N-caprylic acid diisopropanol amide, preparation method thereof and corrosion inhibitor

A technology of n-octanoic acid diisopropanolamide and diisopropanolamide, which is applied in the field of metal corrosion inhibition, can solve the problem that corrosion inhibitors cannot have both, and achieves the effects of good aluminum corrosion inhibition effect, low production cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the embodiment of the application is as follows:

[0037] (1) Put 17%~27wt.% n-octanoic acid into the reactor, heat up to 90°C, and set aside;

[0038] (2) 73%~83wt.% diisopropanolamine is slowly dropped into the reactor;

[0039] (3) Put 0.1-0.2wt.% of the catalyst 18-crown-6 into the reaction kettle, raise the temperature to 110-125°C, react at this temperature for about 4-5 hours, and simultaneously turn on the vacuum pump to discharge The water generated by the reaction was stopped heating when no more water was distilled out.

[0040] (4) naturally cool to room temperature, discharge, and make n-octanoic acid diisopropanolamide.

[0041] The CAS of the oleic acid diethanolamide used in Comparative Example 1 below is 93-83-4, and the chemical formula is: CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 C(=O)N(CH 2 CH 2 Oh) 2 . The tall oleic acid diethanolamide in Comparative Example 2 is tall oleic acid diethanolamide synthesized from tall oleic a...

Embodiment 1

[0043] The embodiment of the present application provides the preparation method of n-octanoic acid diisopropanolamide, specifically comprising:

[0044] (1) 23% n-octanoic acid is put into the reactor, and the temperature is raised to 90° C. for subsequent use;

[0045] (2) 77% diisopropanolamine is slowly dropped into the reactor;

[0046] (3) Put 0.1 to 0.2% of the catalyst 18-crown-6 into the reactor, raise the temperature to 118°C, and react at this temperature for about 4.5 hours. At the same time, turn on the vacuum pump to discharge the water generated by the reaction until there is no more Heating was stopped when the water distilled off.

[0047] (4) naturally cool to room temperature, discharge, namely n-octanoic acid diisopropanolamide as described in formula I.

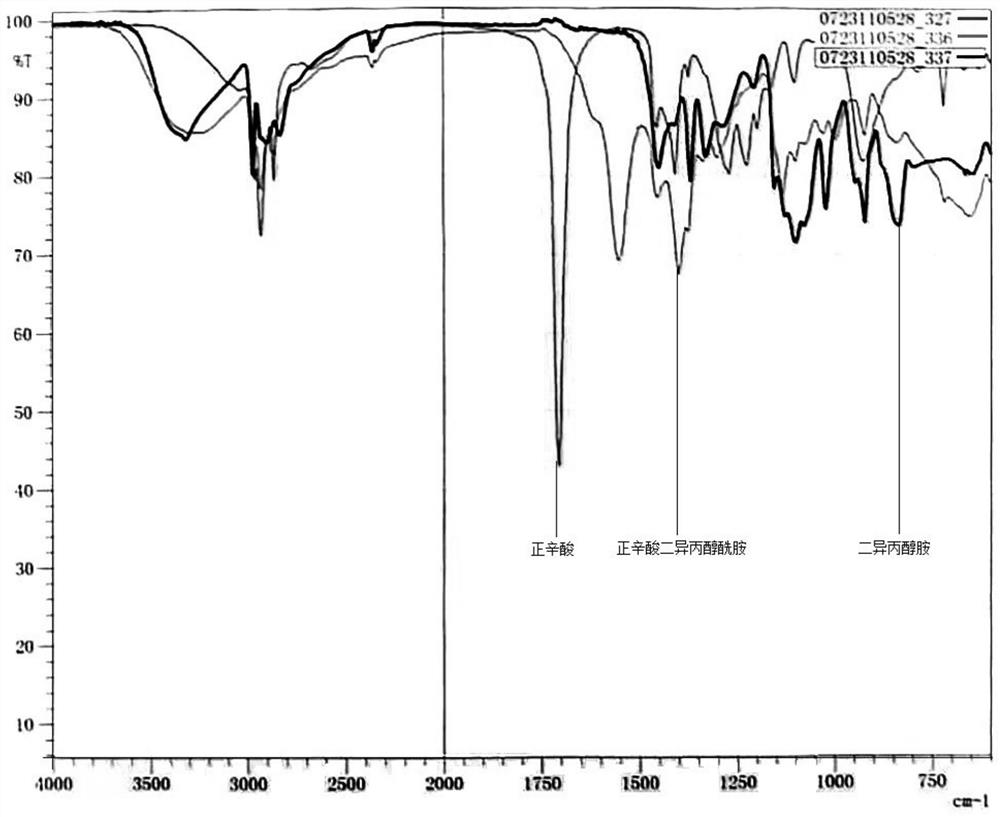

[0048] (5) The n-octanoic acid diisopropanolamide described in the embodiment of the present application is carried out infrared spectrum analysis and nuclear magnetic resonance spectrum analysis, the r...

Embodiment 2

[0050] The embodiment of the present application provides the corrosion inhibition performance test of the LY12 aluminum alloy of embodiment 1, comparative example 1, comparative example 2 and comparative example 3, and the specific steps are as follows:

[0051] With reference to the corrosion test method in "GB6144-2010 Synthetic Cutting Fluid", test example 1, comparative example 1 (oleic acid diethanolamide), comparative example 2 (tall oleic acid diethanolamide) and comparative example 3 (conventional non-foaming corrosion inhibitor sodium silicate) of LY12 aluminum alloy corrosion inhibition performance.

[0052] 1. Configure the working solution: respectively configure Example 1, Comparative Example 1, Comparative Example 2 and Comparative Example 3 into corresponding working solutions with concentrations of 0.05%, 0.1%, 0.2%, 0.5%, and 0.8%. The solute in the liquid is Example 1, Comparative Example 1, Comparative Example 2 and Comparative Example 3, and the solvent is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com