Robot double-wire welding gun cleaning station

A robot and double-wire technology, applied to welding accessories, etc., can solve the problems of welding spatter, dead angle of cleaning gun, poor spatter removal effect, etc., and achieve the effect of improving welding quality and efficiency and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

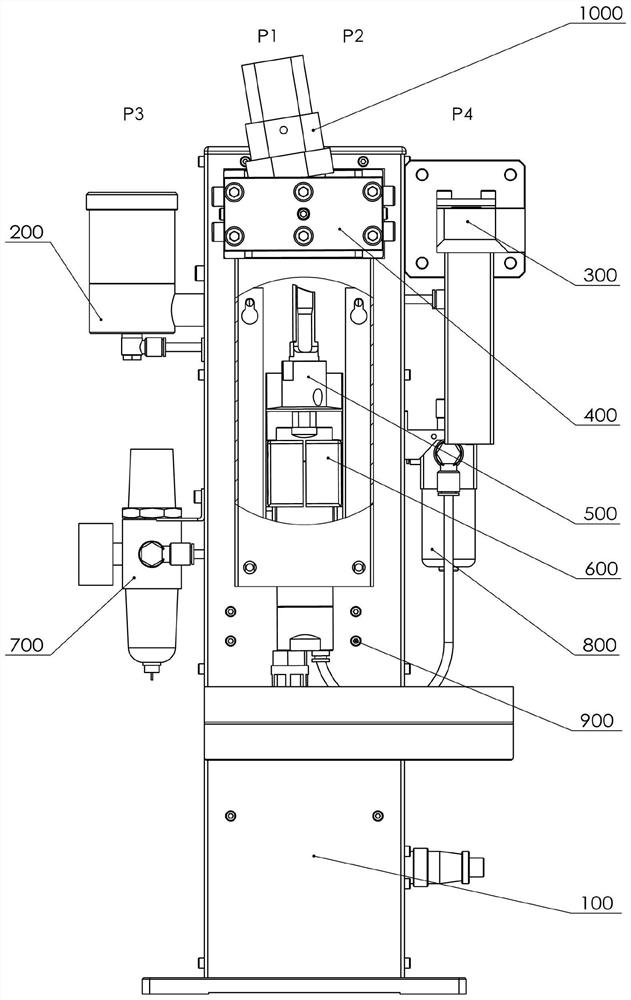

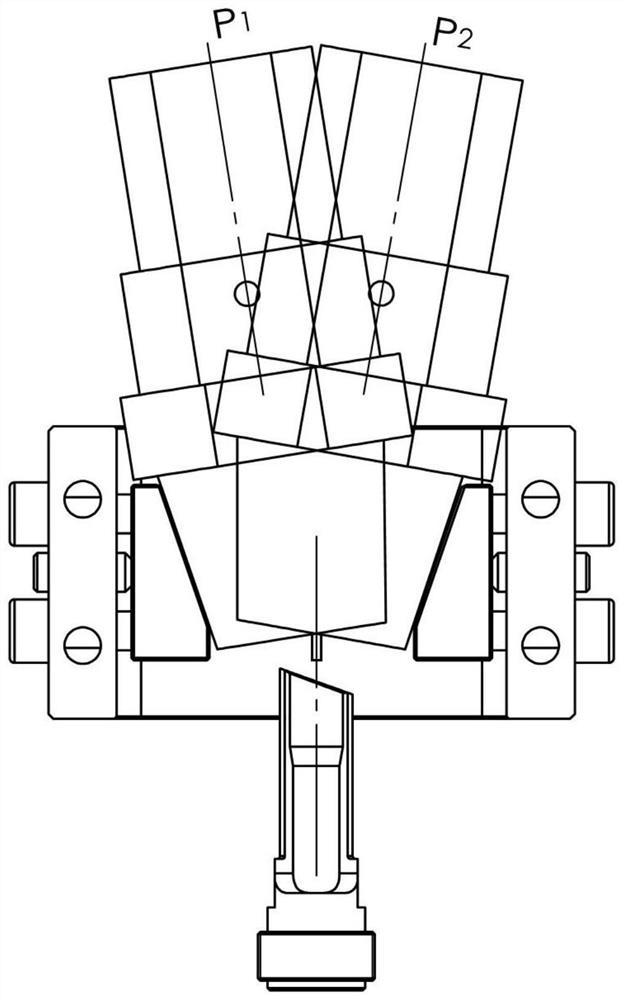

[0021] Such as figure 1 and figure 2 As shown, a robot twin-wire welding torch clearing station includes a fuselage 100, an oil spray device 200 and a wire cutting device 300. The fuselage 100 is a box structure, and an oil sprayer is fixedly installed above the side wall of the fuselage 100. The mist device 200 is provided with an air filter device 700 below the oil spray device 200, and the air filter device 700 is connected to the fuselage 100 by bolts. A lubricator 800 is arranged below the wire cutting device 300 .

[0022] Such as figure 1 As shown, a reamer driving device 500 is fixedly installed inside the fuselage 100, and a motor lifting device 600 is fixedly installed below the reamer driving device 500. The motor lifting device 600 is connected to the inside of the fuselage 100 by bolts, and the inside of the fuselage 100 is A control valve assembly 900 is provided below.

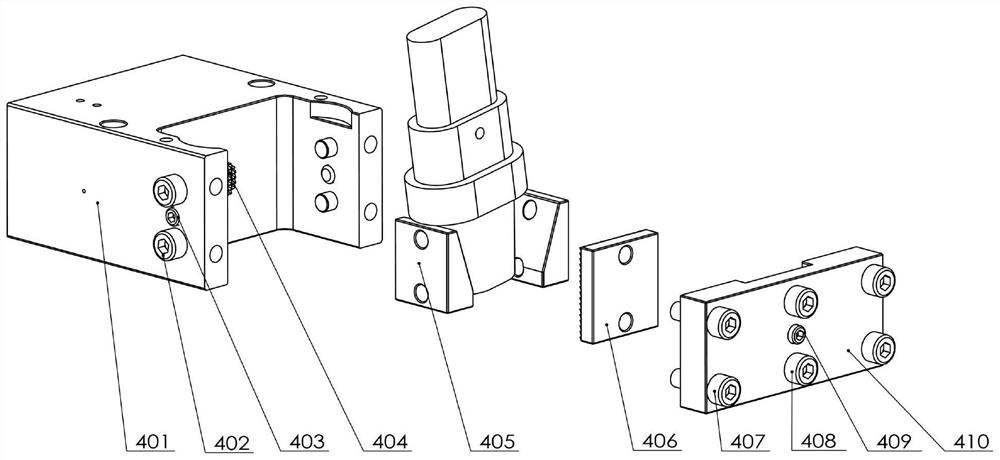

[0023] In this example, a nozzle clamping device 400 is provided on the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com