Low-temperature low-pressure direct hydrogenation catalyst for coal-based 1,4-butynediol and preparation method thereof

A technology of hydrogenation catalyst and butynediol, which is applied in the direction of catalyst activation/preparation, hydrogenation preparation, hydroxyl compound preparation, etc. It can solve the problems of removal, reduction, and impact, and achieve the effect of curbing conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

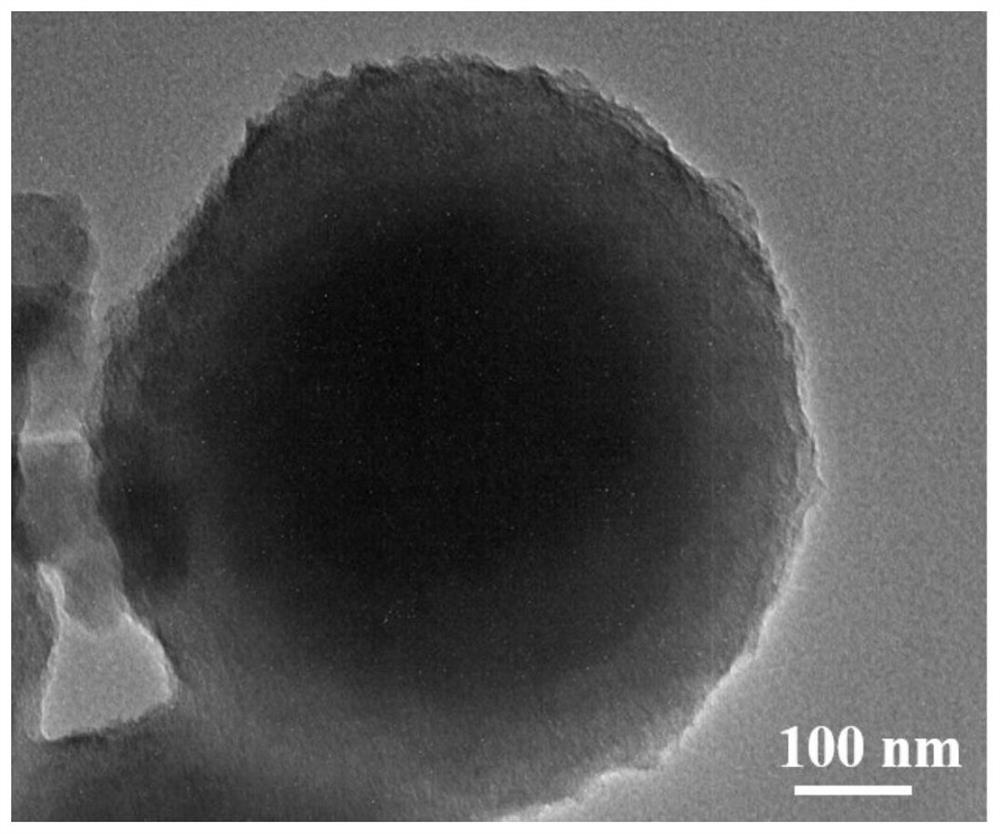

[0054] ① Prepare an ethanol-water solution with a volume ratio of ethanol:water of 0.5:1, and adjust the pH to 7.5 with ammonia water; raise the temperature to 60°C, slowly add 30mL / L methyl orthosilicate to the ethanol-water solution, and vigorously Stir for 1h, continue to add 27mL / L hexadecyltrimethoxysilane and 85mL / L methyl orthosilicate, and stir the mixed solution vigorously for 1h; after the above mixed solution is centrifugally filtered, wash with ethanol and deionized water respectively 3 times, the filtered item was dried at 90°C for 10 hours to obtain a uniformly layered coating structure SiO 2 @SiO 2 nanospheres.

[0055] ②Take 2.0g of prepared SiO 2 @SiO 2 Nanospheres were dispersed in 150 mL of water, and 0.005 mol of nickel acetylacetonate and 0.4 mol of urea were dissolved in it respectively, heated to 60°C, refluxed and stirred for 4 hours, then centrifugally filtered, washed with ethanol and deionized water for 5 times, and the filtered items were placed ...

Embodiment 2

[0058] ① Prepare an ethanol-water solution with a volume ratio of ethanol:water of 10:1, and adjust the pH to 8.5 with ammonia water; raise the temperature to 40°C, slowly add 80mL / L ethyl orthosilicate to the ethanol-water solution, and vigorously Stir for 2h, continue to add 22mL / L hexadecyltrimethoxysilane and 70mL / L ethyl orthosilicate, and stir the mixed solution vigorously for 1h; after the above mixed solution is centrifugally filtered, wash with ethanol and deionized water respectively 3 times, the filtered item was dried at 60°C for 8 hours to obtain a uniformly layered coating structure SiO 2 @SiO 2 nanospheres.

[0059] ②Take 2.0g of prepared SiO 2 @SiO 2 Disperse the nanospheres in 500mL water, and dissolve 0.006mol of nickel acetate and 0.2mol of urea in it respectively, raise the temperature to 120°C, reflux and stir for 2h, then centrifuge and filter, wash with ethanol and deionized water three times respectively, and filter the items at 100°C ℃ drying for 2...

Embodiment 3

[0062] ① Prepare an ethanol-water solution with a volume ratio of ethanol:water of 1:1, and adjust the pH to 9.0 with ammonia water; raise the temperature to 30°C, slowly add 40mL / L silica sol to the ethanol-water solution, and stir vigorously for 7 hours, Continue to add 30mL / L dodecyltrimethoxysilane and 100mL / L silica sol, and stir the mixed solution vigorously for 4h; after centrifuging and filtering the above mixed solution, wash with ethanol and deionized water for 3 times respectively, and filter the items in Dry at 125°C for 12 hours to obtain a uniformly layered coating structure SiO 2 @SiO 2 nanospheres.

[0063] ②Take 2.0g of prepared SiO 2 @SiO 2 Disperse the nanospheres in 300mL water, and dissolve 0.01mol of nickel acetate and 0.2mol of urea in it respectively, raise the temperature to 70°C, reflux and stir for 5h, then centrifuge and filter, wash with ethanol and deionized water for 5 times respectively, and filter the items at 80°C ℃ drying for 8 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com