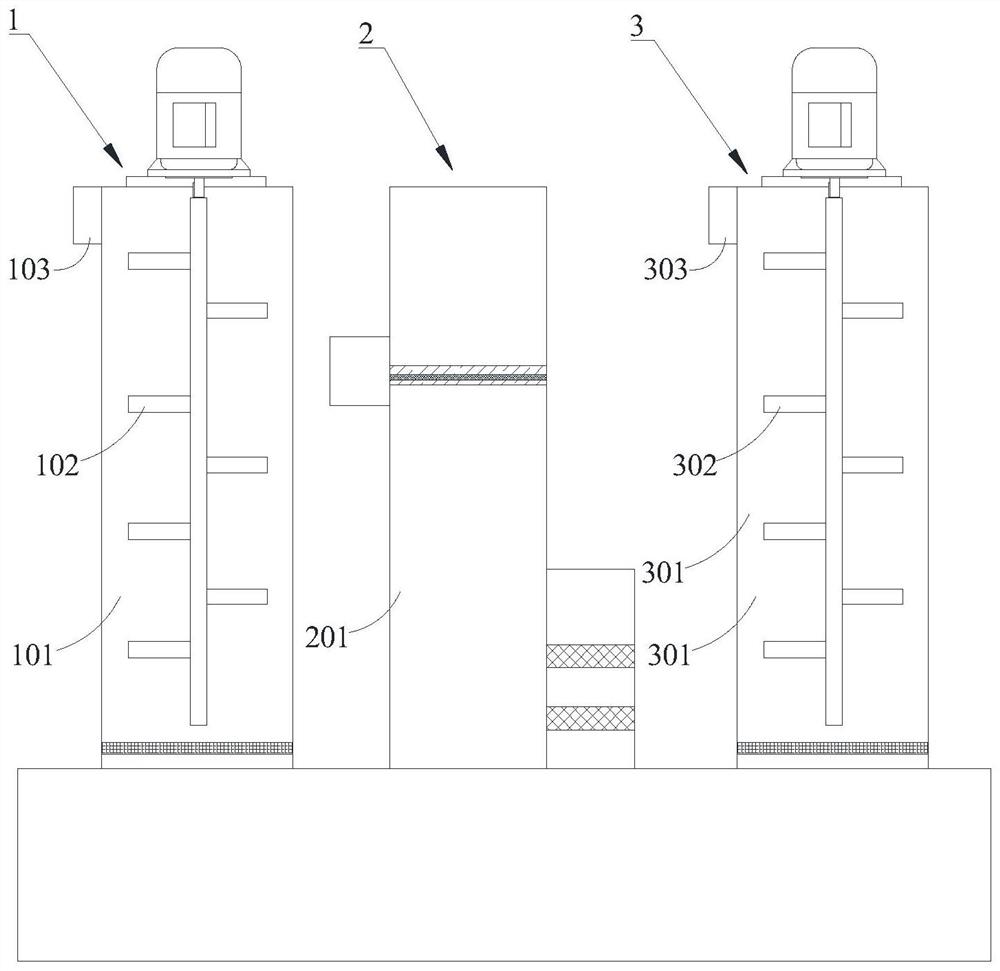

Alumina powder and boehmite mixed amphiphilic agent and mixing equipment

A technology of alumina powder and mixing equipment, applied in the field of alumina, can solve the problems of single characteristic, single composition, inapplicability, etc., and achieve the effect of increasing isolation performance, reducing pore size, and improving isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

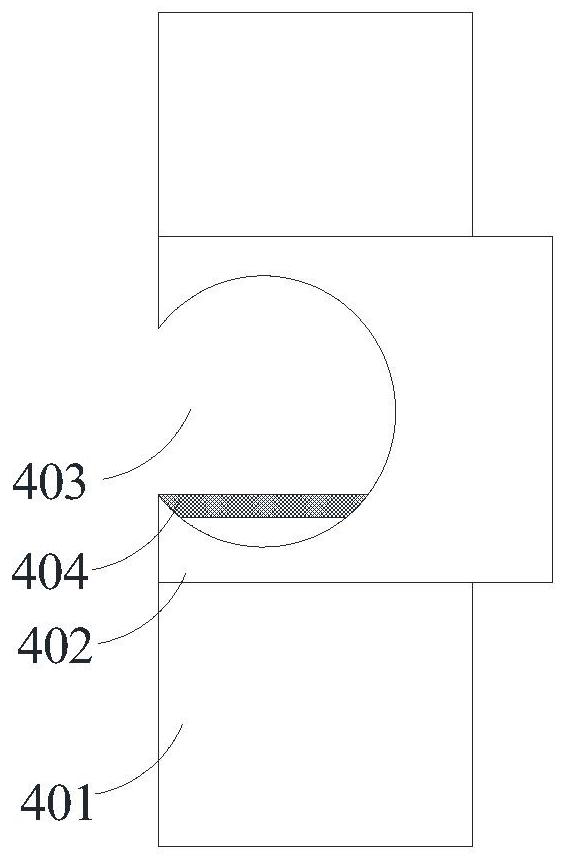

Method used

Image

Examples

Embodiment 1

[0036] A mixed amphoteric agent of alumina powder and boehmite, comprising: a mixed powder of alumina powder and boehmite powder; the particle size of the alumina powder is 80-90 nanometers; the particle size of the boehmite powder is 50- 60 nanometers; alumina powder 70-82wt%; boehmite powder 8-20wt%. It also includes: nicotinamide adenine dinucleotide phosphate; the weight ratio of nicotinamide adenine dinucleotide phosphate to the mixed powder is 1:9 to 1:10. The mixed powder also includes polyphenylene ether sulfone; the content of polyphenylene ether sulfone is 2-4wt%. The mixed powder also includes sodium metaaluminate and urea; the content of sodium metaaluminate is 3-7wt%; the content of urea is 3-7wt%.

[0037]The beneficial effect of the present invention is that the boehmite of the present invention is mixed into the alumina powder, so that when the alumina powder is made into an alumina film, the water content is reduced, thereby increasing the isolation performan...

Embodiment approach

[0039] Another optional embodiment of the present invention: a mixed amphoteric agent of alumina powder and boehmite, including 70wt% alumina powder, 10wt% boehmite powder, and 10wt% nicotinamide adenine Dinucleotide phosphate, 2wt% polyphenylene ether sulfone, 5wt% sodium metaaluminate and 3wt% urea.

[0040] Put 10wt% nicotinamide adenine dinucleotide phosphate and 2wt% polyphenylene ether sulfone into a hydrothermal reaction kettle, carry out a hydrothermal reaction for 30 minutes, and carry out low-temperature cooling at 0-10 degrees, and mix by washing with water, Place it in a high temperature of 200-300 degrees for dehydration.

[0041] Put 5wt% of sodium metaaluminate and 3wt% of urea into the crucible at a high temperature of 600-1000 degrees for burning, and place it at room temperature to cool.

[0042] 70wt% alumina powder and 10wt% boehmite powder were mixed and stirred for 24 hours, placed in pure water for hydration soaking for 2 hours, and dehydrated at a low ...

Embodiment 3

[0045] Another optional embodiment of the present invention: a mixed amphoteric agent of alumina powder and boehmite, including 74wt% alumina powder, 8wt% boehmite powder, and 10wt% nicotinamide adenine Dinucleotide phosphate, 2wt% polyphenylene ether sulfone, 3wt% sodium metaaluminate and 3wt% urea.

[0046] Put 10wt% nicotinamide adenine dinucleotide phosphate and 2wt% polyphenylene ether sulfone into a hydrothermal reaction kettle, carry out a hydrothermal reaction for 30 minutes, and carry out low-temperature cooling at 0-10 degrees, and mix by washing with water, Place it in a high temperature of 200-300 degrees for dehydration.

[0047] Put 3wt% of sodium metaaluminate and 3wt% of urea into a crucible at a high temperature of 600-1000°C for burning, and place it at room temperature to cool.

[0048] 74wt% alumina powder and 8wt% boehmite powder were mixed and stirred for 24 hours, placed in pure water for hydration soaking for 2 hours, and dehydrated at a low temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com