Preparation method of shaped antibacterial face sealing cover material for protective mask

A technology of sealing cover and face, applied in protective clothing, application, clothing, etc., can solve the problem that the actual effect is very different, and achieve the effect of improving scorch condition, high mechanical strength, and avoiding air leakage through the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

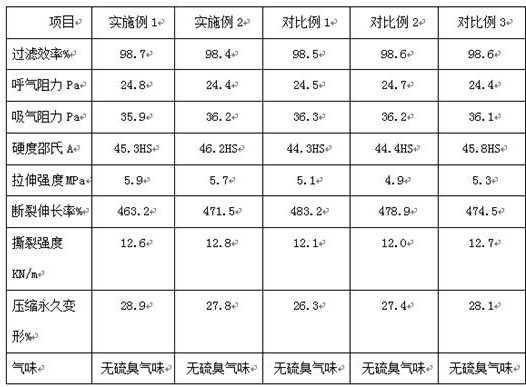

Examples

Embodiment 1

[0017] (1) In parts by weight, 40 parts of fumed white carbon black, dihydroxy polydimethylsiloxane, 8 parts of vinyl tributylketoxime silane, 25 parts of N-(β-aminoethyl) - 8 parts of γ-aminopropyltrimethoxysilane, 90 parts of raw methyl vinyl silicone rubber, kneading in a high-speed mixer at 60°C for 1 hour to form a base material; (2) 90 parts of the prepared base material, 4 parts of dimethyl azobisisobutyrate and 0.6 part of dicumyl peroxide were mixed on a double-roll machine at 120°C, and then 23 parts of supported catalyst white carbon black and 0.05 part of 1-ethynyl cyclohexanol were added. The rubber raw material was masticated in an internal mixer for 2 minutes, and then added 25 parts of eucommia gum, 5 parts of zinc oxide, 1.0 part of stearic acid, 1.5 parts of anti-aging agent, 1.0 part of accelerator, 2.0 parts of three Allyl isocyanurate is mixed for 2 minutes and then heated for 120 seconds. When the mixing temperature reaches 160°C, the glue is discharged, ...

Embodiment 2

[0019](1) In parts by weight, 30 parts of vinyl tributylketoxime silane, 11 parts of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, methyl vinyl silicone rubber 100 parts of glue, 45 parts of fumed white carbon black, 10 parts of dihydroxypolydimethylsiloxane, mixed in a high-speed mixer at 70°C for 2 hours to prepare the base material; (2) 100 parts of the prepared base material, 4 parts of dimethyl azobisisobutyrate and 0.6 part of dicumyl peroxide were mixed on a double-roller machine at 120°C, and then 25 parts of supported catalyst white carbon black and 0.05 part of 1-ethynyl cyclohexanol were added. The rubber raw material was masticated for 2 minutes in an internal mixer, and then 5 parts of zinc oxide, 1.0 part of stearic acid, 1.5 parts of anti-aging agent, 25 parts of Eucommia gum, 1.0 part of accelerator, 2.0 parts of three Allyl isocyanurate is mixed for 2 minutes and then heated for 120 seconds. When the mixing temperature reaches 160°C, the glue is discharged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com