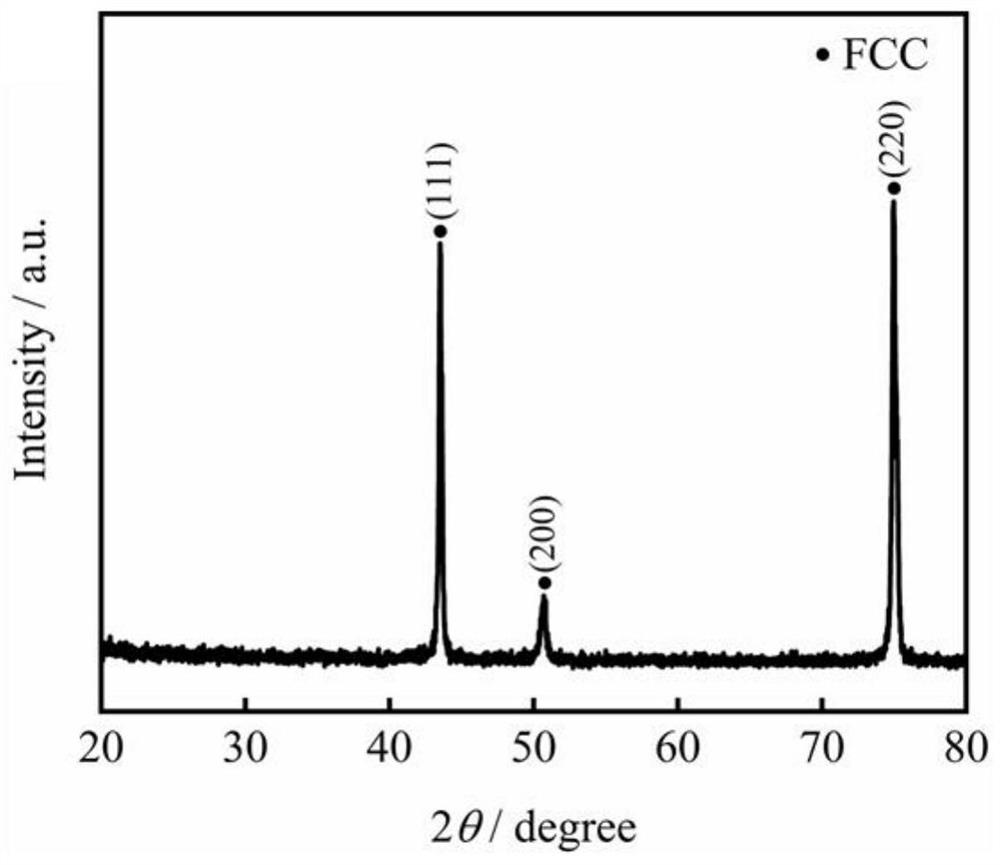

Preparation method of high-strength and high-toughness CrCoNi medium-entropy alloy homogeneous fine-grain thin plate

A high-strength, high-toughness, entropy alloy technology, applied in the field of preparation of high-strength, high-toughness CrCoNi medium-entropy alloy homogeneous fine-grained thin plate, can solve the influence of unpredictable uniformity and directionality of alloy material structure performance, uniformity and High strength, low anisotropy, and reduced anisotropy problems due to problems such as large influence of directionality and undisclosed free forging method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

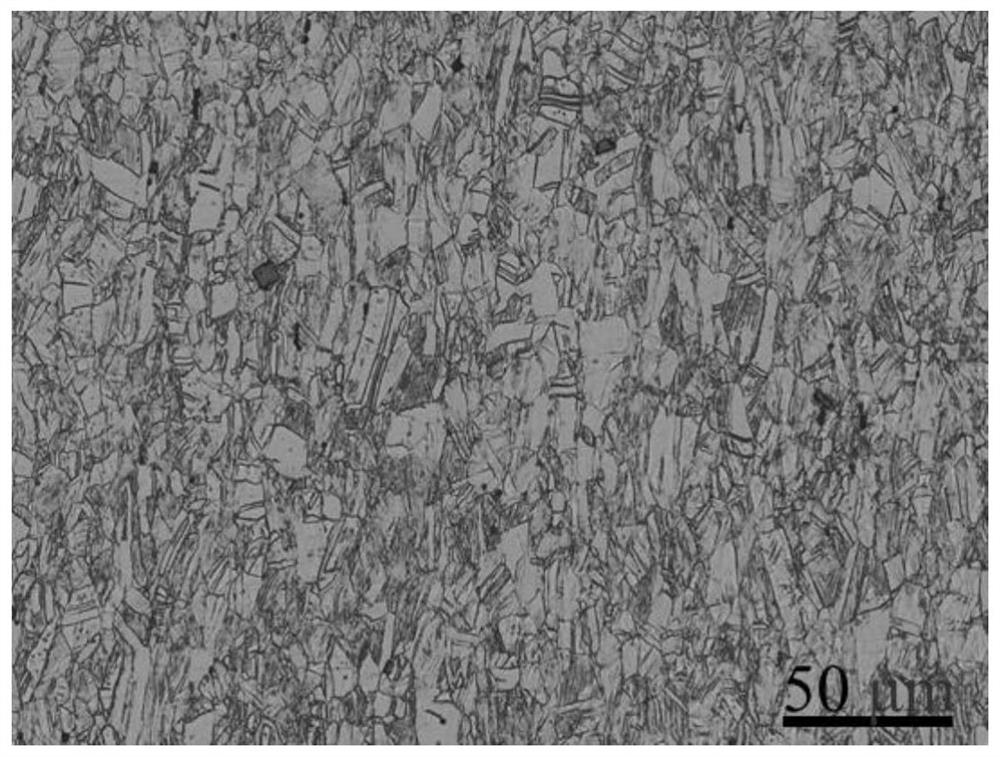

Embodiment 1

[0027] A method for preparing a high-strength and high-toughness CrCoNi medium-entropy alloy homogeneous fine-grained thin plate, the specific steps are as follows:

[0028] (1) Vacuum smelting treatment: take Cr, Co, and Ni raw materials according to the atomic percentage of 25% Cr, 30% Co, and 45% Ni, and put them into vacuum smelting for smelting, the vacuum degree is 0.01-1Pa, and the smelting temperature is 1500-1700°C; Pouring the smelted molten metal into a mold at 300-600°C, cooling and molding to make an ingot;

[0029] (2) Annealing of alloy ingots: Heating the ingots at a controlled rate of 5°C / min to 1000°C, holding the heat for 1-5 hours, cooling with the furnace to below 180°C, and then air-cooling;

[0030] (3) Forging billet drawing length: the annealed ingot is subjected to upsetting and elongation forging to obtain a slab (size: 600mm×120mm×120mm); the initial forging temperature is 1150°C, and the final forging temperature is 1100°C , the thickening speed o...

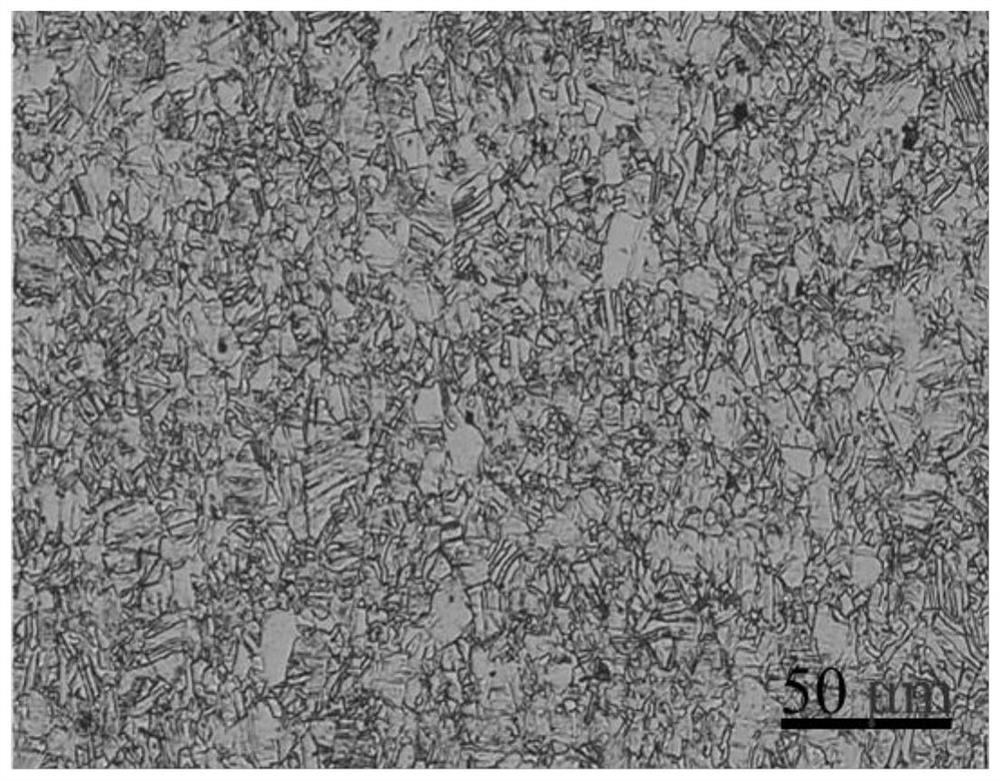

Embodiment 2

[0033] A method for preparing a high-strength and high-toughness CrCoNi medium-entropy alloy homogeneous fine-grained thin plate, the specific steps are as follows:

[0034](1) Vacuum smelting treatment: take Cr, Co, and Ni raw materials according to the atomic percentage of 30% Cr, 35% Co, and 35% Ni, and put them into vacuum smelting for smelting, the vacuum degree is 0.01-1Pa, and the melting temperature is 1500-1700°C; Pouring the smelted molten metal into a mold at 300-600°C, cooling and molding to make an ingot;

[0035] (2) Annealing of alloy ingots: Heating the ingots at a controlled rate of 5°C / min to 1000°C, holding the heat for 1-5 hours, cooling with the furnace to below 180°C, and then air-cooling;

[0036] (3) Forging billet drawing length: the annealed ingot is subjected to upsetting and elongation forging to obtain a slab (size: 600mm×120mm×120mm); the initial forging temperature is 1150°C, and the final forging temperature is 1100°C , the roughing speed of bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com