Laminate, and method for producing laminate

A manufacturing method and laminated body technology, applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problems of more damage, difficult peeling, easy cracking of polymer films, etc., and achieve sufficient heat resistance and adhesion good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

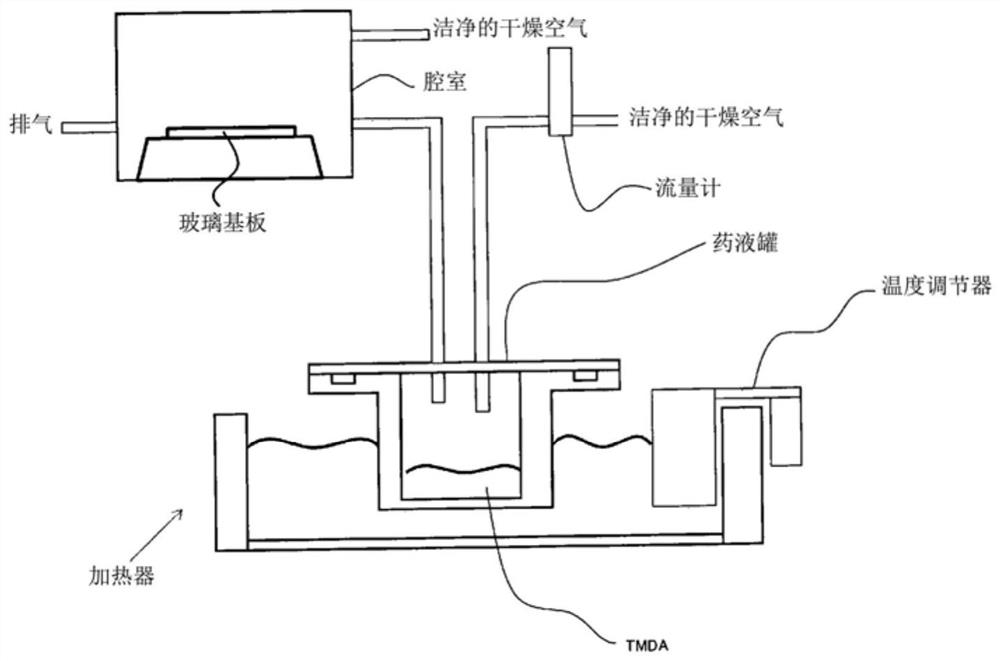

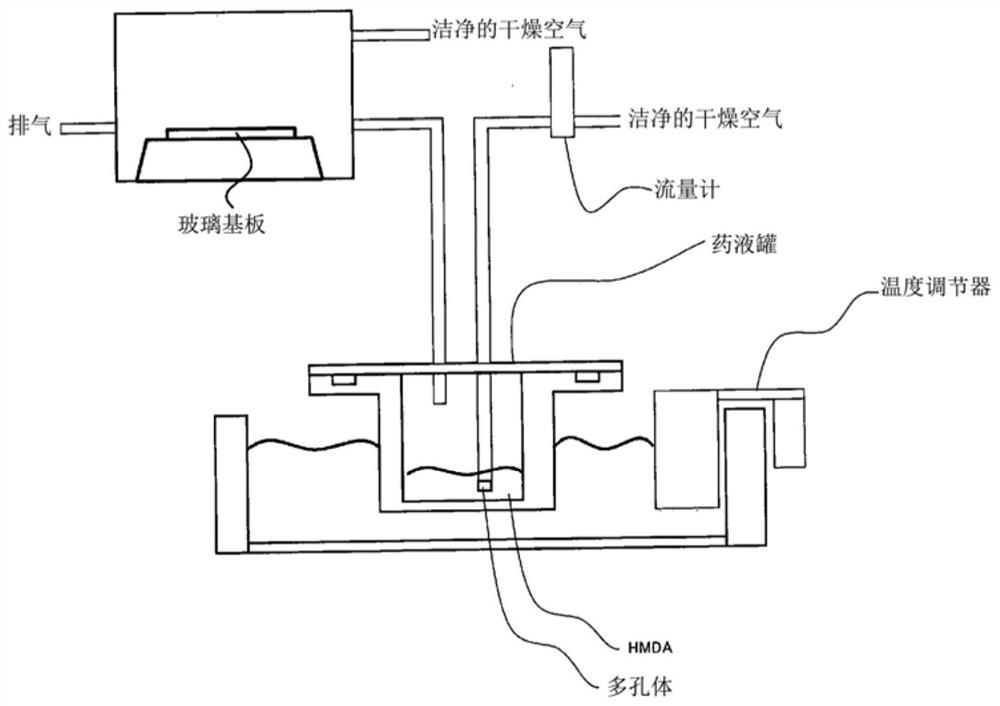

Method used

Image

Examples

manufacture example 1

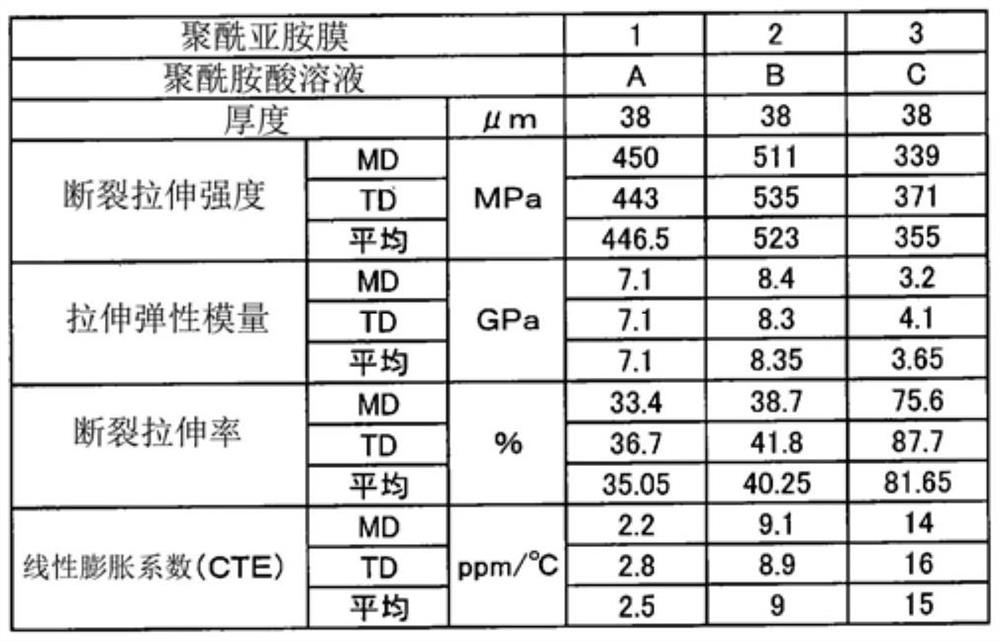

[0136] [Manufacturing Example 1 (Manufacture of Polyamic Acid Solution A)]

[0137] After carrying out nitrogen replacement in the reaction vessel equipped with nitrogen inlet pipe, thermometer and stirring rod, add 223 parts by mass of 5-amino-2-(p-aminophenyl) benzoxazole (DAMBO), N in the above-mentioned reaction vessel, 4416 parts by mass of N-dimethylacetamide, and completely dissolved. Next, together with 217 parts by mass of pyromellitic dianhydride (PMDA), SNOWTEX (DMAC-ST30, Nissan Chemical Co. Industrial production), and make colloidal silicon dioxide relative to the total amount of the polymer solid content in the polyamic acid solution A 0.7% by mass, carry out heating and stirring for 24 hours at a reaction temperature of 25° C., to obtain a brown viscous poly Amic acid solution A.

manufacture example 2

[0138] [Manufacturing Example 2 (Manufacture of Polyamic Acid Solution B)]

[0139] After carrying out nitrogen replacement in the reaction vessel equipped with nitrogen introduction pipe, thermometer and stirring rod, add 398 parts by mass of 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) in the above reaction vessel, 4600 parts by mass of N,N-dimethylacetamide were fully stirred to make them uniform. Next, 147 parts by mass of p-phenylenediamine (PDA) was added to BPDA, and SNOWTEX (DMAC-ST30, Nissan Chemical Industrial production), and make colloidal silicon dioxide relative to the total amount of polymer solid content in polyamic acid solution B be 0.7 mass %, stir at 25 ℃ of reaction temperature for 24 hours, obtain brown viscous polyamic acid Solution B.

manufacture example 3

[0140] [Manufacturing Example 3 (Manufacture of Polyamic Acid Solution C)]

[0141] After nitrogen replacement is carried out in the reaction vessel equipped with nitrogen inlet pipe, thermometer and stirring rod, pyromellitic anhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) are added in the above reaction vessel in an equivalent amount, and dissolved in N,N-dimethylacetamide, added SNOWTEX (DMAC-ST30, manufactured by Nissan Chemical Industries) formed by dispersing colloidal silica (average particle size: 0.08 μm) in dimethylacetamide, And make the colloidal silica relative to the total amount of the polymer solid content in the polyamic acid solution C be 0.7 mass, and stir at a reaction temperature of 25° C. for 24 hours to obtain a brown viscous polyamic acid solution C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com