A super-flexible nickel-titanium alloy intracranial stent with micro-nano structure

A technology of intracranial blood vessels and micro-nano structures, applied in the field of medical devices, can solve problems such as inconsistent diameters of blood vessels, poor adherence, and extension into aneurysms, so as to improve flexibility and adherence, reduce discounts and ovalization, The effect of promoting vascular endothelialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

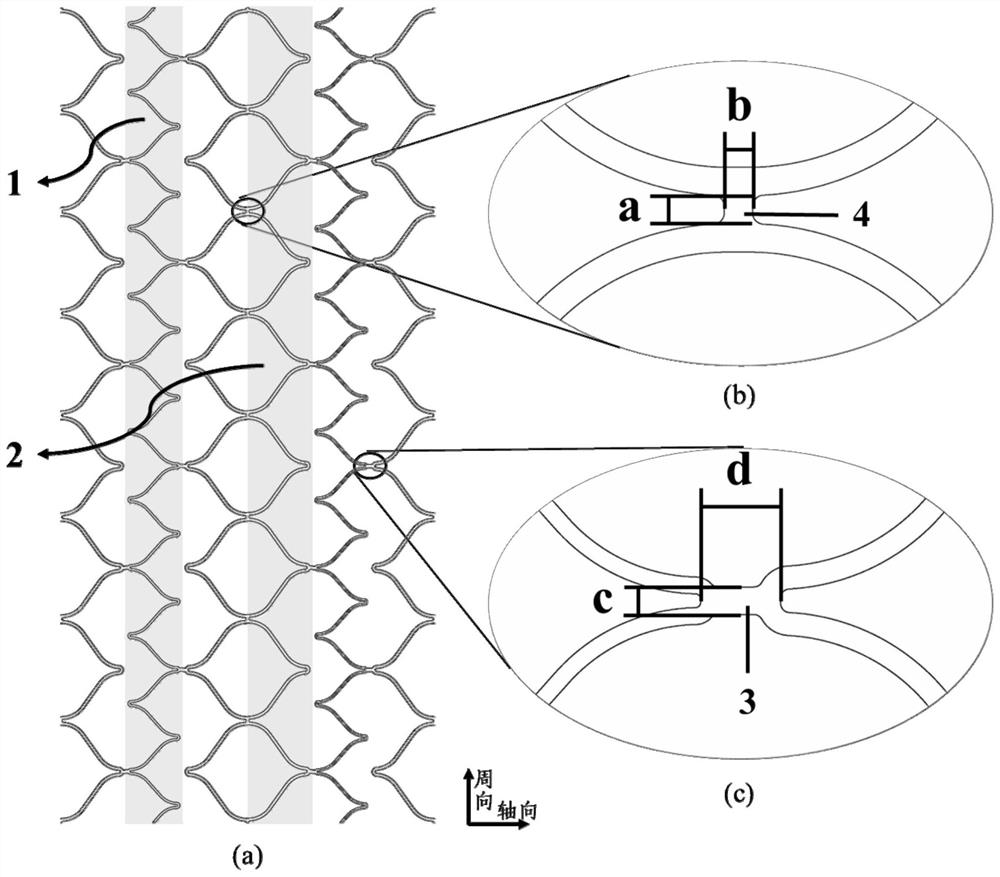

[0044] 本实施例设计了一种具有微纳结构的超柔顺镍钛合金颅内血管支架,设计的中间部位采用闭环结构局部增强,长度为2.25mm;开环结构占整个颅内血管支架表面积的30%;第二V字形单元2丝宽为0.05mm,第一V字形单元1丝宽为0.0367mm,连接杆(b)高度a为0.05mm,宽度b为0.05mm,连接杆(c)高度c为0.06mm,宽度d为0.0857mm。第一V字形单元1长度尺寸与宽度尺寸比为0.84,第二V字形单元2高度尺寸与宽度尺寸比为0.6~0.7。

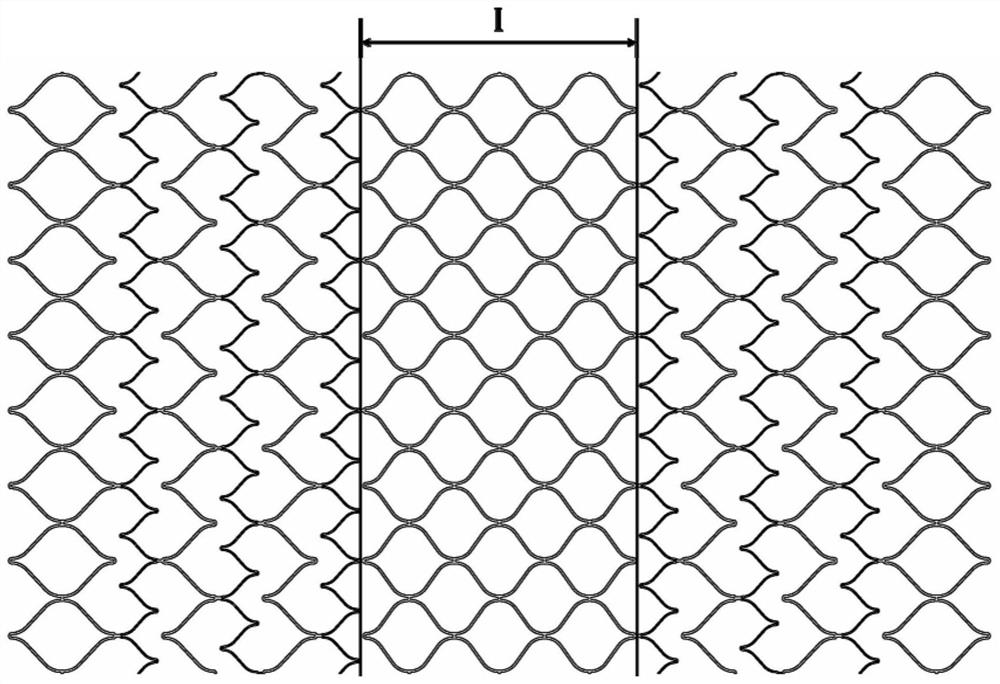

[0045] Such as image 3 所示,颅内血管支架平面展开切割图。 根据设计图纸在外径为2.8mm的镍钛合金管上进行激光切割,清洗,模具扩张,热处理去应力定型,电解抛光,再次清洗等步骤制备可得最终颅内血管支架。 Such as Figure 4 所示,颅内血管支架标称直径为4.5mm,长度为25mm,显影杆长度为0.7mm,显影杆宽度为0.15mm,壁厚为0.05mm。

Embodiment 2

[0047] 本实施例对实施例1中加工的支架进行三点弯曲实验测试,以表征支架的柔顺性。 三点弯曲实验设备由两个下方固定支撑部件(4mm直径平行圆柱)和一个上方加载部件(4mm直径圆柱)组成。 采用固定跨距三点弯曲方法,下方固定支撑部件的跨距设置为20mm。 Proceed as follows:

[0048] a)装配放样:将样品垂直于固定支撑部件放置,加载部件平行于固定支撑部件进行装配,并使其处于两固定支撑部件的正中。

[0049] b)启动测试:以0.05mm / s的恒定速率施加载荷直到预定的最大挠度4.5mm。

[0050] c)记录在整个试验过程中样品是否表现出充分均匀的弯曲,并绘制载荷随挠度变化曲线。

[0051] Such as Figure 5 为三点弯曲实验测试结果。 Such as Figure 5 (a)所示,过程中支架弯曲程度,整个试验过程中支架表现出充分均匀的弯曲,未出现打折、椭圆化的现象。 Such as Figure 5 (b)所示,支架载荷-挠度曲线,计算挠度为2.75mm时实施例1支架的弯矩为0.149N*mm,低于Enterprise(0.772N*mm)闭环支架、Solitaire(0.428N*mm)闭环支架,且优于Neuroform(0.235N*mm)开环支架。

Embodiment 3

[0053] 本实施例在释放和压缩的过程中,测定实施例1中加工的支架径向支撑力与支架直径之间的关系,以表征支架的支撑性能。分别采用径向压握法和平板法:

[0054] 1.径向压握法:

[0055] a)将支架放置到设备当中,设备初始孔径被设置为7mm;

[0056] b)将支架直径以0.0156mm / s的速度减小至0.5mm;

[0057] c)然后孔径以0.0156mm / s的速度增加,并且支架被缓慢卸载至4.5mm;

[0058] d)在支架压握过程中,记录径向力与支架直径之间的关系。

[0059] 2.平板法:

[0060] a)将支架放置于两平板之间,并使其处于部件中心,调节压头刚好贴于支架表面;

[0061] b)以0.05mm / s的恒定速率施加载荷直到位移达到支架直径的50%(即2.25mm),再以相同的速度回位;

[0062] c)记录载荷-位移曲线。

[0063] Such as Image 6 为支架径向支撑性能测试结果。 Such as Image 6 (a)所示,采用径向压握法测试径向支撑力随直径变化曲线,在目标血管直径3.0mm、4.0mm处实施例1支架径向支撑力分别为1.58N、0.929N;如 Image 6 (b)所示,采用平板法测试平板支撑力随变形量变化曲线,在变形量达到支架直径的50%(即2.25mm)时,开环支架力值达到0.01605N / mm,高于Neuroform(0.0065N / mm)开环支架、Enterprise(0.0082N / mm)闭环支架、Solitaire(0.0106N / mm)闭环支架,具有足够的径向支撑力。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com