High-quality RH gunning mix added with large amount of cast iron powder and production method thereof

A technology of adding a large amount of cast iron powder, applied in the field of refractory materials for RH vacuum refining equipment in steelmaking plants, can solve the problems of failure to achieve gunning maintenance effect, erosion of RH dip tube, poor sintering effect, etc., and achieve high comprehensive utilization value. , The skeleton structure is uniform, and the effect of high-frequency continuous operation is satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

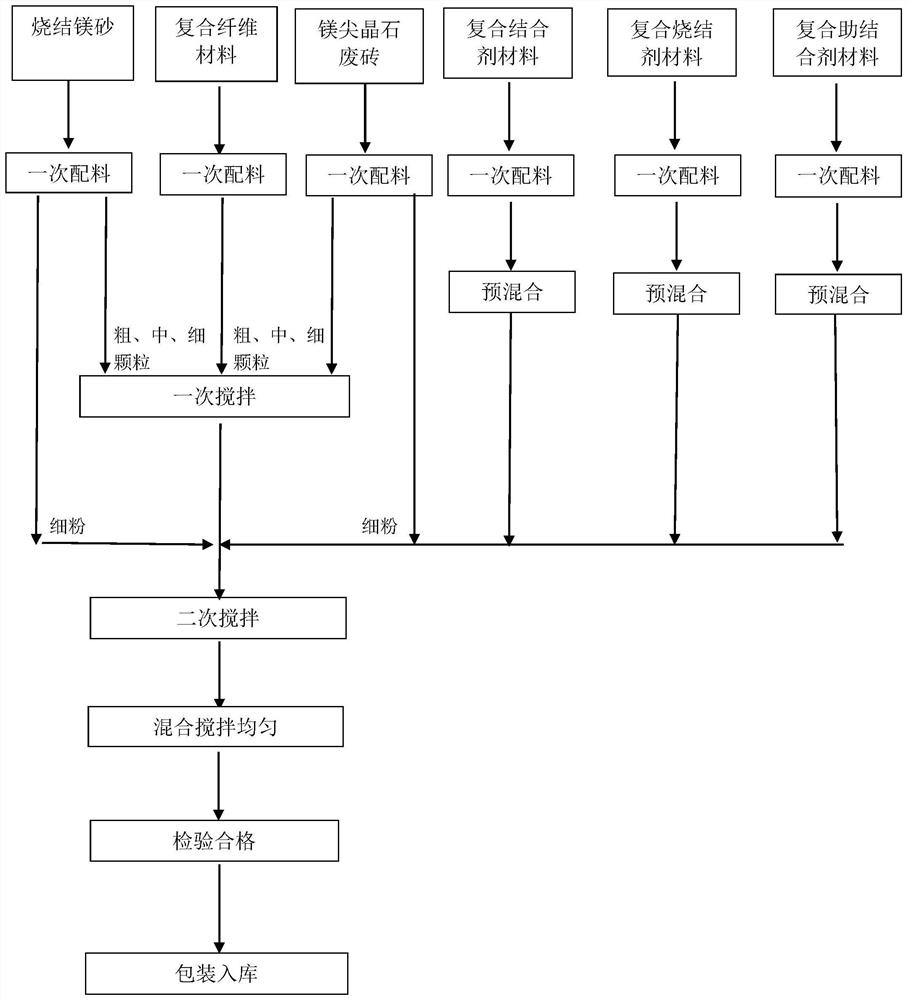

Method used

Image

Examples

Embodiment 1

[0034] A steel factory has two 130-ton electric furnaces and two 130-ton "three-vehicle and five-position" RH vacuum treatment tanks. The steel types include high-quality carbon structural steel, alloy structural steel, gear steel, bearing steel, and free-cutting non-quenched and tempered steel. , spring steel, high-pressure boiler and tube billet steel, anchor chain and mooring chain steel, cold pier steel, prestressed steel wire, steel strand and tool steel, etc.

[0035] The vacuum ratio of the steel grades in the steelmaking plant is ~90%. Except that some steel grades of the 200×200mm continuous casting machine are not vacuum treated, other steel grades of the continuous casting slab section are 100% vacuum treated.

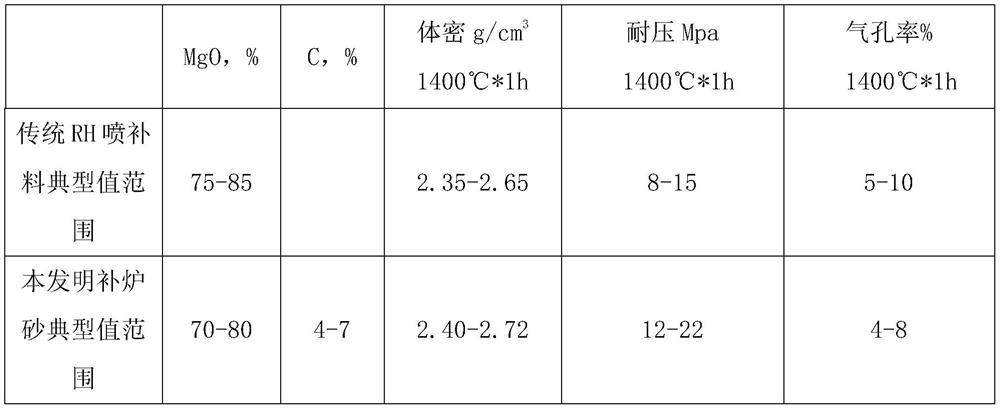

[0036] The material used for each gunning repair is 0.1-0.35 tons, the sintering time is required to be less than 10 minutes, and the service life is greater than 2 furnaces. Its production conditions are shown in Table 2.

[0037] Table 2: Example 1 Produc...

Embodiment 2

[0059] In a steel plant, the number of vacuum tanks: 10 (5 for 1#RH and 5 for 2#RH each); process flow: converter→LF→RH→casting machine, converter→RH→casting machine; the temperature of molten steel treated by RH is 1600-1650℃ , The treatment cycle is 35-55min. Other main process parameters are shown in Table 5.

[0060] Table 5: Example 2 Production Conditions

[0061]

[0062]

[0063] The material used for each gunning repair is 0.15-0.35 tons, the sintering time is required to be less than 12 minutes, and the service life is greater than 3 furnaces.

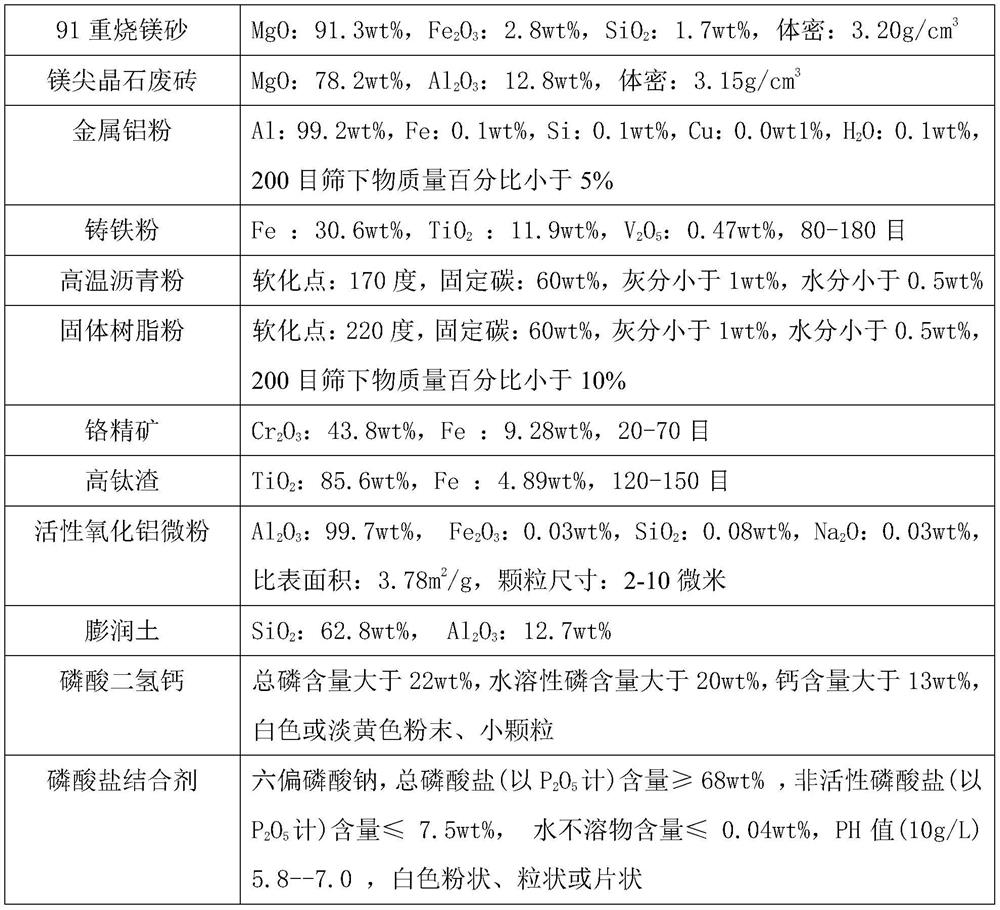

[0064] A high-quality RH gunning material with a large amount of cast iron powder added in the present invention is optimized according to the actual smelting requirements on site. The gunning material is specifically prepared from the following raw materials in parts by weight: 95 mid-grade magnesia: 45-55 parts , Magnesia spinel waste brick: 15-25 parts, composite binder: 12-16 parts, composite sintering agent: 6-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com