Photosensitive resin composition and cured product thereof

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition and its cured product, can solve the problems of insufficient developing property, heat resistance and adhesiveness, etc., and achieve the effect of excellent sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

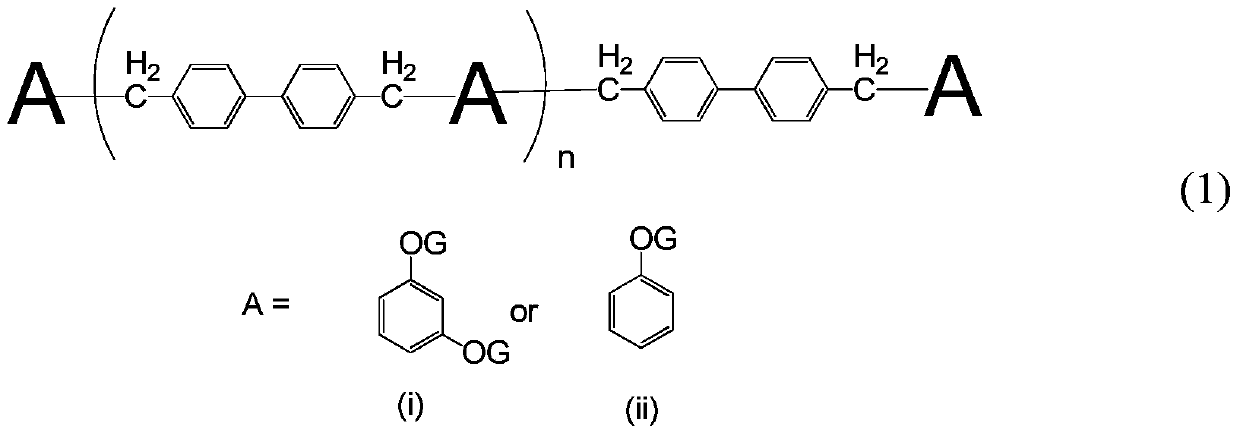

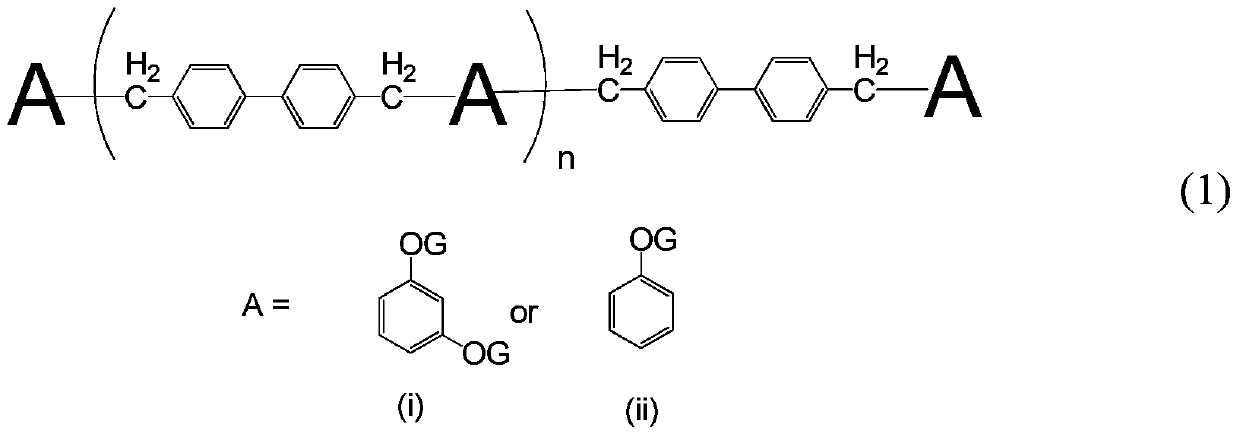

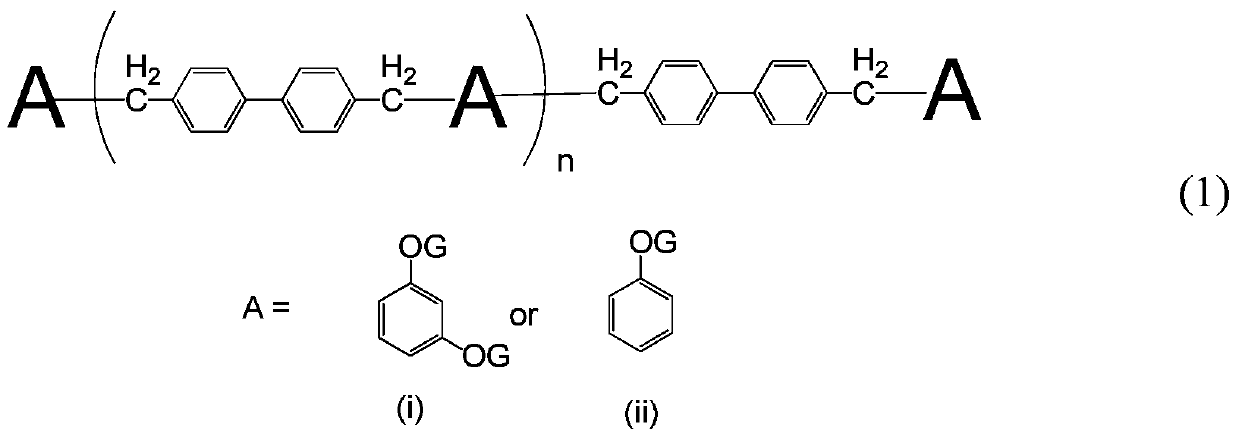

Method used

Image

Examples

Synthetic example 1

[0089] In a 3L flask equipped with a stirring device and a reflux tube, add Nippon Kayaku (Stock) EOCN-103S (multifunctional cresol novolak type epoxy resin, epoxy equivalent: 215.0g / equivalent) 860.0g as in the molecule Epoxy compound (a) having two or more epoxy groups, 288.3 g of acrylic acid (molecular weight: 72.06) as monocarboxylic acid (b) having an ethylenically unsaturated group in the molecule, 492.1 g of carbitol acetate As a reaction solvent, 4.921 g of 2,6-di-tert-butyl-p-cresol as a polymerization inhibitor, and 4.921 g of triphenylphosphine as a reaction catalyst, react at 98°C until the acid value of the reaction liquid becomes 0.5 mg·KOH / g or less, the epoxy carboxylate compound can be obtained. Then, 169.8 g of carbitol acetate as a reaction solvent and 201.6 g of tetrahydrophthalic anhydride as a polybasic acid anhydride (c) were added to the reaction liquid, and reacted at 95° C. for 4 hours to obtain a soluble resin containing an aqueous alkali solution (...

Synthetic example 2

[0091] In a 1L flask equipped with a stirring device and a reflux tube, add 209.0 g of NC-3500 (biphenol type epoxy resin, epoxy equivalent: 209.0 g / equivalent) manufactured by Nippon Kayaku Co., Ltd. The above epoxy compound (a), acrylic acid (molecular weight: 72.06) 72.06g as a monocarboxylic acid (b) having an ethylenically unsaturated group in the molecule, and 121.39g of carbitol acetate for the reaction Solvent, 0.850g of 2,6-di-tert-butyl-p-cresol as a polymerization inhibitor, and 0.850g of triphenylphosphine as a reaction catalyst, react at 98°C until the acid value of the reaction solution becomes 0.5mg·KOH / g or less, an epoxy carboxylate compound is produced. Then, 86.32 g of carbitol acetate as a reaction solvent and 102.51 g of tetrahydrophthalic anhydride as a polybasic acid anhydride (c) were added to the reaction liquid, and reacted at 95° C. for 4 hours to obtain a soluble resin containing an aqueous alkali solution ( A1') 65% by mass resin solution (let th...

Synthetic example 3

[0093] In a 3L flask equipped with a stirring device and a reflux tube, add 368.0 g of RE-310S (2-functional bisphenol-A epoxy resin, epoxy equivalent: 184.0 g / equivalent) manufactured by Nippon Kayaku (Co., Ltd.) as the molecule Epoxy compound (d) having two or more epoxy groups, 141.2 g of acrylic acid (molecular weight: 72.06) as monocarboxylic acid (b) having an ethylenically unsaturated group in the molecule, hydroquinone monomethyl ether 1.02 g as a polymerization inhibitor, and 1.53 g of triphenylphosphine as a reaction catalyst, react at 98°C until the acid value of the reaction solution becomes below 0.5 mg·KOH / g to obtain an epoxy carboxylate compound (molecular weight: 509.2) . Then, 755.5 g of carbitol acetate and 268.3 g of 2,2-bis(dimethylol)-propionic acid (molecular weight: 134.16) were added as a solvent for the reaction to this reaction liquid as a solvent having two The carboxylic acid (f) of the hydroxyl group, 1.08 g of 2-methylhydroquinone as a thermal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com