Self-adhesive waterproof coiled material and production process thereof

A waterproof membrane, self-adhesive technology, applied in the direction of adhesive type, adhesive, other rubber adhesives, etc., can solve the problems of lack of heat insulation performance, waterproof membrane not resistant to high temperature, difficult maintenance, etc. Achieve the effects of improving the bonding effect and high temperature resistance, aging resistance and vulcanization speed, and chemical inactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The self-adhesive waterproof membrane of the present invention is prepared from the following components by weight:

[0021] Asphalt 4000kg, rubber oil 1200kg, styrene-based thermoplastic elastomer 400kg, styrene-butadiene rubber 200kg, tire rubber powder 1350kg, talcum powder 2850kg, polyester tire 200g.

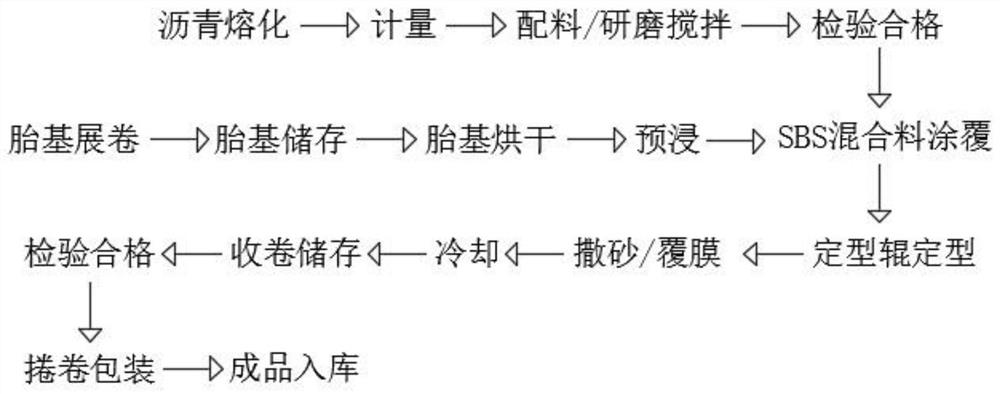

[0022] The first step: melt the asphalt first, then weigh and measure it, and take 4000kg;

[0023] The second part: Then weigh 1200kg of rubber oil, 400kg of styrene-based thermoplastic elastomer, 200kg of styrene-butadiene rubber, 1350kg of tire rubber powder, and 2850kg of talcum powder, and then grind and stir the weighed materials with molten asphalt, and finally get SBS mixture, and then inspect the SBS mixture obtained by stirring;

[0024] Step 3: Unroll the polyester tire at the same time, and then store the polyester tire;

[0025] Step 4: Then dry the polyester tire, and then prepreg the polyester tire;

[0026] The fifth step: coating the SBS mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com