Ultra-high-performance water-based mirror surface two-component varnish and preparation method thereof

An ultra-high performance, two-component technology, used in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problem of high hardness and fullness, paint film gloss, fullness and hardness are not ideal, gloss Advanced problems, to achieve high gloss fullness, high fullness, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

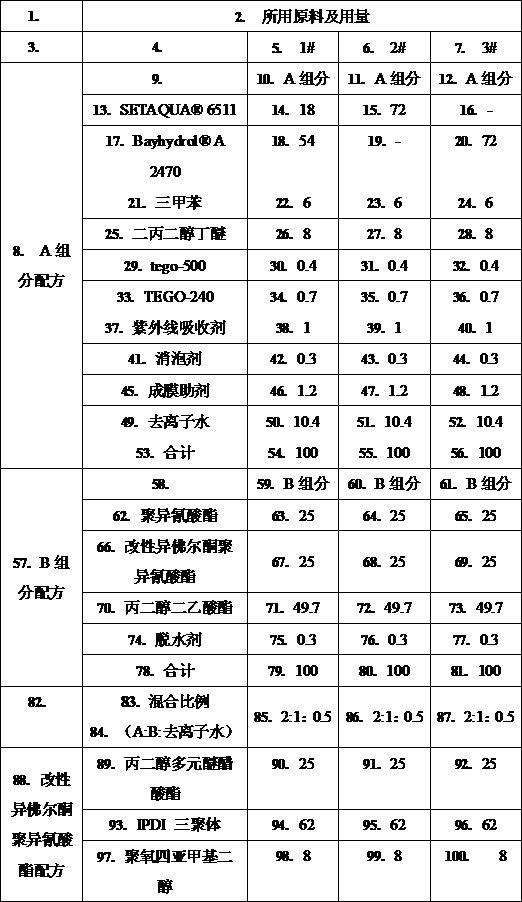

Embodiment 1

[0022] A super high performance aqueous mirror double-component varnish, preparation method:

[0023] Preparation of a component:

[0024] (1) Initiate aqueous dispersion resin, deionized water, deionized water, stirred at 300-600 rpm, stirred for 5-10 minutes;

[0025] (2) Add a wetting agent, a leveling agent, an ultraviolet absorber, an antifoaming agent, 300-600 rpm, and stir for 5-10 minutes;

[0026] (3) The formation of triphenyl, DPNB, film forming auxiliary agent was added to (2), and stirred at 300-600 rpm, stirred for 5-10 minutes to obtain a component.

[0027] B component preparation:

[0028] (4) In the sealed container, it is placed in the closed container, respectively, the amount of water dispersion type polyisocyanate, aqueous dispersion type modified isopolyoids, propylene glycol dikyl acetate and dehydrated agent, 300-600 rpm, stirred after 20min The B component, wherein the preparation method of the polyisocyanate in the B component is: in three flasks equippe...

Embodiment 2

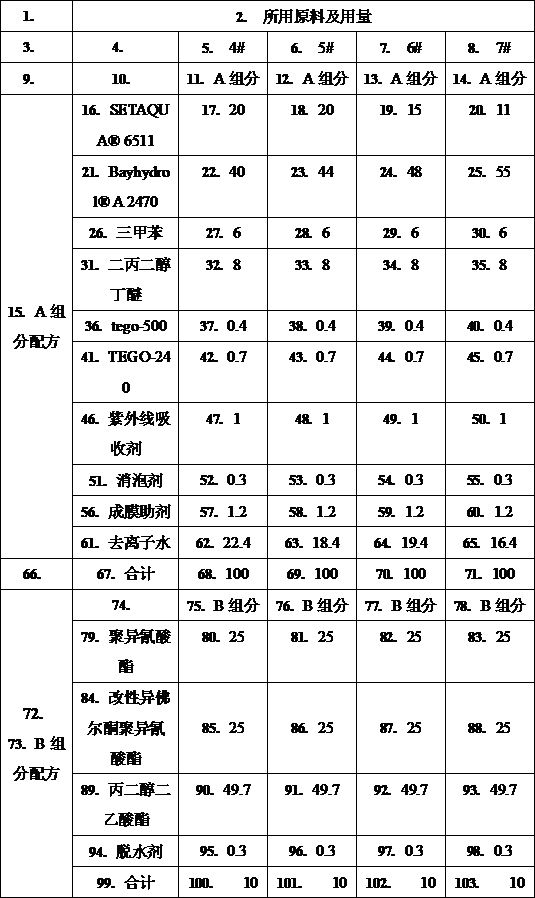

[0036] Example 2 is an experiment in the case of varying acrylic acid and polyurethane resin, and the formulation number is 4 #, 5 #, 6 #, 7 # (Table 3), according to the preparation process of Example 1. Preparation of color lacquer and its process to prepare a paint film. Table 4 is the paint film performance detection of Example 2, and the lacquer film specular effect of the curing agent system is very good, the gloss and fullness of the fullness are relatively high, 5 # and 6 # square water resistant, buttone resistant performance, 4 #Electronics with 7 # squares. This is because the hydroxy polyurethane dispersion is combined with a hydroxyacrylate dispersion. The ratio of the two is 1: 2.5-4, and the performance advantage is obvious. In the case of satisfying high gloss, the flexibility, Narotyne The performance of ketone, water resistant, etc., in line with the application of bus passenger cars and rail transportation facilities.

[0037] Table 3 Example 2 Details of specif...

Embodiment 3

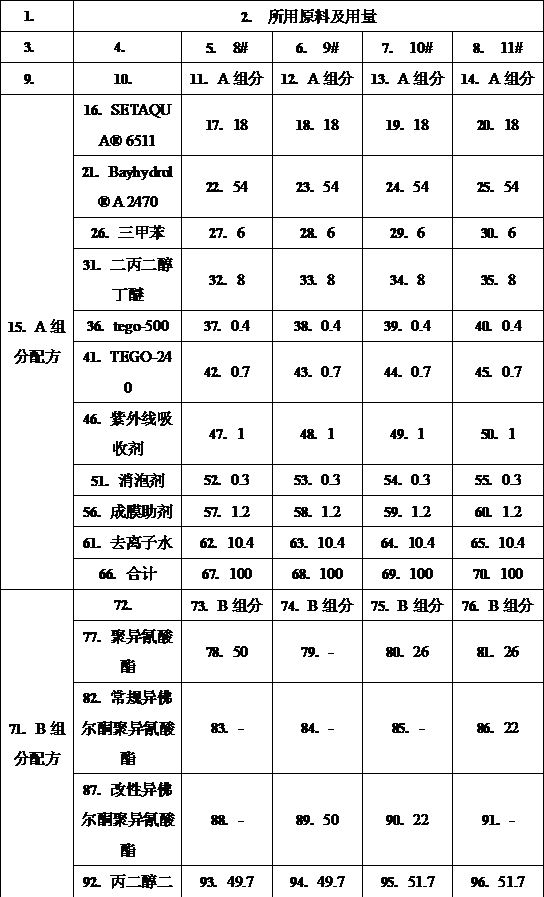

[0042]Example 3 is an experiment in the case where other materials are not changed, and the formulation is 8 #, 9 #, 10 #, 11 # (Table 5), prepared according to the preparation process of Example 1. Paint film is prepared in the process of paint and its process. Table 6 is the performance detection of the paint film in Example 3, known from the table, under the fixation of the resin system, the species of the curing agent on the gloss, fullness, water resistant and Narbone test of the paint film, and the formulation The modified isophorone polyisocyanate uses a special process, which is grafted, involved in acrylic acid and polyurethane, which plays an important role in the performance of the paint film, combined with polyisocyanate, and achieves gloss to reach 97. 60 °), completely realize the mirror effect, the fullness can reach 97 or more, hardness Implement H-class; and use conventional isocyanate or only polyisocyanate or modified isoplastin polyisocyanate paint film propert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com