Foaming sealant, preparation method thereof and sealing system

A technology of foam sealing and catalyst, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of high construction cost, difficult drying of foam adhesives, poor performance of plugging blocks, etc., and accelerate the curing speed , solve the high environmental humidity dependence, improve the effect of bearing capacity and resilience performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

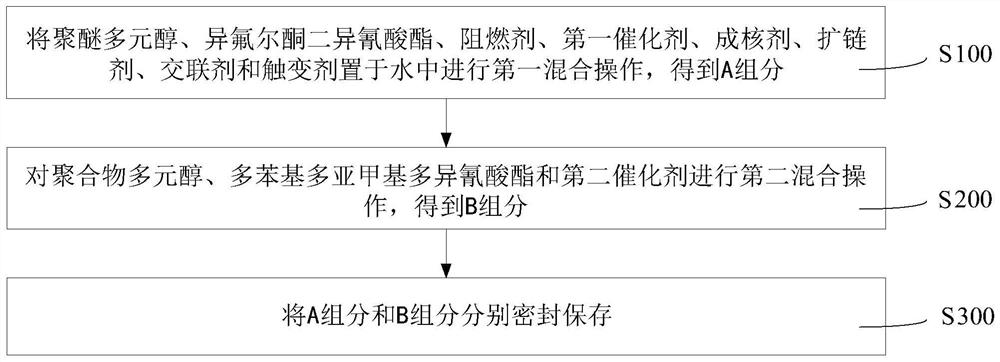

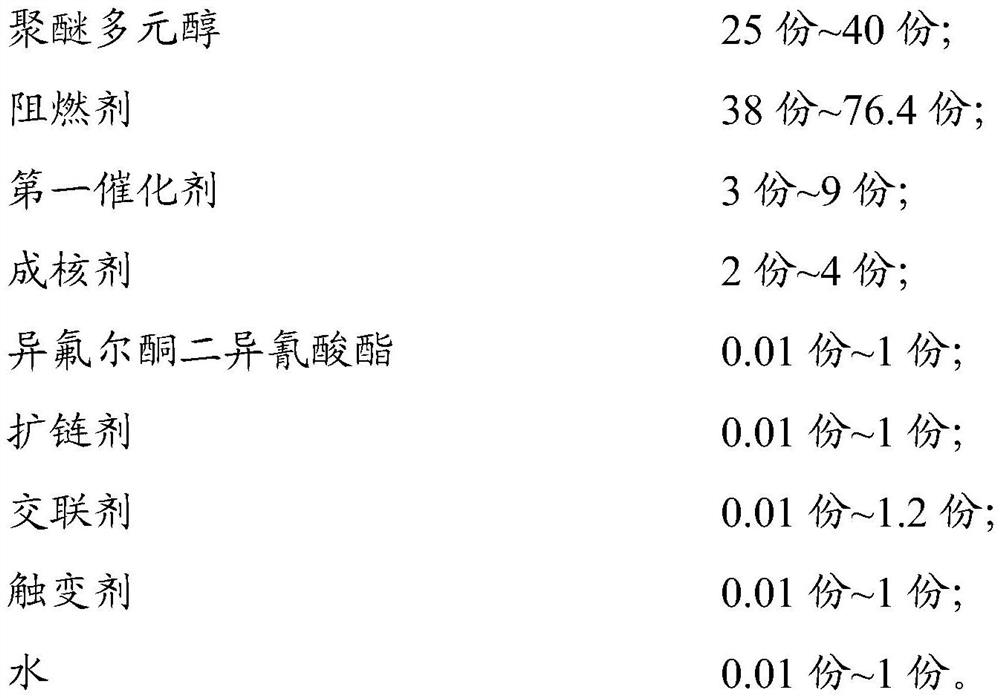

[0048] The present invention also provides a method for preparing a foam sealant, comprising the steps of: mixing polyether polyol, isophorone diisocyanate, a flame retardant, a first catalyst, a nucleating agent, a chain extender, a crosslinking agent and The thixotropic agent is placed in water for the first mixing operation to obtain the A component; the second mixing operation is performed on the polymer polyol, polyphenyl polymethylene polyisocyanate and the second catalyst to obtain the B component; the A group Part and B component are sealed and stored separately.

[0049] In the preparation method of the above-mentioned foaming sealant, polyether polyol, isophorone diisocyanate, flame retardant, first catalyst, nucleating agent, chain extender, crosslinking agent and thixotropic agent are placed in water for The first mixing operation is to obtain the A component containing hydroxyl groups, and then the second mixing operation is performed on the polymer polyol, polyph...

Embodiment 1

[0061]Place polyether polyol 25kg, isophorone diisocyanate 0.01kg, flame retardant 38kg, first catalyst 3kg, nucleating agent 2kg, chain extender 0.01kg, crosslinking agent 0.01kg and thixotropic agent 0.01kg in Carry out the first mixing operation in 1kg of water to obtain A component; carry out the second mixing operation to polymer polyol 50kg, polyphenyl polymethylene polyisocyanate 40kg and the second catalyst 0.01kg to obtain B component; Part and B component are sealed and stored separately.

Embodiment 2

[0063] Put 25kg of polyether polyol, 0.5kg of isophorone diisocyanate, 50kg of flame retardant, 6kg of first catalyst, 3kg of nucleating agent, 0.5kg of chain extender, 0.5kg of crosslinking agent and 0.5kg of thixotropic agent in Carry out the first mixing operation in 0.01kg water to obtain A component;

[0064] 50kg of polymer polyol, 50kg of polyphenyl polymethylene polyisocyanate and 0.5kg of the second catalyst are carried out for the second mixing operation to obtain the B component;

[0065] Keep components A and B separately sealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com