Liquid feed additive for ruminants and preparation method thereof

A liquid feed, ruminant technology, applied in the direction of animal feed, animal feed, application, etc., to avoid acidosis, improve rumen fermentation capacity, and promote the effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, 60 kg of astragalus extract, 30 kg of epimedium extract, 30 kg of malic acid, 80 kg of calcium citrate, 20 kg of chitosan oligosaccharide, and 2 kg of disodium fumarate were added to each ton of Clostridium butyricum fermentation waste liquid.

[0028] The preparation method of the liquid feed additive for ruminants of the present embodiment is as follows: first add 200kg of purified water into the liquid preparation tank, then add 60kg of astragalus extract, 30kg of malic acid, 80kg of calcium citrate, 20kg of chitosan oligosaccharides, 2kg of rich Disodium maleate, after heating and dissolving at 42°C, dissolve 30kg of Epimedium extract with 160kg of propylene glycol and pour it into the liquid preparation tank, heat to 100°C and boil for 30 minutes, then circulate cold water to cool down to room temperature, then add 1 ton of butyric acid Clostridium fermentation waste liquid, adjust the pH to 5.5-6.5 with sodium hydroxide, stir evenly and fill.

...

Embodiment 2

[0034] In this embodiment, for every ton of Clostridium butyricum fermentation waste liquid, add 80 kg of Astragalus extract, 40 kg of Epimedium extract, 50 kg of malic acid, 90 kg of calcium citrate, 30 kg of chitosan oligosaccharide, and 2 kg of disodium fumarate.

[0035] The preparation method of the liquid feed additive for ruminants of the present embodiment is: first add 200kg purified water in the liquid preparation tank, then add 80kg astragalus extract, 50kg malic acid, 90kg calcium citrate, 30kg chitosan oligosaccharide, 2kg Disodium fumarate, heat and dissolve completely at 42°C, dissolve 40kg of Epimedium extract with 170kg of propylene glycol and pour it into a liquid preparation tank, heat to 100°C and boil for 30 minutes, then circulate cold water to cool down to room temperature, add 1 ton of butyl Clostridium acid fermentation waste liquid, adjust the pH to 5.5-6.5 with sodium hydroxide, stir evenly and fill.

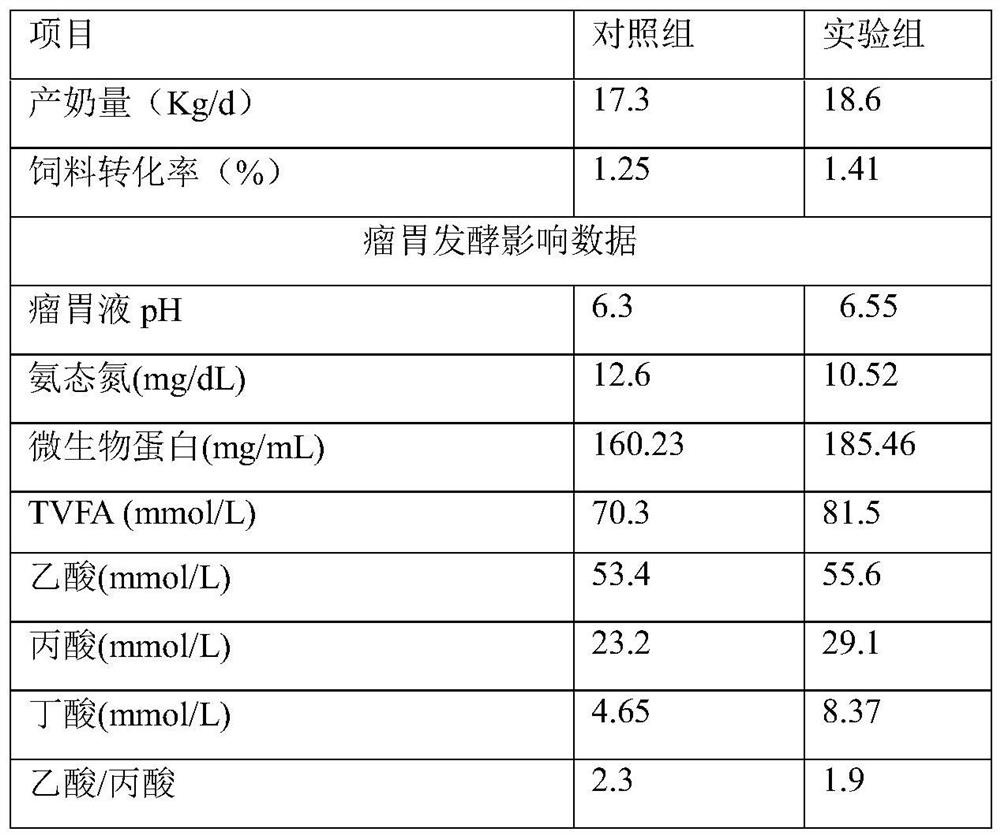

[0036] Effects of use: 40 healthy Holstein cows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com