Macromolecular flame retardant, preparation method and application thereof

A polymer flame retardant and flame retardant technology, applied in the polymer field, can solve the problems of easy hydrolysis, easy migration, and inability to realize environmental protection and flame retardancy, and achieve the effect of good flame retardancy and light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

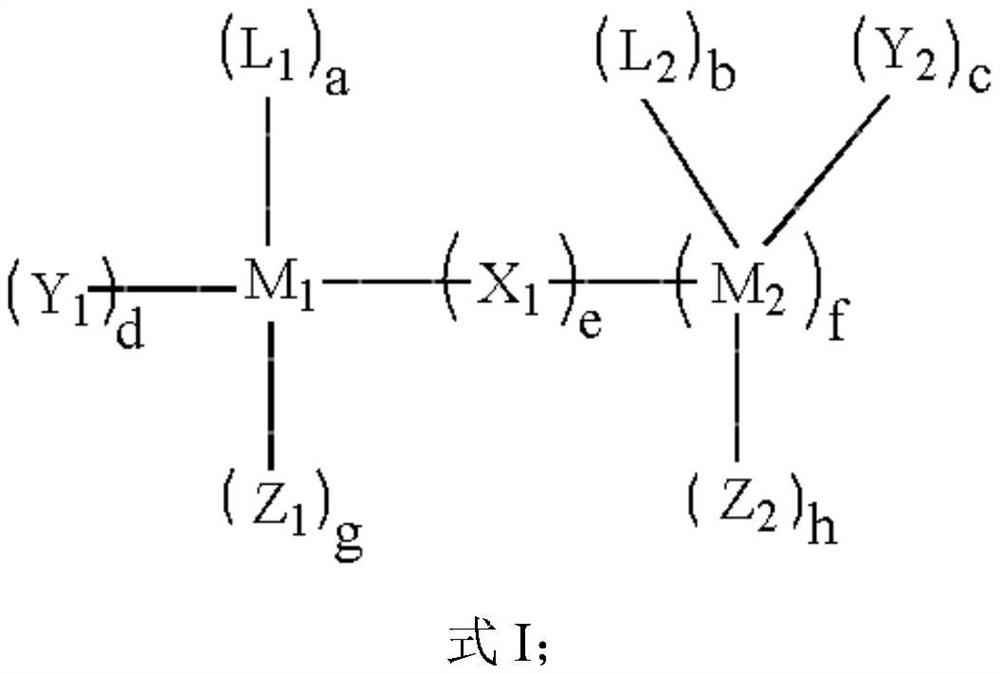

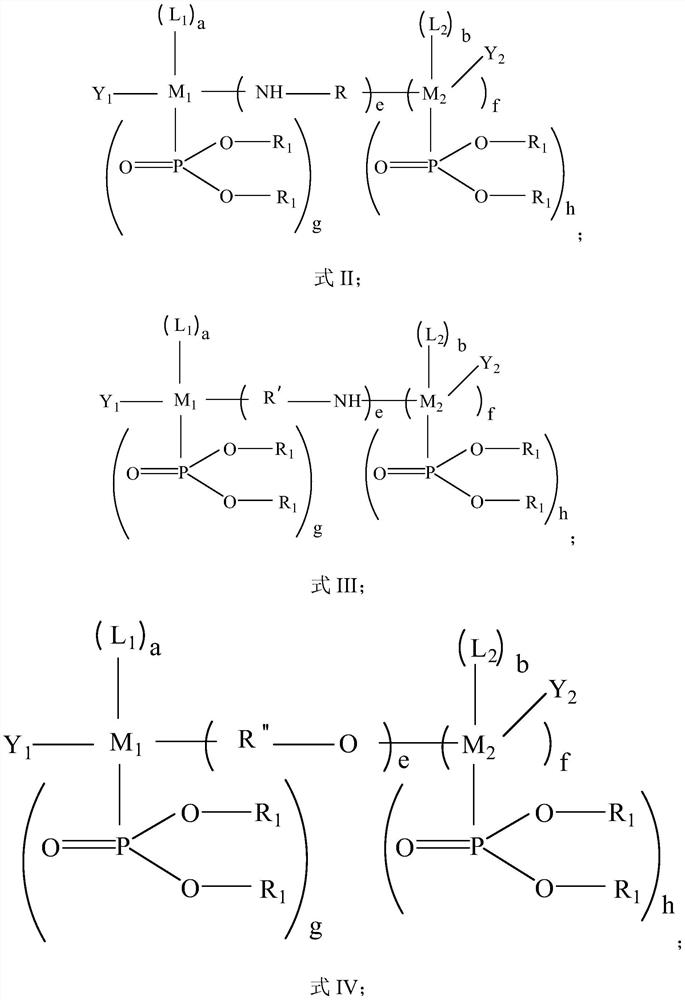

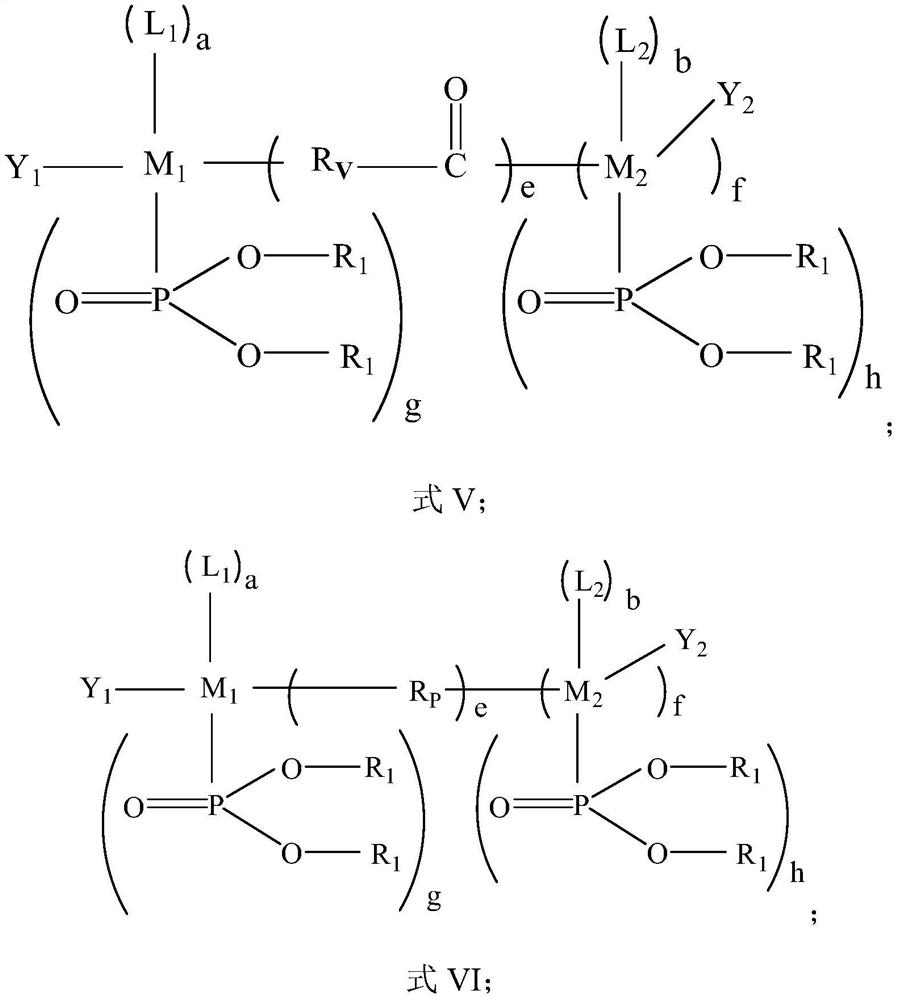

Method used

Image

Examples

preparation example 1

[0089] A phosphorus-containing flame retardant with a vinyl group, the structure is as follows:

[0090]

[0091](1) Add 2,2,6,6-tetramethylpiperidinamine (15.6g) and dichloromethane (200mL) into a 100mL two-necked flask equipped with a thermometer, stir, and place in an ice bath to cool to 0°C , slowly added a solution of acryloyl chloride (purity 95%, 9.1g) in dichloromethane (20mL), reacted at 0°C for 30min, and then isolated the product;

[0092] (2) 1 mol of the product obtained in step (1) and 1 mol of dimethyl hydroxymethyl phosphite, 100 mL of ethanol, 0.1 mol of sodium hydroxide, and 0.1 g of DMAP are heated to reflux of ethanol, reacted for 3 h, and then added hydrochloric acid until the pH is 7. Remove impurities to obtain the phosphorus-containing flame retardant with the above structure.

[0093] 1 H NMR (CDCl 3 ,400MHz,TMS):δ=7.98(s,1H,-NH-),6.48-6.60(dd,1H,-CH=),6.00-6.20(d,1H,-CH=),5.70-5.80(d ,1H,-CH=),3.66-3.80(s,6H,-O-CH 3 ),3.50-3.60(m,1H,-NH-C H -...

preparation example 2

[0095] A phosphorus-containing flame retardant with a vinyl group, the structure is as follows:

[0096]

[0097] (1) Add 2,2,6,6-tetramethylpiperidinamine (15.6g) and dichloromethane (200mL) into a 100mL two-necked flask equipped with a thermometer, stir, and place in an ice bath to cool to 0°C , slowly add a solution of methacryloyl chloride (purity 95%, 10.5g) in dichloromethane (20mL), react at 0°C for 30min, and then isolate the product;

[0098] (2) 1 mol of the product obtained in step (1) and 1 mol of dimethyl hydroxymethyl phosphite, 100 mL of ethanol, 0.1 mol of sodium hydroxide, and 0.1 g of DMAP are heated to reflux of ethanol, reacted for 3 h, and then added hydrochloric acid until the pH is 7. Remove impurities to obtain the phosphorus-containing flame retardant with the above structure.

[0099] 1 H NMR (CDCl 3 ,400MHz,TMS):δ=8.22(s,1H,-NH-),5.70-5.80(d,2H,CH 2 =),3.60-3.80(s,6H,-O-CH 3 ),3.50-3.60(m,1H,-NH-C H -),2.80-2.90(d,2H,-P-C H 2 -),2.02(s,3H,...

preparation example 3

[0101] A phosphorus-containing flame retardant with a vinyl group, the structure is as follows:

[0102]

[0103] The preparation method is as follows:

[0104] Add 1 mol of diethyl phosphite and 1 mol of acrolein into a three-necked flask equipped with magnetic stirring and a thermometer. Under stirring, control the temperature in an ice-water bath below 5°C, add 1 mol of triethylamine dropwise, gradually raise the temperature to 50°C, and continue After reacting for 0.5h, the phosphorus-containing flame retardant of the above structure was obtained by distillation under reduced pressure.

[0105] 1 H NMR (400MHz, DMSO-d6): δ=5.86-5.90(m,1H,=CH-), 5.27-5.39(m,2H,CH 2 =),5.10-5.12(m,1H,-OH),4.15-4.22(m,1H,-CH-),3.87-4.02(m,4H,-CH 2 -),1.24-1.28(t,6H,-CH 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com