Flexible neodymium-iron-boron magnet as well as preparation method and application thereof

A NdFeB magnet technology, applied in the field of flexible NdFeB magnets and its preparation, can solve the problems of magnetic powder falling off, easy to break, poor toughness, etc., and achieve the effects of reducing magnetic performance, easy orientation, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055]The present invention provides a method of preparing a flexible NdFe boron magnet, comprising the steps of:

[0056]1) Sie grading of NdFeB magnetic powder with a fluid spiral screening of 180.

[0057]2) Take the 180 mesh of NdFe-boron magnetic powder in step 1) to the closed stirring tank, and an aluminate coupling agent is added, and stirred at 50 to 60 Hz frequencies 30 to 35 min.

[0058]3) Take step 2) Treatment of NdFeB magnetic powder, together with rubber and excipients, put into the unfaming machine under circulation of inert gas (preferably nitrogen) protection, each raw material is 85% ~ 95 of magnetic powder 85% ~ 95 %, Rubber 2.5% ~ 9%, excipients 2.5% ~ 6%. The penetration time is about 12 to 15 min, and the penetration temperature is 120 to 130 ° C.

[0059]4) Take step 3) The medium-sidedly refined material is opened for 2 to 3 min in the preheated mold (60 ~ 80 ° C), and the material on the open mill is flattened in the ventilation of 3 to 4 h.

[0060]5) Take the material ...

Embodiment 1

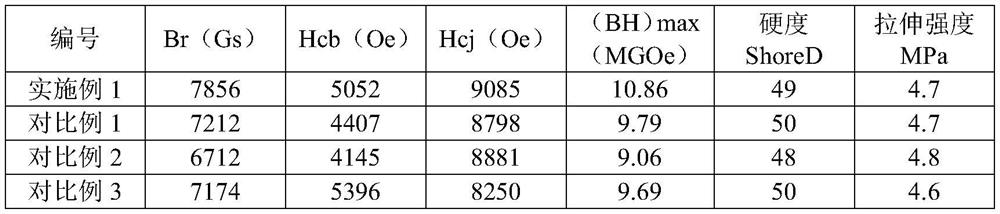

[0066]A flexible NdFeB magnet, the composition of the raw material is shown in the following table:

[0067]Table 1. Flexible NdFeB magnets

[0068]

[0069]The method of preparing the flexible NdFeB magnet comprises the steps of:

[0070]1) Sie grading of NdFeB magnetic powder with a fluid spiral screening of 180.

[0071]2) Take 180 目 目 旋,, 入 剂 剂 剂 剂 剂 剂 剂 剂 剂 剂 剂 偶 剂 偶 剂 剂 剂 剂 剂 剂 剂 剂 剂

[0072]3) Take the step 2) Treatment of NdFeB magnetic powder, with rubber and remaining excipients to put into the unfaming machine under a circulation of nitrogen protection. The penetration time is about 13 min, and the high refining temperature is 125 ° C.

[0073]4) Repairing the refined material is opened for 2.5 min on the open mill that has been preheated to 65 ° C, and the material on the open mill is flattened in the ventilation of 3 hours.

[0074]5) Take step 4) After the material is re-extracting it to 90 ° C, it is broken with a crusher, and then the crushing pellets are pulled into 2.5 mm sheet.

[0075]6) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com