Shell-and-tube point discharge solid-liquid phase change enhanced heat transfer device based on electrofluid mechanics

A cutting-edge discharge and solid-liquid phase change technology, applied in heat storage equipment, tubular elements, indirect heat exchangers, etc., can solve problems such as the inability to adjust the speed of the phase change process, and achieve the effect of small additional power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

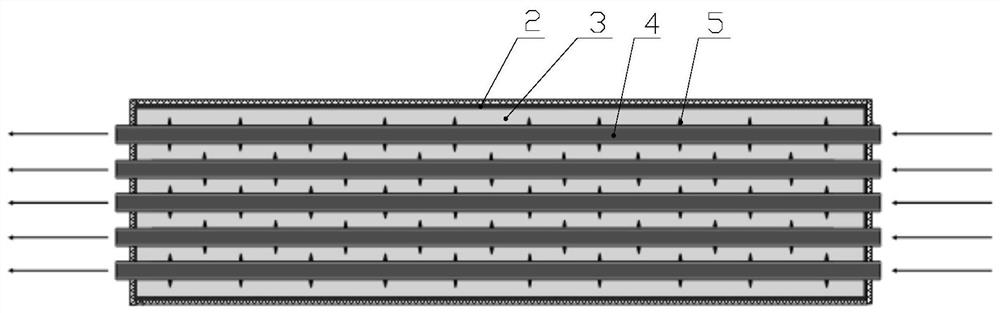

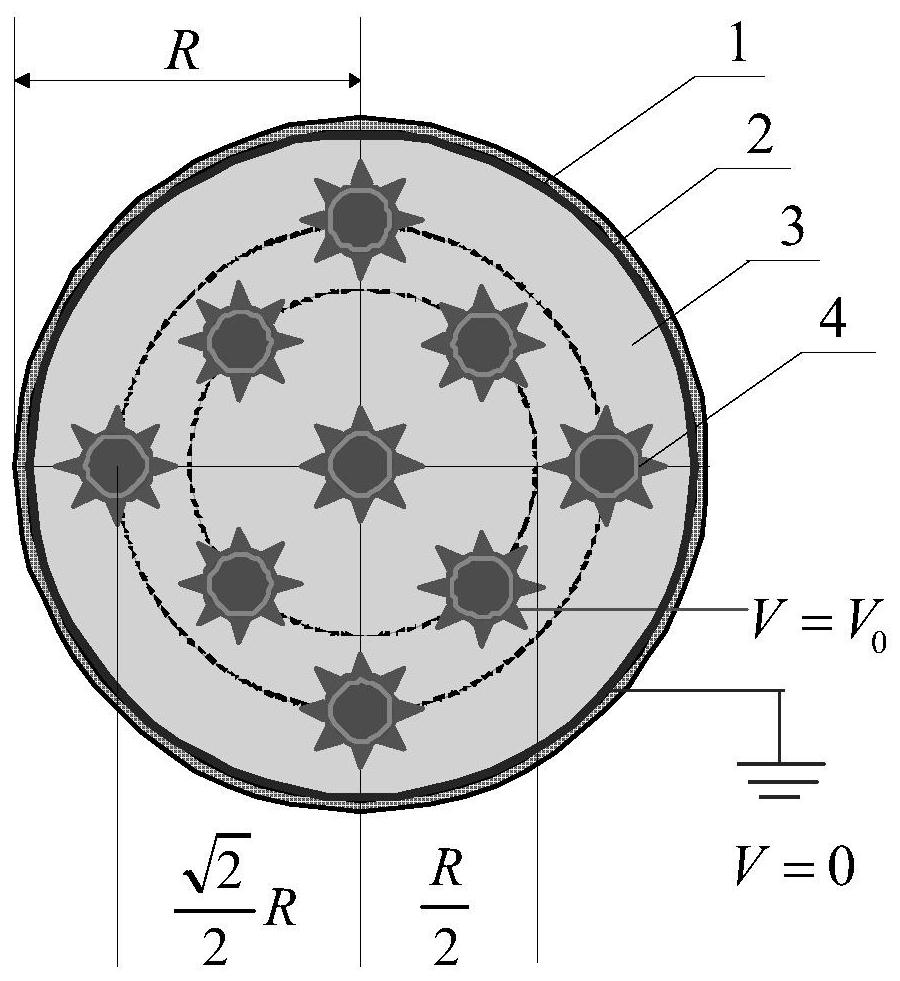

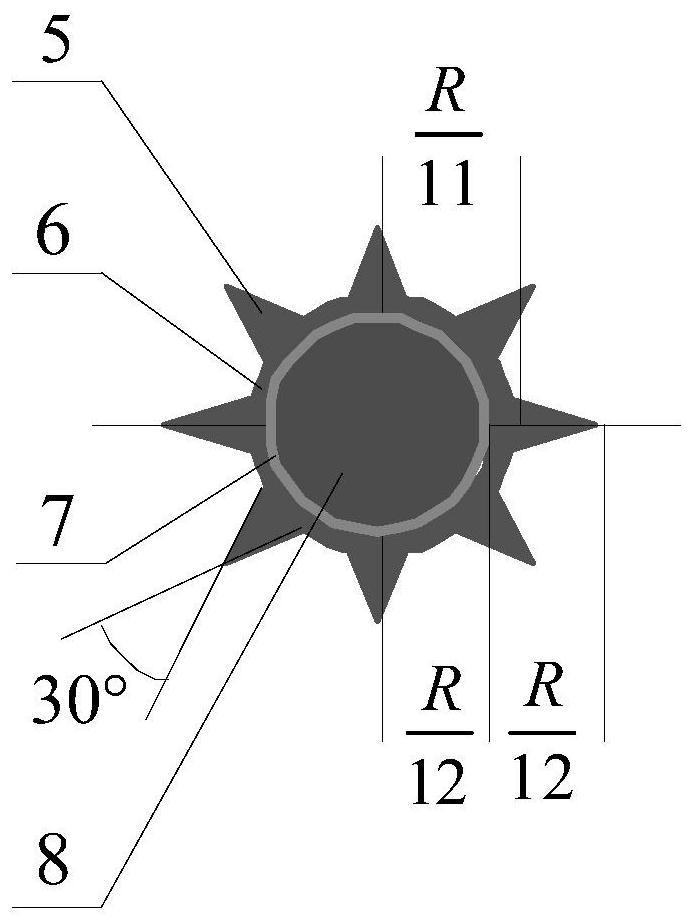

[0022] Specific implementation mode one: combine Figure 1~3 Describe this embodiment, based on the shell-and-tube type tip discharge solid-liquid phase change enhanced heat transfer device based on electrohydrodynamics, it includes a metal outer tube 2 and a number of composite inner tubes 4 arranged in the metal outer tube 2, and the metal outer tube 2 The phase change material 3 is filled with the composite inner tube 4, the metal outer tube 2 is grounded and its outer wall is provided with a heat insulating layer 1, and the composite inner tube 4 includes a metal inner tube 6, several groups arranged outside the metal inner tube 6 The fins and the insulating layer 7 arranged on the inner wall of the metal inner tube 6 are connected to a direct current positive voltage, and a heat source 8 is circulated inside the metal inner tube 6 .

[0023] The composite inner tube 4 is an anode, which is connected to a positive DC voltage; the metal outer tube 2 is a cathode, and is gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com