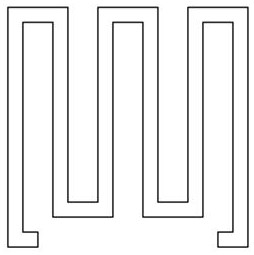

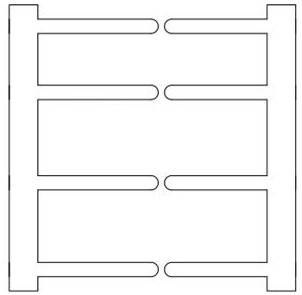

A transitional hole filling paste used for connecting the upper and lower gold and silver layers of the film in the LTCC substrate

A technology for connecting films and substrates, which is applied in the field of transitional hole-filling pastes, can solve problems such as migration, achieve good electrical conductivity, improve sintering density, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

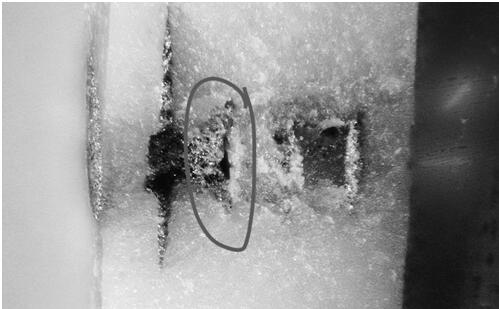

Image

Examples

Embodiment 1

[0024] Weigh 8g of gold powder, 70g of silver powder, 2g of platinum powder, 5g of Ca-B-Si glass powder, 10g of TiN powder, and 5g of organic carrier, stir evenly with a glass rod, and place it for more than 1 hour to complete infiltration, and then roll on a three-roller machine , so that the fineness ≦ 15μm, to obtain transitional hole filling slurry.

Embodiment 2

[0026] Weigh 12.5g of gold powder, 63.5g of silver powder, 7g of platinum powder, 3g of Ca-B-Si glass powder, 9g of TiN powder, and 5g of organic carrier, stir evenly with a glass rod, and place it for more than 1 hour to complete infiltration, and then put it on a three-roll machine Rolling to make the fineness≦15μm, to obtain transitional hole filling slurry.

Embodiment 3

[0028] Weigh 12.5g of gold powder, 63.5g of silver powder, 7g of platinum powder, 3g of Ca-B-Si glass powder, 4g of TiN powder, and 10g of organic carrier, stir evenly with a glass rod, and place it for more than 1 hour to complete infiltration, and then put it on a three-roller machine Rolling to make the fineness≦15μm, to obtain transitional hole filling slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com