Iridium-based nanowire synthesis method

A synthesis method and nanowire technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of copper iridium nanowires with small diameter, difficult to promote, and poor universality , to achieve good universality, increase catalytic specific surface area, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

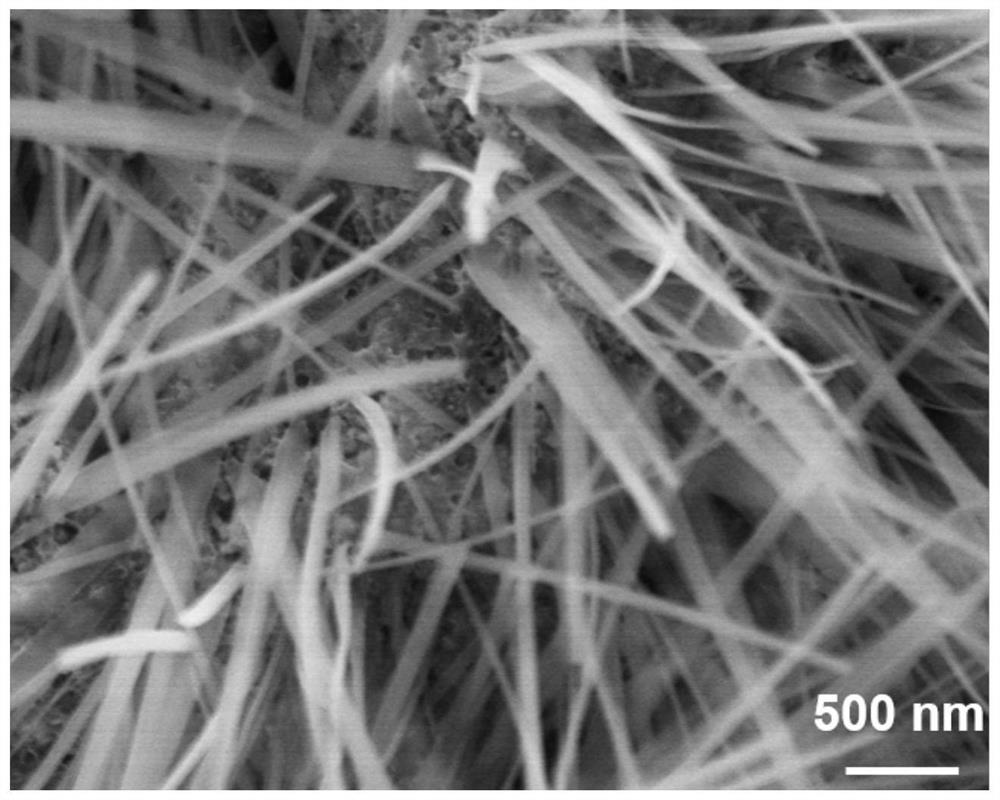

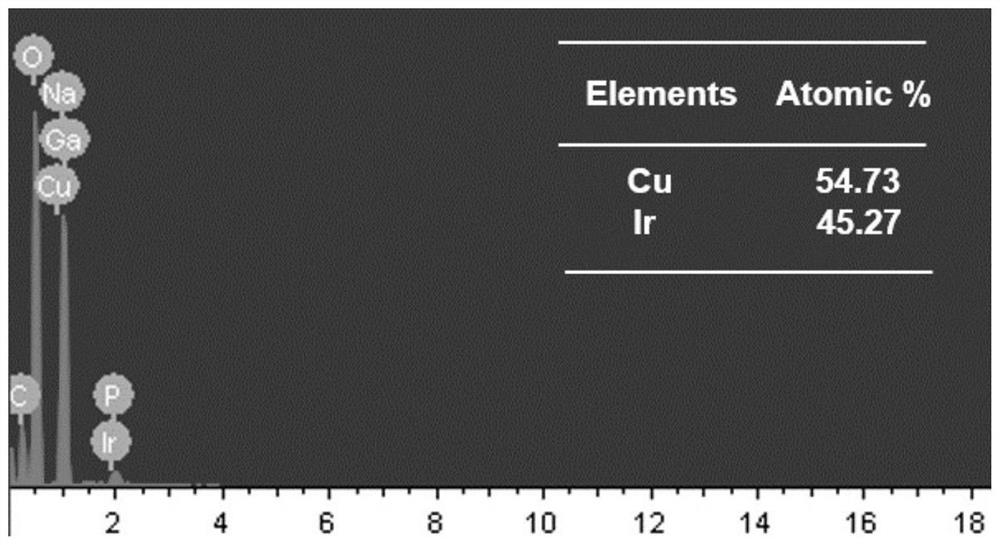

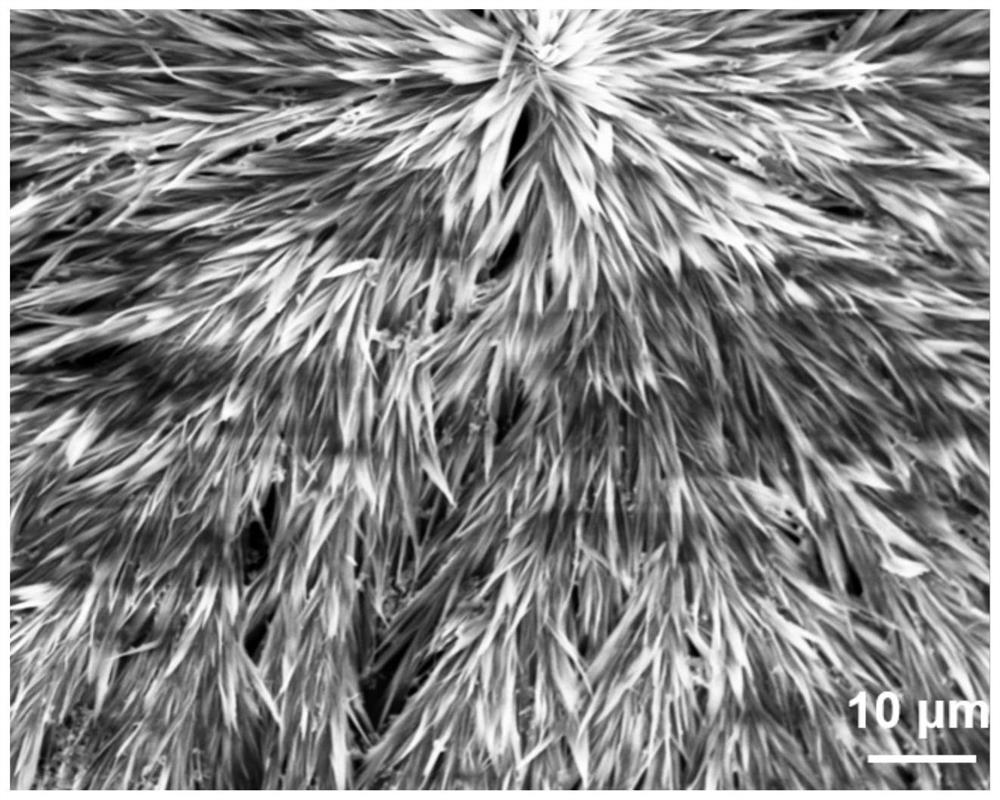

[0040] (1) Measure 6ml of dimethylformamide solution, 10mg of iridium trichloride, 10mg of copper trichloride dihydrate, and 40mg of polyvinylpyrrolidone (K30) into the same reactor, then weigh 2g of sodium iodide, super 2ml of pure water was mixed, and the two solutions were mixed and ultrasonicated for 30mins.

[0041] (2) Heat up the reaction system at 5°C / min for 30mins to 200°C, keep the temperature constant, and react for 5h to obtain a black solution. After the whole system is cooled, the product is centrifuged at 11000r / min for 20mins and washed with 8ml of ethanol 3 times, and finally dispersed in 1ml ethanol for later use to obtain iridium-copper alloy nanowires.

Embodiment 2

[0043] (1) Measure 6ml of dimethylformamide solution, 10mg of iridium trichloride, 10mg of silver acetate, and 40mg of polyvinylpyrrolidone (K30) into the same reactor, then weigh 2g of sodium iodide and 2ml of ultrapure water to mix , and then the two solutions were mixed and ultrasonicated for 30mins.

[0044] (2) Heat up the reaction system at 5°C / min for 30mins to 200°C, keep the temperature constant, and react for 5h to obtain a black solution. After the whole system is cooled, the product is centrifuged at 11000r / min for 20mins and washed with 8ml of ethanol 3 times, and finally dispersed in 1ml ethanol for later use to obtain iridium-silver alloy nanowires.

Embodiment 3

[0046] (1) Measure 6ml of dimethylformamide solution, 10mg of iridium trichloride, 10mg of palladium chloride, and 40mg of polyvinylpyrrolidone (K30) into the same reactor, then weigh 2g of sodium iodide and 2ml of ultrapure water After mixing, the two solutions were mixed and ultrasonicated for 30mins.

[0047](2) Heat up the reaction system at 5°C / min for 30mins to 200°C, keep the temperature constant, and react for 5h to obtain a black solution. After the whole system is cooled, the product is centrifuged at 11000r / min for 20mins and washed with 8ml of ethanol 3 times, and finally dispersed in 1ml ethanol for later use to obtain iridium-palladium alloy nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com