Plastic hollow polymer microspheres with microchannels on surfaces as well as preparation method and application of microspheres

A technology of polymers and micropores, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulations, etc. Problems such as inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

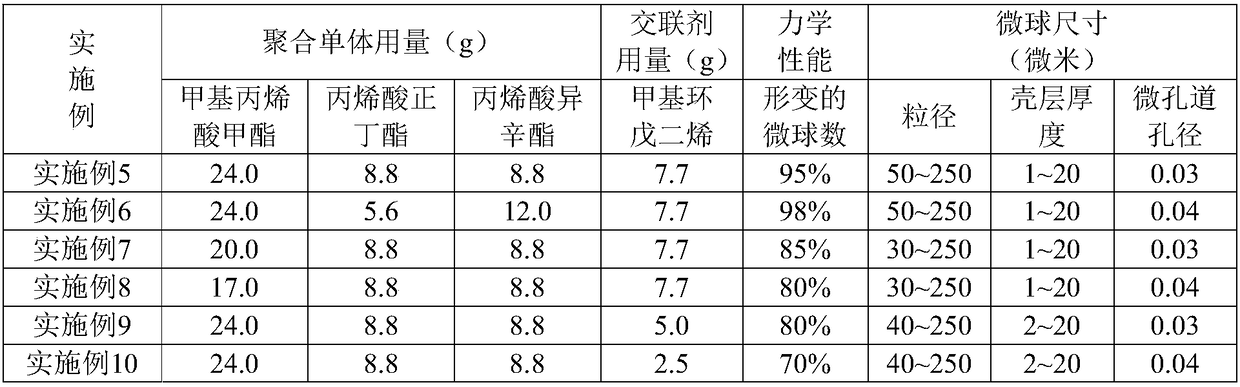

Examples

preparation example Construction

[0059] In a preferred embodiment of the present invention, the preparation method includes the following steps: firstly adding the organic solvent into the aqueous solution in which the colloidal protective agent is dissolved, stirring at room temperature to disperse the organic solvent, and gradually raising the temperature to obtain water an oil-in-type micro-droplet suspension; preparing a mixed solution including a polymerization monomer, an initiator and a cross-linking agent; adding the mixed solution dropwise to the suspension. By controlling the amount of the organic solvent, the polymerization reaction is gradually carried out on the surface of the micro-droplet, thereby forming a cross-linked polymer shell on the surface of the micro-droplet. At the initial stage of polymer shell formation, the organic solvent wrapped in the polymer shell is slowly volatilized by controlling the temperature of the system to form hollow polymer plastic microspheres with micropores on t...

Embodiment 1

[0080] A method for preparing cross-linked polymethyl methacrylate-n-butyl acrylate-isooctyl acrylate hollow polymer plastic microspheres with micropores on the surface, the specific operation steps are as follows:

[0081] (1) The reactor equipped with a stirrer and a reflux condensing device is placed in a water bath, and successively add 5% polyvinyl alcohol 1788 (molecular weight is 1700, alcoholysis degree is 88%) aqueous solution 300.0% to the reactor g and 57.0 g of methylcyclohexane, adjust the stirring speed to 600 rpm / min, stir at room temperature for 10 minutes, start to heat up and stabilize the system temperature at 75 ° C, forming a stable oil-in-water micro-droplet suspension.

[0082] (2) 12.0g n-butyl acrylate, 24.0g methyl methacrylate, 5.6g isooctyl acrylate and 7.7g methylcyclopentadiene were placed in a beaker, and 1.2g azobisisoheptanonitrile was added, Stir until the diisoheptanonitrile is completely dissolved to form a uniform mixed solution.

[0083] ...

Embodiment 2

[0091] A method for preparing cross-linked polymethyl methacrylate-n-butyl acrylate-isooctyl acrylate hollow polymer plastic microspheres with micropores on the surface, the specific operation steps are as follows:

[0092] (1) The reactor equipped with a stirrer and a reflux condensing device is placed in a water bath, and successively add 5% polyvinyl alcohol 1788 (molecular weight is 1700, alcoholysis degree is 88%) aqueous solution 300.0% to the reactor g and 29.4g cyclohexane, adjust the stirring speed to 500rpm / min, stir at room temperature for 10 minutes, start to heat up and stabilize the system temperature at 60°C, forming a stable oil-in-water micro-droplet suspension.

[0093] (2) 8.0g n-butyl acrylate, 24.0g methyl methacrylate, 5.6g isooctyl acrylate and 5.7g methylcyclopentadiene are placed in a beaker, and 0.7g benzoyl peroxide is added, stirred Until the benzoyl oxide is completely dissolved to form a uniform mixed solution.

[0094] (3) Add the mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com