Method for preparing chopped carbon fiber reinforced amorphous composite material and a device thereof

A technology of amorphous composite material and chopped carbon fiber, which is applied in the field of preparation of chopped carbon fiber reinforced amorphous composite material, can solve the problems of fast cooling speed, poor wettability, low cooling rate, etc., and achieves small negative damage and improved Wetting property, effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

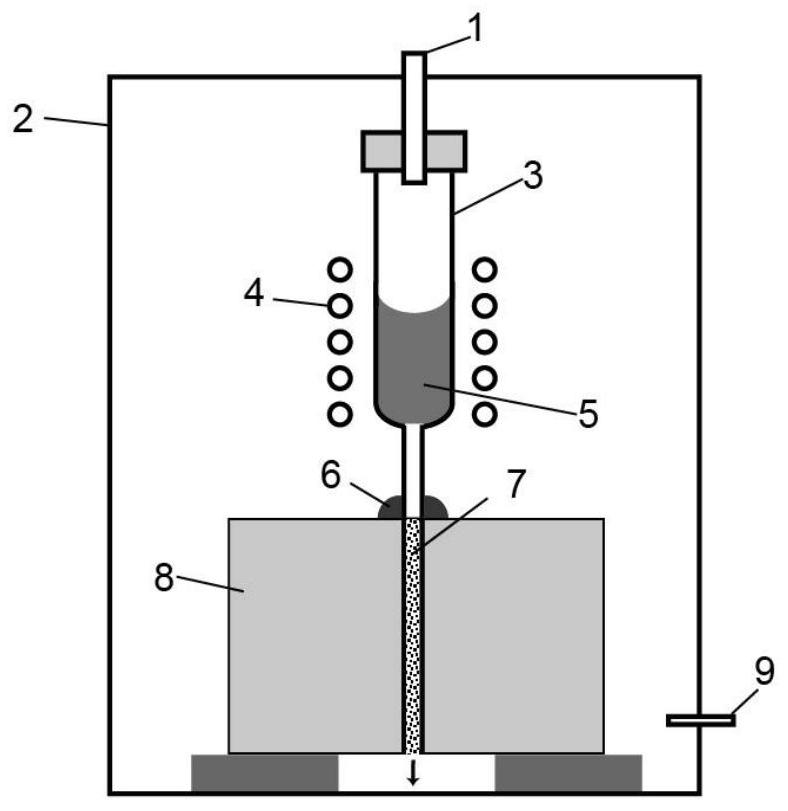

[0043] figure 1The illustrated embodiment shows that the components of the device used in the preparation method of the chopped carbon fiber reinforced amorphous composite material include: an air inlet 1, a closed high vacuum induction heating spray casting furnace body 2, a thick tube with a A quartz tube with a diameter of 0.5 mm to 2 mm nozzle 3, a water-cooled induction heating coil 4, high-temperature cement 6, a split copper mold with an inner cavity diameter of 2 mm to 30 mm 8, and a closed furnace body 2. The outlet is connected to the valve 9 of the vacuum system; the connection mode of each component of the device is: the split copper mold 8 is placed in the center of the closed furnace body 2, and the water-cooled induction heating coil 4 is arranged on the thick tube of the quartz tube 3 Around the part, the spout part of the quartz tube 3 is in contact with the inner cavity of the split copper mold 8 from the top of the split copper mold 8 and is sealed with high...

Embodiment 1

[0051] The components of the device used in the preparation method of chopped carbon fiber reinforced amorphous composite materials include: air inlet 1, a closed high vacuum induction heating spray casting furnace body 2, and a thick tube with a diameter of 0.5mm~ Quartz tube with 2mm spout 3, water-cooled induction heating coil 4, high-temperature cement 6, split copper mold with an inner cavity diameter of 2mm to 30mm 8, a closed furnace body 2 with a vacuum system connected to the gas outlet on the lower side Valve 9; the connection mode of each component of the device is: the split copper mold 8 is placed in the central position of the closed body of furnace 2, the water-cooled induction heating coil 4 is arranged around the thick tube part of the quartz tube 3, and the quartz tube The spout part of 3 is in contact with the inner cavity of the split copper mold 8 from the top of the split copper mold 8 and is sealed with high temperature cement 6 to avoid air leakage. The ...

Embodiment 2

[0056] The first step, chopped carbon fiber electroless plating:

[0057] Commercial T800 carbon fiber is used for shearing, and then sieved with a 400-mesh sieve, and the chopped carbon fiber under the sieve is taken to obtain a chopped carbon fiber with a length of 30 μm, and the chopped carbon fiber is subjected to electroless copper plating. The process includes: Pretreatment →Sensitization, activation→reduction→plating, in which the pretreatment uses the burning method and organic solvent immersion, the specific process is 1h in a heating furnace at 420°C, then soaked in acetone for 1h, then ultrasonically cleaned with alcohol for 15min, and dried Then use concentrated nitric acid to soak for 1 hour to roughen, then rinse repeatedly with clean water until all residual nitric acid is removed, and then dehydrate and dry with alcohol; for sensitization and activation, put the roughened carbon fiber into the sensitization-activation solution and mechanically stir for 15 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com