A kind of bismuth telluride thermoelectric material and preparation method thereof

A thermoelectric material, bismuth telluride technology, applied in the field of thermoelectric materials, can solve the problems of difficulty in optimizing the thermoelectric figure of merit of electrical properties, difficult mass production, expensive equipment, etc., to achieve thermoelectric properties and mechanical properties, high textured degree. , the effect of promoting the improvement of the degree of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

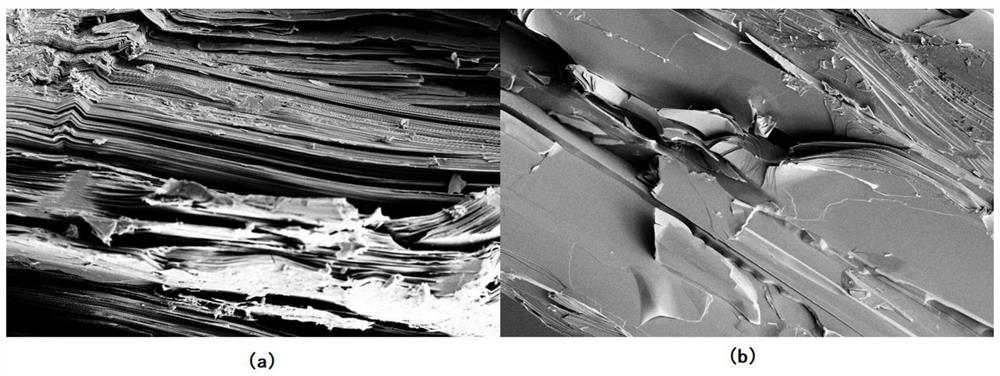

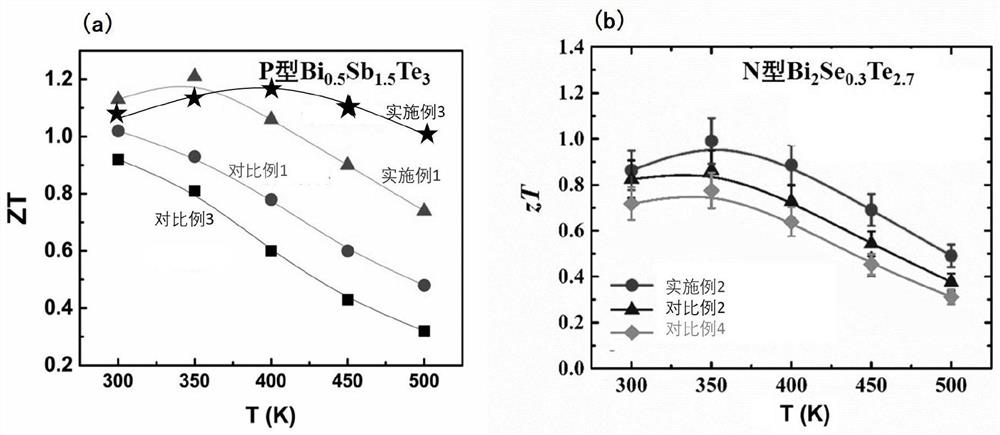

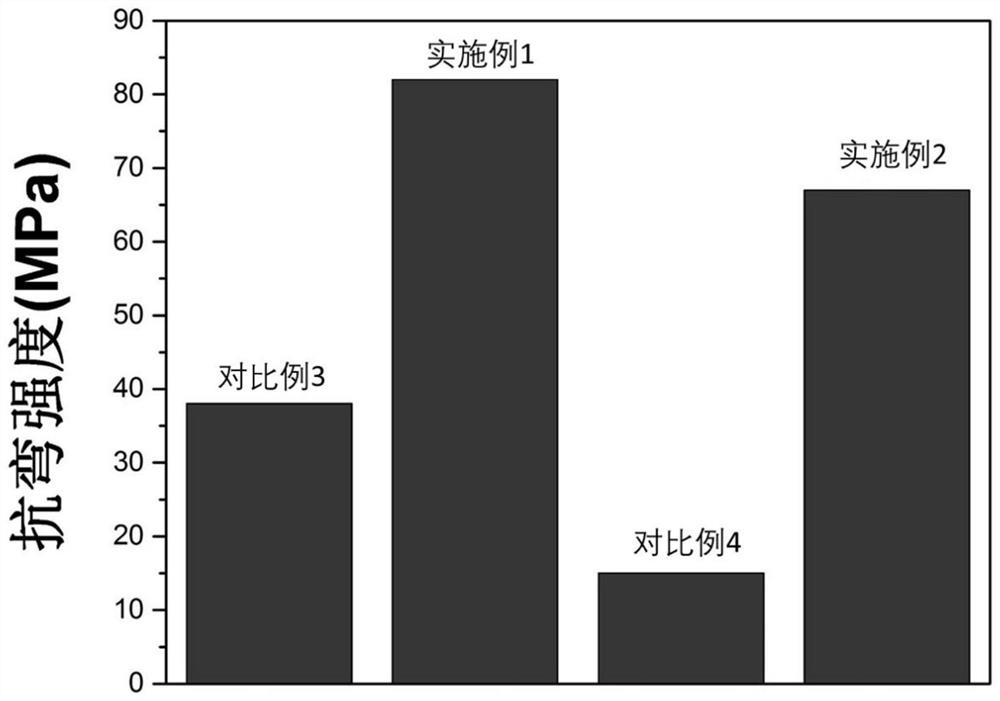

[0028] According to the chemical formula Bi 0.5 Sb 1.5 Te 3 , Weigh the elemental raw materials Bi, Sb and Te (the purity of each element is ≥99.99%) according to the stoichiometric ratio, put the prepared raw materials into a stainless steel ball mill in a glove box filled with high-purity argon, and then carry out a plasma ball mill. High-speed ball milling, the speed of the ball mill is 500 rpm, the power of the plasma generator is set to 2kW, and the ball milling time is 60 minutes. After the powder is fully ground, a sintering mold with a diameter of 15mm is placed in the glove box, and then passed through the sealing device. It was transferred into a vacuum discharge plasma sintering furnace for sintering. The process conditions were that the temperature was raised to a sintering temperature of 400 ℃ at a rate of 100 ℃ per minute, the sintering pressure was kept at 50 MPa, and the sintering time was 15 min to obtain a columnar block material; The body was put into a mo...

Embodiment 2

[0030] According to the chemical formula Bi 2 Te 2.7 Se 0.3, Weigh the elemental raw materials Bi, Sb and Te (the purity of each element is ≥99.99%) according to the stoichiometric ratio, and put the prepared raw materials into the glove box filled with high-purity argon gas. A plasma ball mill is used for high-speed ball milling. The speed of the ball mill is 600 rpm, the power of the plasma generator is set to 1.5kW, and the ball milling time is 60 minutes. After fully grinding the powder, a sintering mold with a diameter of 15mm is placed in the glove box. Then, it is transferred into a vacuum discharge plasma sintering furnace through a sealing device for sintering. The process conditions are that the temperature is raised to a sintering temperature of 400 ℃ at a rate of 100 ℃ per minute, the sintering pressure is kept at 60 MPa, and the sintering time is 10 min to obtain a columnar block material; Afterwards, the columnar block was put into a mold with a diameter of 25 ...

Embodiment 3

[0032] According to the chemical formula Cu 0.002 Bi 0.498 Sb 1.5 Te 3 , Weigh the elemental raw materials Cu, Bi, Sb and Te (the purity of each element is ≥99.99%) according to the stoichiometric ratio, and put the prepared raw materials in a glove box filled with high-purity argon into a zirconia-lined ball mill jar, Then perform high-speed ball milling with a plasma ball mill. The speed of the ball mill is 800 rpm, the power of the plasma generator is set to 0.5 kW, and the ball milling time is 90 minutes. After fully grinding the powder, the glove box is filled with a sintered sinter with a diameter of 10 mm. The mold is then transferred into a vacuum discharge plasma sintering furnace through a sealing device for sintering. The process conditions are that the temperature is raised to a sintering temperature of 450°C at a rate of 100°C per minute, the sintering pressure is maintained at 50MPa, and the sintering time is 10min. After that, the columnar block was put into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com