A method for preparing health-care pre-mixed wine by using brandy distillation raffinate

A technology for brandy and pre-mixed wine, applied in the field of wine products, can solve the problems such as waste of brandy distillation residue, low nutrient content, product instability, etc., and achieve the effects of improving the utilization value, increasing the fragrance, and having a fresh and refreshing taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

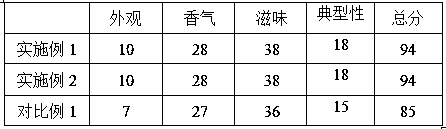

Examples

Embodiment 1

[0027] 1.1 Add 50g of hematoxylin and 20g of sumac charcoal to every 1kg of brandy distillation raffinate, soak at room temperature for 2 days, and filter to obtain the filtrate;

[0028] 1.2 Take 70kg of filtrate, add 30kg of grape wine with an alcohol content of 12%, after mixing evenly, add 7.5kg of white sugar and 0.15kg of ethyl maltol, pour it into stainless steel, mix evenly, and get a mixed liquor;

[0029] 1.3 Storage: add sulfurous acid solution with a concentration of 60 mg / L to the mixed wine liquor, accounting for 3% of its total weight, and store it below 20°C for 3 months to obtain pre-mixed wine;

[0030] 1.4 Stability treatment: at a temperature of 15-16°C, add 0.2g of chitosan and 0.8g of bentonite per liter of pre-mixed wine for the first gelling treatment, filter with diatomaceous earth after 10 days, and then Add 0.5g of PVP and 0.6g of bentonite to the wine to carry out the second glue treatment, and then perform plate and frame filtration to obtain a cla...

Embodiment 2

[0033] 2.1 Add 50g of sumac and 20g of sumac charcoal to every 1kg of brandy distillation raffinate, soak at room temperature for 1d, and filter to obtain the filtrate;

[0034] 2.2 Take 70kg of filtrate, add 30kg of grape wine with an alcohol content of 12%, after mixing evenly, add 7.5kg of white granulated sugar, pour it into stainless steel, mix evenly, and get mixed liquor;

[0035] 2.3 Storage: add 70mg / L sulfurous acid solution with a concentration of 3% of the total weight to the mixed wine, and store it below 20°C for 3 months to obtain pre-mixed wine;

[0036] 2.4 Stability treatment: at a temperature of 15-16°C, add 0.2g of chitosan and 0.8g of bentonite per liter of pre-mixed wine for the first gelling treatment, filter with diatomaceous earth after 15 days, and then Add 0.5g of PVP and 0.6g of bentonite to the wine to carry out the second glue treatment, and then perform plate and frame filtration to obtain a clarified pre-mixed wine;

[0037] 2.5 Sterilization a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com