Ventilation and heat dissipation device

A technology of ventilation and heat dissipation, fan, applied in the direction of cooling/ventilation/heating transformation, closed chassis, electrical components, etc., can solve the problems of high ventilation and ventilation cost, low ventilation and heat dissipation efficiency, unreasonable settings, etc., to reduce ventilation and heat dissipation. cost, improve the efficiency of ventilation and heat dissipation, and reduce the cost of ventilation and ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

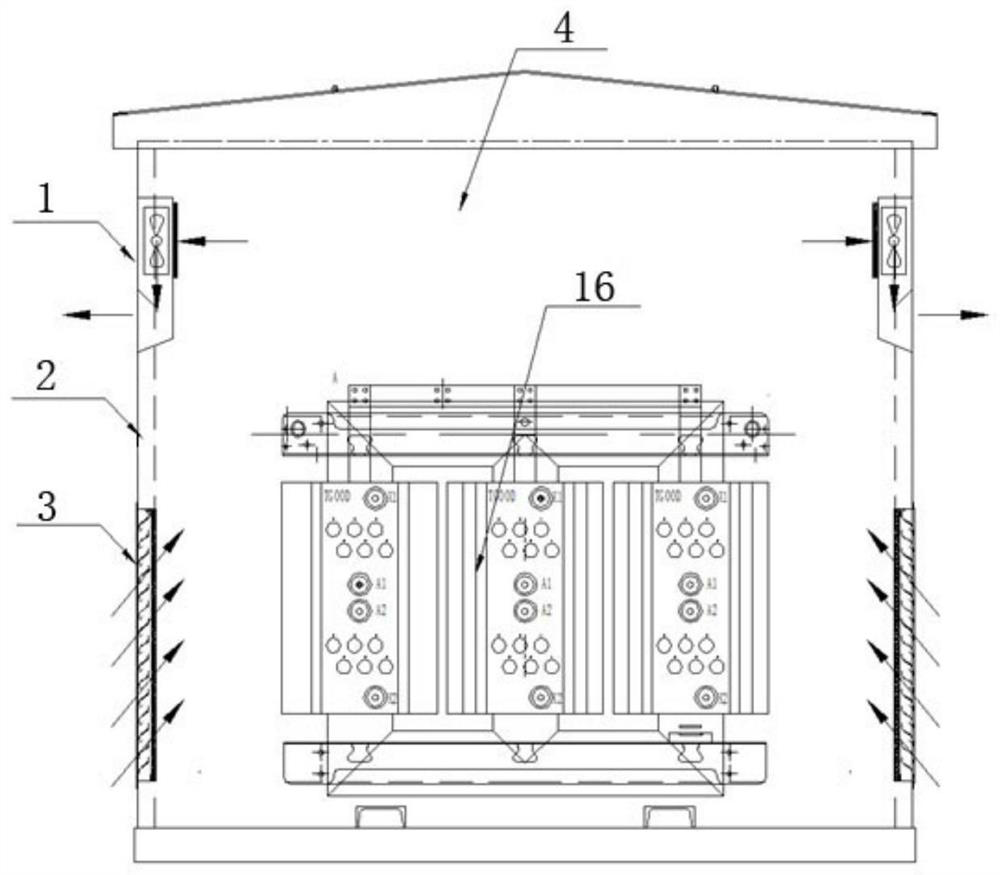

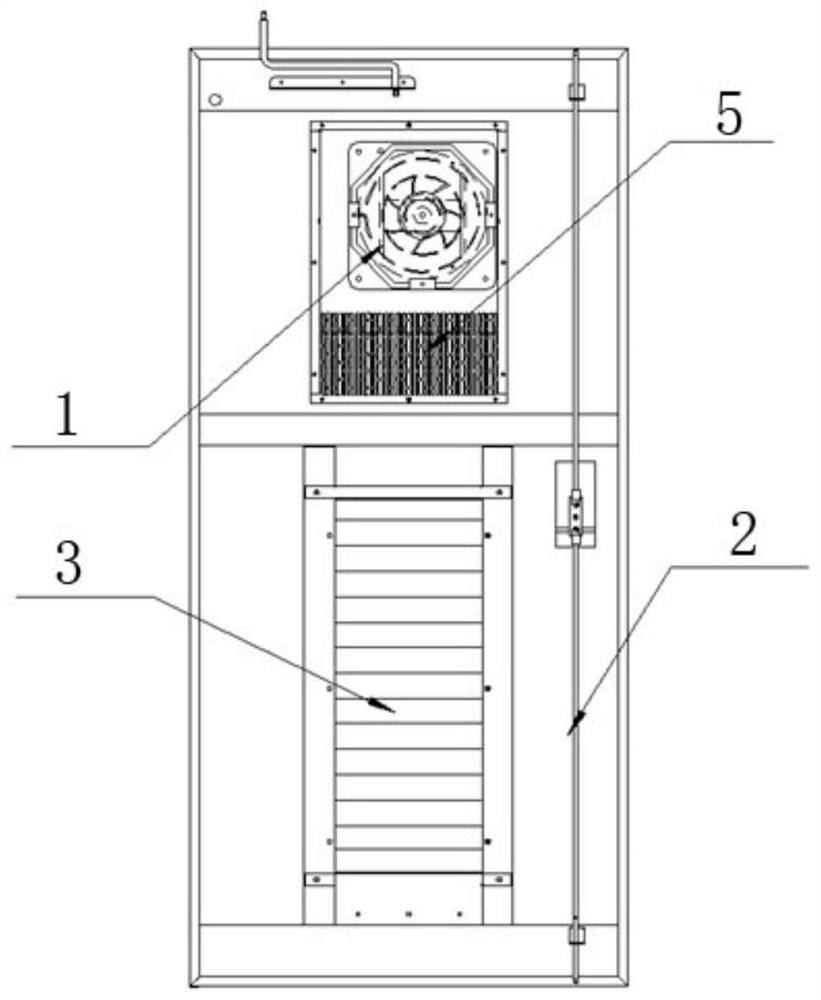

[0028] Embodiment 1 The ventilation and heat dissipation device provided by this embodiment, such as figure 1 and 2 As shown, it is installed inside the enclosure structure 4 of the power transformation and distribution equipment, and is mainly composed of a volute assembly 1 , a panel assembly 2 and an air intake assembly 3 . Wherein, both the volute assembly 1 and the air inlet assembly 3 are fixed on the panel assembly 2, and the volute assembly 1 and the air inlet assembly 3 can be on the same panel or on opposite panels, which need to be determined according to actual needs.

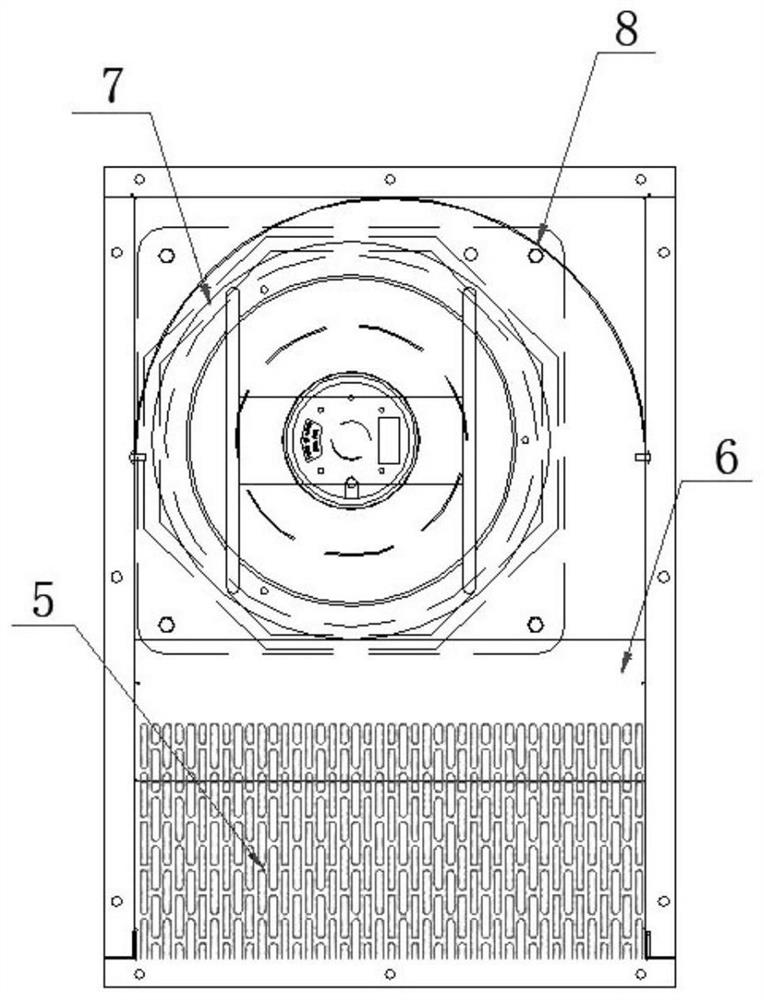

[0029] Such as image 3 and Figure 4 As shown, the volute assembly 1 is composed of a volute 6, a fan assembly, an arc deflector 8, and a filter 9. The fan assembly is fixed to the upper part of the volute 6 by fasteners, and the arc-shaped wind deflector 8 is a curved curved plate arranged above the fan assembly, and its two sides are fixed on the inner wall of the volute 6 . The arc-shaped wi...

Embodiment 2

[0033] Embodiment 2 The ventilation and heat dissipation device provided by this embodiment, such as Figure 8 As shown, it mainly includes a volute assembly 1 installed on the outer facade of the enclosure structure 2 . Among them, the enclosure structure 2 is an infrastructure for ventilation applications, and its function is to install fixed ventilation devices or equipment to provide support for ventilation equipment. The volute assembly 1 is fixedly installed on the enclosure structure 2 through the flexible seal 3, which increases tightness and improves the protection level of the enclosure structure.

[0034] Such as Figure 9 and 10 As shown, the volute assembly 1 mainly includes a fan assembly, a volute 5 and a filter 6 .

[0035] Wherein the volute 5 is covered outside the front side of the fan assembly. An air outlet 7 is provided at the bottom of the volute 5 . Such as Figure 11 As shown, the fan assembly is composed of a fan 4, an air guide ring 11, and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com