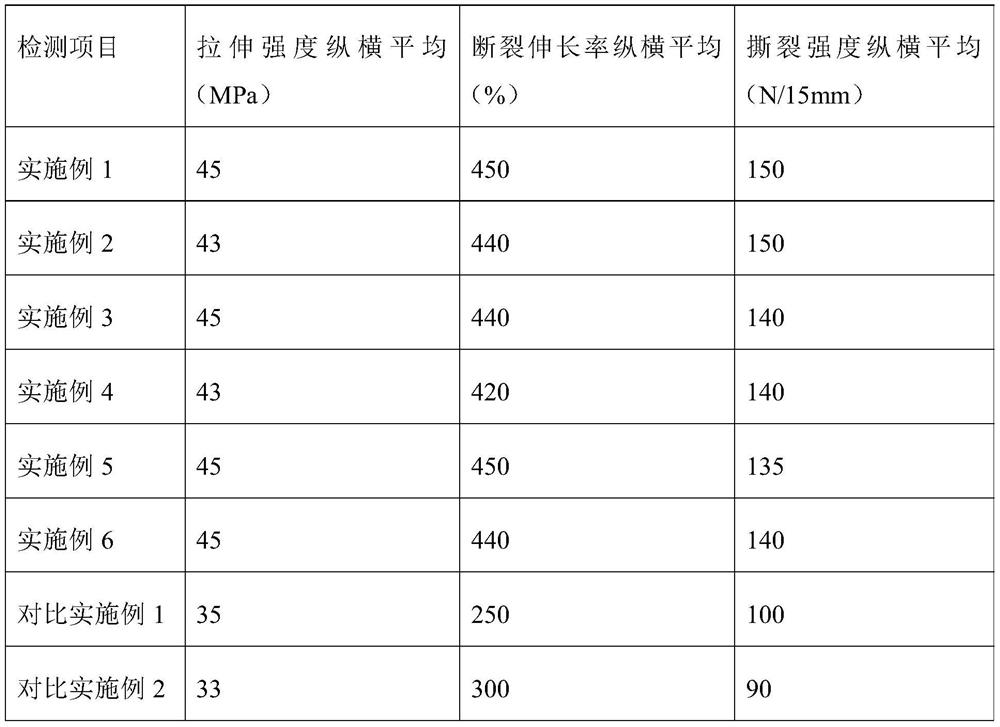

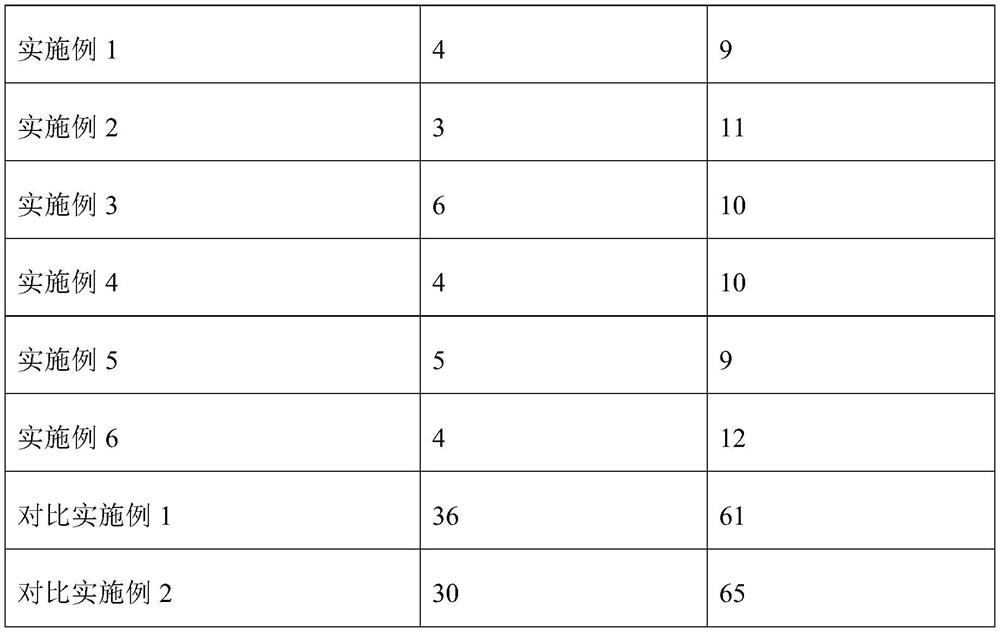

Examples

Embodiment 1

[0029] Preparation of polyurethane solution: Dissolve 3g of polyurethane in 15mL of N,N-dimethylamide solvent, heat in a water bath and reflux for 20min.

[0030] Preparation of poly-L-lactic acid solution: Dissolve 3g of poly-L-lactic acid in 25mL of glacial acetic acid and magnetically stir until the solution is uniform.

[0031] Take 10 g of aluminum oxyhydroxide and disperse it in 1200 mL of ethanol solution (concentration: 50%), and stir the solution evenly to obtain an aluminum oxyhydroxide solution. Under the protection of an inert gas, the potassium citrate was heated up to 1200°C at a heating rate of 2°C / min and calcined for 2 hours, then kept for 30 minutes, and cooled to room temperature to prepare carbon nanosheets. Then take 10 g of carbon nanosheets and add them to 600 mL of oxidizing acidic solution (a mixture of sulfuric acid, nitric acid, and hydrogen peroxide in a volume ratio of 0.3:0.8:0.2) to prepare porous carbon nanosheets through an oxidation reaction. ...

Embodiment 2

[0033] Preparation of polyurethane solution: Dissolve 4g of polyurethane in 15mL of N,N-dimethylamide solvent, heat in a water bath and reflux for 20 minutes.

[0034] Preparation of poly-L-lactic acid solution: Dissolve 3g of poly-L-lactic acid in 20mL of glacial acetic acid and magnetically stir until the solution is uniform.

[0035]Take 10 g of aluminum oxyhydroxide and disperse it into 1000 mL of ethanol solution (concentration: 50%), and stir the solution evenly to obtain an aluminum oxyhydroxide solution. Sodium citrate was heated up to 1000°C for 3 hours under the protection of inert gas at a heating rate of 3°C / min and calcined for 30 minutes, then cooled to room temperature to prepare carbon nanosheets. Then take 10 g of carbon nanosheets and add them to 600 mL of oxidizing acidic solution (a mixture of sulfuric acid, nitric acid, and hydrogen peroxide in a volume ratio of 0.5:0.5:0.5) to prepare porous carbon nanosheets through an oxidation reaction. Soak 5g of por...

Embodiment 3

[0037] Preparation of polyurethane solution: Dissolve 1 g of polyurethane in 10 mL of N,N-dimethylamide solvent, heat in a water bath and reflux for 20 minutes.

[0038] Preparation of poly-L-lactic acid solution: Dissolve 5g of poly-L-lactic acid in 20mL of glacial acetic acid and magnetically stir until the solution is uniform.

[0039] Take 10 g of aluminum oxyhydroxide and disperse it into 1200 mL of ethanol solution (concentration: 75%), and stir the solution evenly to obtain an aluminum oxyhydroxide solution. Under the protection of an inert gas, the potassium citrate was heated to 1200° C. for 1 hour at a heating rate of 3° C. / min and calcined for 30 minutes, then cooled to room temperature to prepare carbon nanosheets. Then take 10 g of carbon nanosheets and add them to 800 mL of oxidizing acidic solution (a mixture of sulfuric acid, nitric acid, and hydrogen peroxide at a volume ratio of 0.5:1:0.5) to prepare porous carbon nanosheets through an oxidation reaction. So...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com