Safe degassing kettle for grease processing

A technology of oil processing and degassing kettle, which is applied in the field of oil processing, and can solve the problems of processing operations that affect the degassing quality of oil material liquid, low practicability, and slow output viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

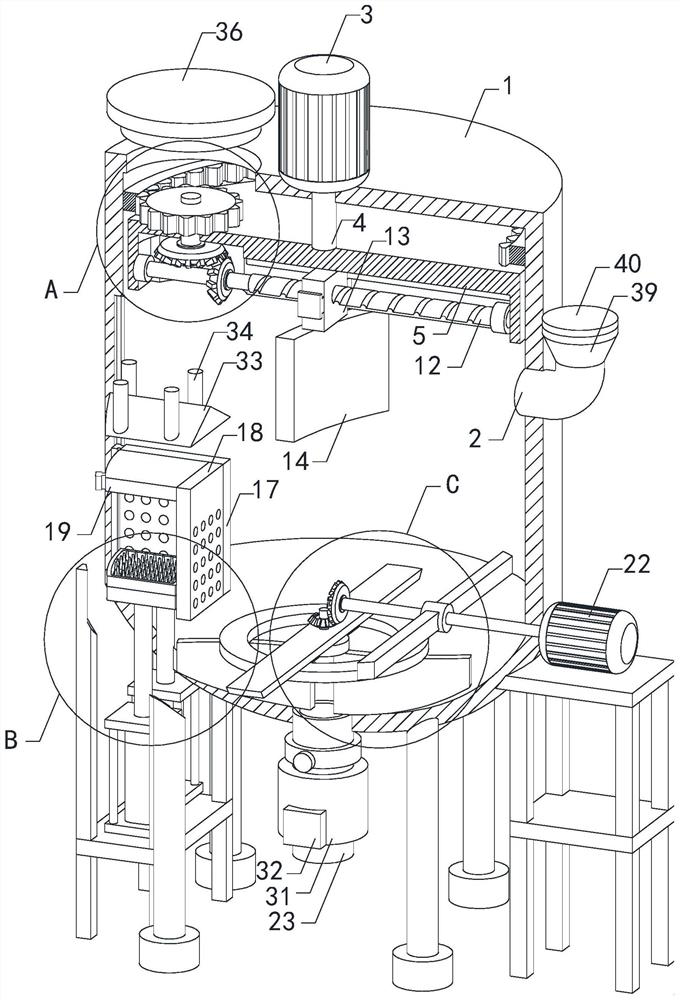

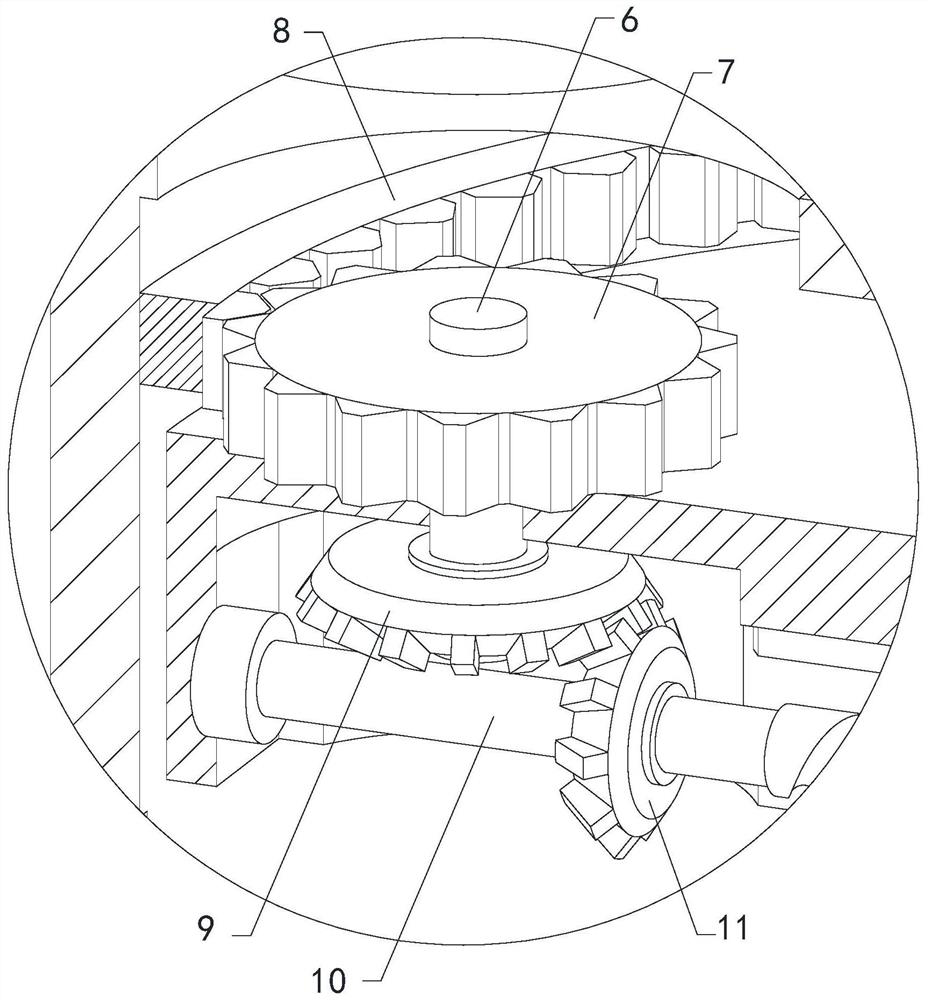

[0031] see Figure 1-6, a safe degasser for oil processing, including a degasser body 1, also includes a bubble treatment device and a material discharge auxiliary device, the side wall of the degasser body 1 is connected with a feed pipe 2, and the feed pipe 2 is connected with a feed hopper 39, and the feed hopper 39 is connected with a cover 40, which is convenient to cover the feed pipe 2 and the feed hopper 39, and reduces the feed pipe 2 and the feed hopper 39 when they are idle. The sundries falling into the degasser body 1 in the pipe 2 and the feed hopper 39, the bubble treatment device includes a bubble concentration mechanism and a processing mechanism, the bubble concentration mechanism includes a first motor 3, and the first motor 3 is fixedly installed in the degasser The top of the body 1 and the bottom output end of the first motor 3 are fixedly connected with the first rotating shaft 4, and the bottom end of the first rotating shaft 4 penetrates the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com