Device for preparing graphene by taking asphalt as raw material

A graphene and raw material technology, applied in the field of graphene device preparation, can solve the problems of long production time, easy occurrence of dizziness, headache or cough, human health hazards and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

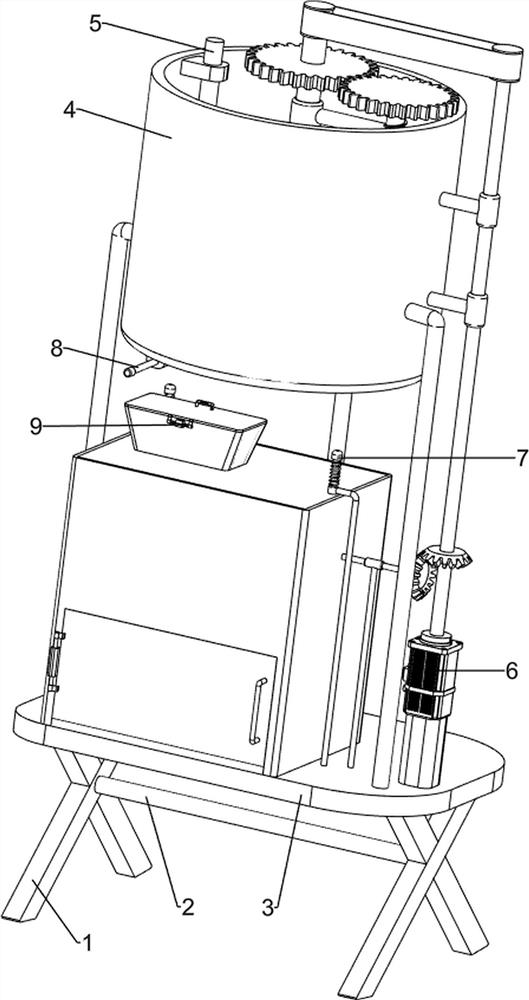

[0030] A device for preparing graphene with pitch as raw material, such as figure 1 As shown, the first fixed mount 1, the second fixed mount 2, the fixed plate 3, the stirring mechanism 4 and the mixing mechanism 5 are included, and the second fixed mount 2 is arranged between the first fixed mounts 1 on the left and right sides. The first fixed frame 1 is provided with a fixed plate 3, the top of the fixed plate 3 is provided with a stirring mechanism 4, and the inside of the stirring mechanism 4 is provided with a mixing mechanism 5.

[0031] When people need to prepare graphene with asphalt, they can use this kind of asphalt as raw material to prepare graphene device. First, people need to add some substances into the viscous liquid asphalt, and pour the asphalt into the 4 parts of the stirring mechanism, and then Manually rotate the 4 parts of the mixing mechanism to make the 5 parts of the mixing mechanism rotate, which can make the asphalt mix more evenly and will not s...

Embodiment 2

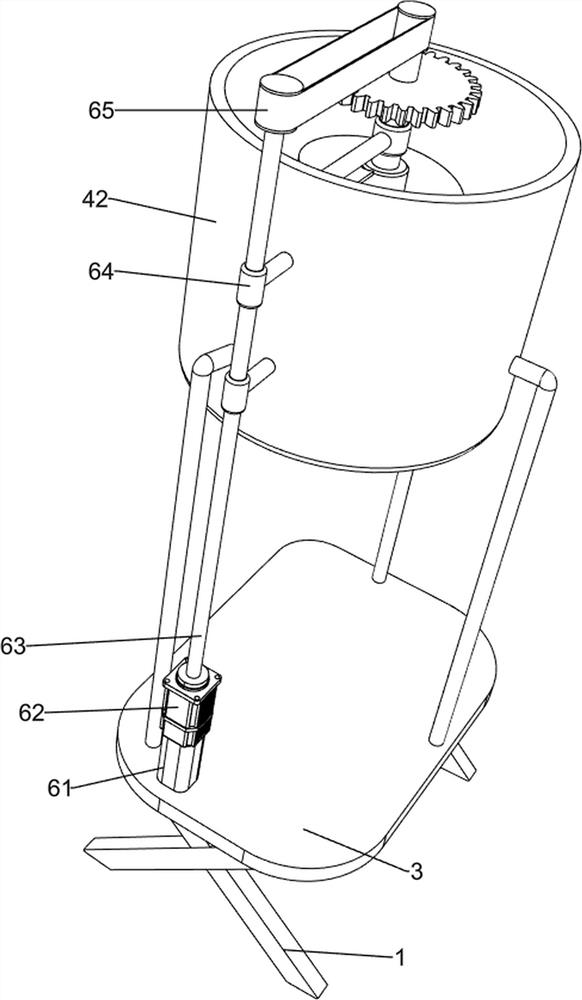

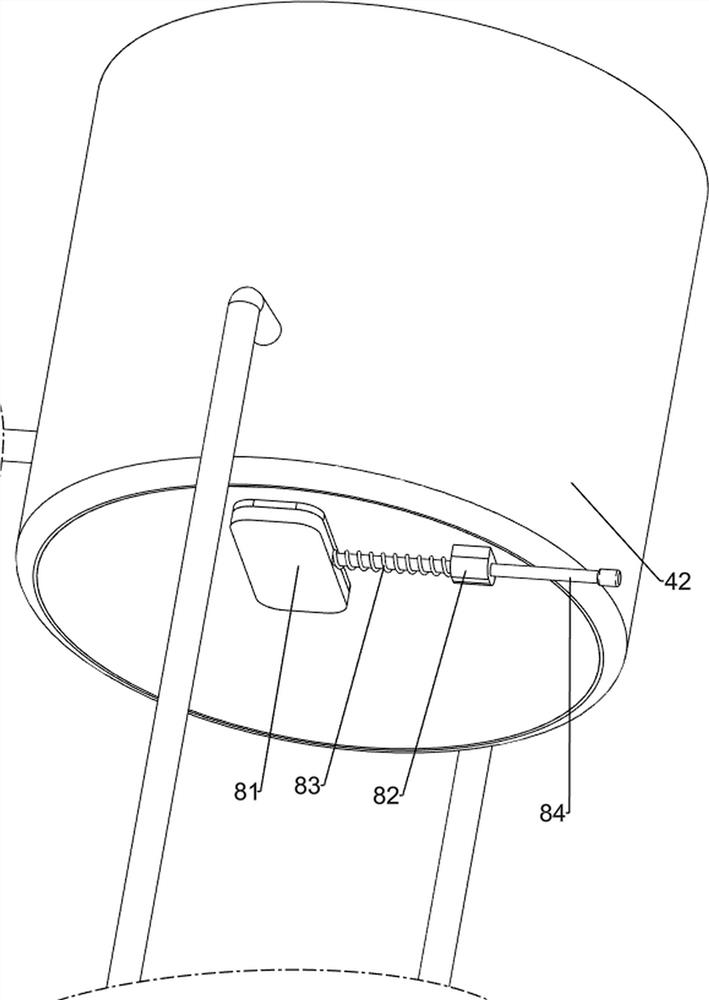

[0033] On the basis of Example 1, such as Figure 2-Figure 8 As shown, the stirring mechanism 4 includes a third fixed mount 41, a feeding bucket 42, a fourth fixed mount 43, a first stirring plate 44, a screw rod 45 and a first rotating shaft 46, and the top of the fixed plate 3 three sides is provided with three The third fixed mount 41, three third fixed mounts 41 are provided with a discharge barrel 42, the upper right side inside the discharge barrel 42 is provided with a fourth fixed mount 43, and the left side of the fourth fixed mount 43 is rotated to be provided with a first Rotating shaft 46, the bottom of the first rotating shaft 46 is provided with a screw rod 45, and the bottom of the screw rod 45 is provided with a first stirring plate 44.

[0034] People pour the liquid asphalt with substances into the discharge barrel 42, and then manually rotate the first rotating shaft 46, thereby driving the screw rod 45 to rotate, and then driving the first stirring plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com