Inner electrode copper paste for low-temperature co-fired ceramic, and preparation method and application thereof

A technology of low-temperature co-fired ceramics and internal electrodes, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., which can solve the problems of poor combination of conductivity and achieve good co-firing Matching, reduced warping, and excellent printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

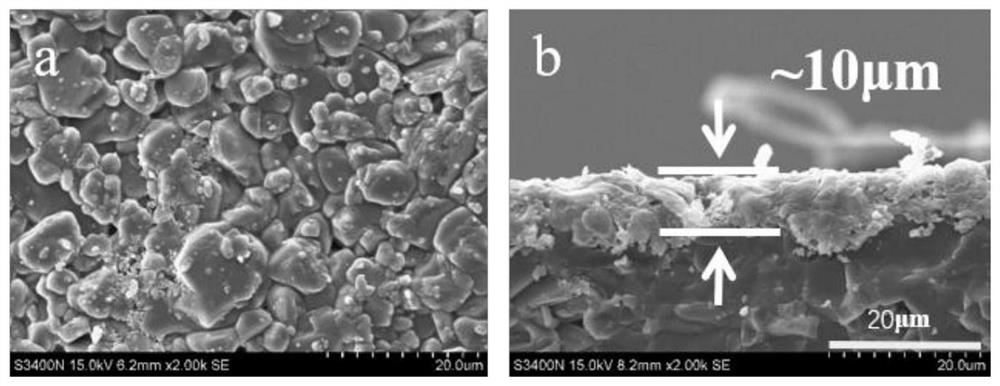

Embodiment 1

[0033] 1. Prepare a mixed solution of deionized water: ethanol with a mass ratio of 10:3, mix copper powder, citric acid, ascorbic acid, and polyvinylpyrrolidone at a mass ratio of 4:2:2:1, and mix the above mixed solution with the powder (copper powder, citric acid, ascorbic acid, polyvinylpyrrolidone) mixed in a volume ratio of 3:1, placed on a magnetic stirrer and stirred in a water bath at 50-80°C for 10 hours, and then placed in a cell pulverizer for 6 hours to obtain pretreated copper powder.

[0034] 2. Add 38wt% SiO 2 , 16 wt% HfO 2 , 8 wt% Al 2 o 3 , 38wt% CuO into a corundum crucible, stir it well with a glass rod, put it into a high-temperature sintering furnace, and preheat it at 400°C for 10 minutes; after the heat preservation, raise the temperature to 1400°C at 10°C / min 30 minutes; fill a 1.4L stainless steel container with deionized water and place it near the high-temperature sintering furnace; take out the molten glass powder with a sampling clamp, and th...

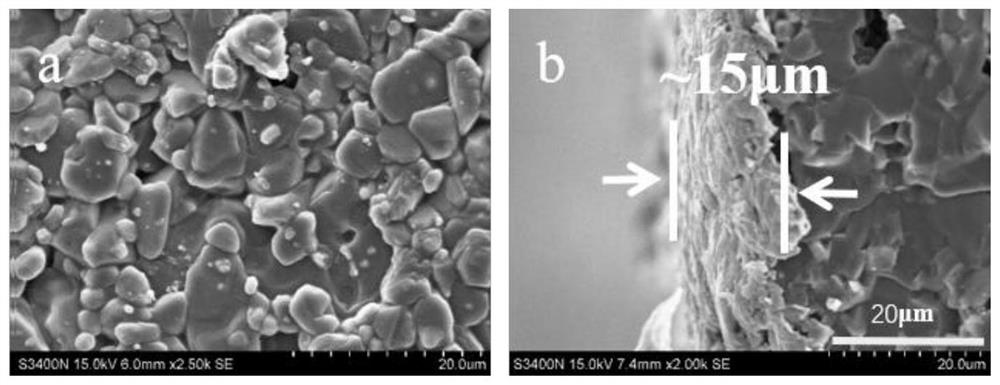

Embodiment 2

[0038] 1. Configure a mixed solution with a mass ratio of deionized water: ethanol = 5-10:1-4, mix copper powder with citric acid, ascorbic acid, and polyvinylpyrrolidone at a mass ratio of 4:2:2:1, and mix the solution with The powder is mixed according to the volume ratio of 3:1, placed on a magnetic stirrer and stirred in a water bath at 50-80°C for 5-10 hours, and then placed in an ultrasonic pulverizer for 3-10 hours to obtain pretreated copper powder.

[0039] 2. Add 38wt% SiO 2 , 16 wt% HfO 2 , 8 wt% Al 2 o 3, 38wt% CuO into a corundum crucible, and fully stir it with a glass rod; put the prepared glass oxide into a high-temperature sintering furnace, and preheat it at 400°C for 10 minutes; Raise the temperature to 1400°C and keep it warm for 30 minutes; fill a 1.4L stainless steel container with deionized water and place it near the high-temperature sintering furnace; take out the molten glass powder with a sampling clamp, and then quickly pour it into a Carry out ...

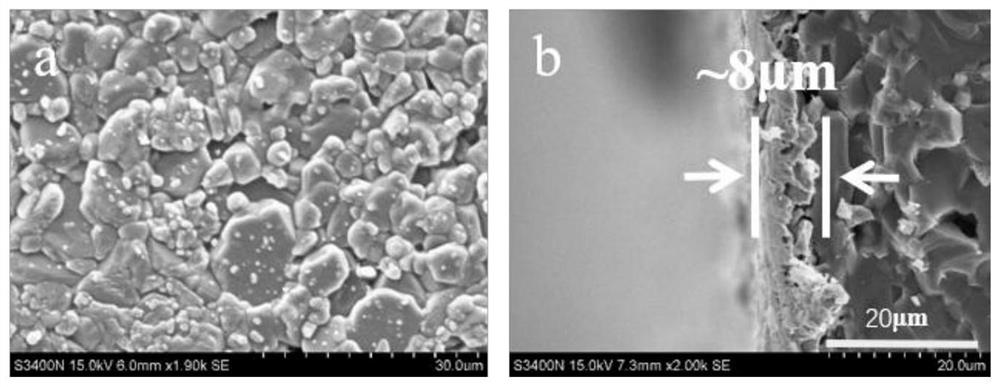

Embodiment 3

[0043] 1. Pretreatment of copper powder: configure a mixed solution with a mass ratio of deionized water: ethanol = 10:3, mix copper powder with citric acid, ascorbic acid, and polyvinylpyrrolidone in a mass ratio of 4:2:2:1, and The solution and the powder are mixed at a volume ratio of 3:1, placed on a magnetic stirrer and stirred in a water bath at 50-80°C for 3-10 hours, and then pulverized in an ultrasonic pulverizer for 3-10 hours to obtain pretreated copper powder.

[0044] 2. Add 38wt% SiO 2 , 16 wt% HfO 2 , 8 wt% Al 2 o 3 Put 38wt% CuO into a corundum crucible, stir it evenly with a glass rod, put it into a high-temperature sintering furnace, heat it at 400°C for 10 minutes to preheat; after heat preservation, raise the temperature to 1400°C at 10°C / min, and hold it for 30 minutes; Fill a 1.4L stainless steel container with deionized water and place it near the high-temperature sintering furnace; take out the molten glass powder with a sampling clip, then quickly p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com