AGV unboxing and disinfecting stacking vehicle

A palletizing truck and palletizing technology, which is applied in the field of port loading and unloading artificial intelligence robots, can solve the problem of infection of loading and unloading workers, achieve the effect of reducing economic pressure and social pressure, and isolating infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

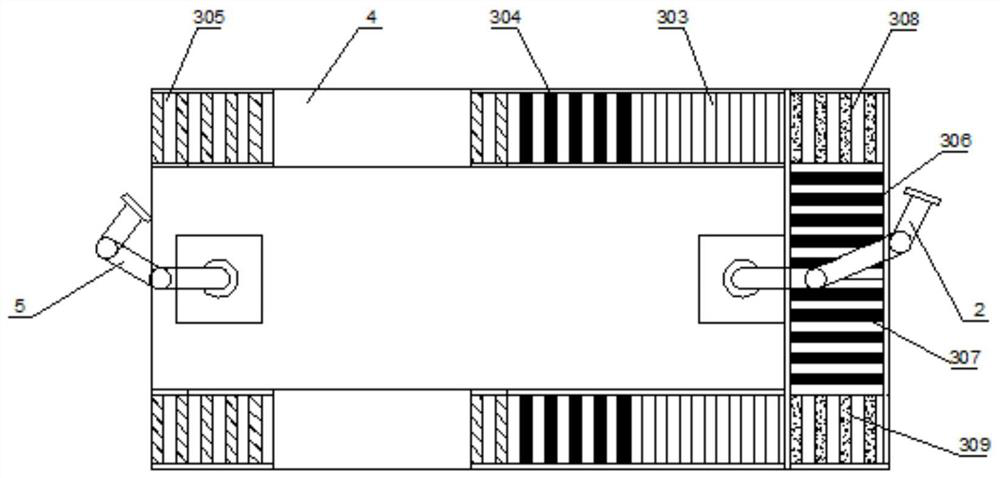

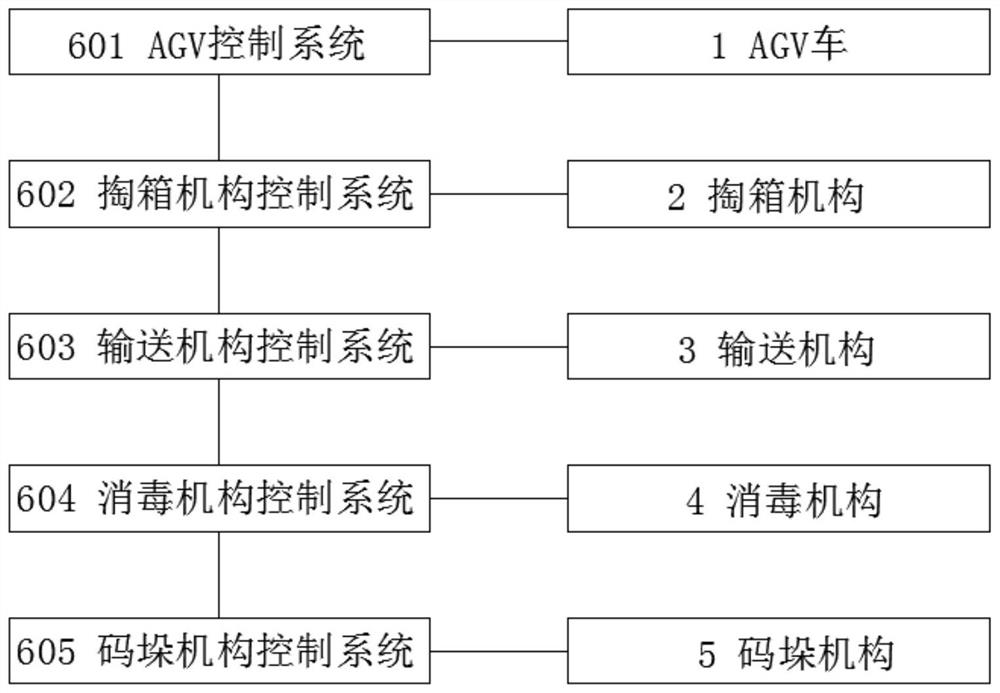

[0020] A kind of AGV unboxing and disinfection palletizing vehicle involved in this embodiment includes an AGV vehicle 1, an unpacking mechanism 2, a conveying mechanism 3, a disinfection mechanism 4, a palletizing mechanism 5 and a control platform 6, and the AGV vehicle 1 is used to implement and refrigerate The automatic docking and stepping of the container, the unboxing mechanism 2 fixes the middle part of the front end of the AGV car 1, and is used to take out the goods in the refrigerated container and place it on the conveying mechanism 3, and the conveying mechanism is fixed on the lifting platform and the AGV car at the front end of the AGV car 1 1 on both sides, used to transport the goods from the working area of the unpacking mechanism 2 to the working area of the disinfection mechanism 4. The disinfection mechanism 4 is fixed on the rear ends of both sides of the AGV vehicle 1. The front end of the conveyor at the bottom of the disinfection mechanism 4 is conne...

Embodiment 2

[0028] Present embodiment is all identical with embodiment 1 except AGV car 1 other, and AGV car 1 comprises AGV car chassis 101, driving wheel 102, driven wheel 103, steering wheel drive unit (not shown in the figure), intelligent sensor 104 and rechargeable battery (not shown in the figure), two driving wheels 102 and two driven wheels 103 are symmetrically fixed left and right under the AGV chassis 101, and the driving wheel 102 is connected with the steering wheel drive unit, and realizes advancing, retreating, Travel left and right to reach the refrigerated container loading and unloading station, along the direction of travel of the AGV car 1, fixedly install smart sensors 104 around the chassis 101 of the AGV car, collect and analyze image data in the peripheral field of view in real time to determine the distance from the front object, and It can be used to ensure that the distance between the AGV vehicle and the cargo surface at the front end of the refrigerated contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com