Blueberry powder compound solid preparation capable of preventing and improving Alzheimer's disease as well as preparation method and application of blueberry powder compound solid preparation

A kind of Alzheimer's disease, solid preparation technology, applied in the direction of application, food ingredients as taste improvers, medical preparations containing active ingredients, etc., can solve the problems of uncertain curative effect, large toxic and side effects, muscle cramps, etc., and achieve prevention and treatment Improving the effect of dementia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

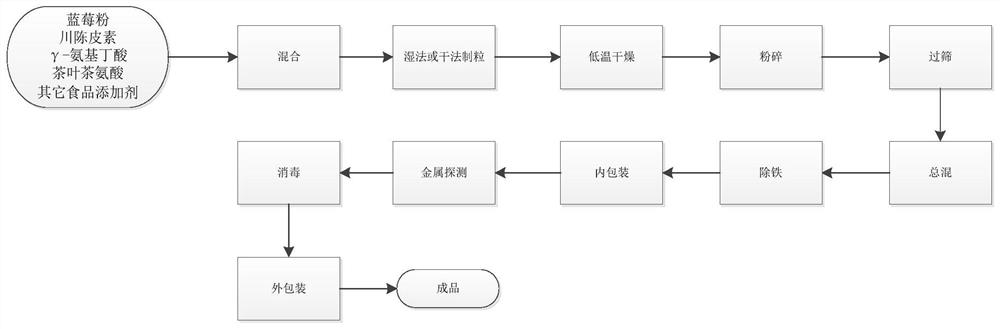

[0040] First, 80 parts by weight of blueberry powder, 50 parts of nobiletin, 35 parts of γ-aminobutyric acid and 35 parts of tea theanine were weighed, put into a mixing container and mixed evenly to obtain a mixed powder. Next, the obtained mixed powder is subjected to wet granulation or dry granulation and sizing, and the sizing size is 10 mesh to obtain mixed granules. Subsequently, the obtained mixed particles are dried at a low temperature below 50° C., pulverized and sieved, and the sieve mesh is 120 mesh to obtain a sieved powder. Finally, the metal foreign matter in the obtained sieved powder is removed by the iron remover, and then the metal detection inspection is carried out after the inner packaging is carried out in a food-grade or pharmaceutical-grade PE bag, and then the ultra-high pressure disinfection method is used for disinfection, and the outer packaging is carried out. to get the finished product.

[0041] Among them, the blueberry powder is made of wild ...

Embodiment 2

[0045] Weigh 40 parts of blueberry powder, 15 parts of nobiletin, 20 parts of γ-aminobutyric acid and 20 parts of tea theanine.

[0046] The sieving mesh is 100 mesh, and the disinfection method is hot water pasteurization, and the others are the same as in Embodiment 1.

[0047] The finished product obtained in the above steps can be used as a raw material, and can be prepared into common food, health food or medicine after appropriate addition of auxiliary materials such as food additives and auxiliary agents.

[0048] For example, add 16.8 parts by weight of purified water into a hot water heating jacketed stirring tank and heat it to 50°C, add 37 parts by weight of glycerin fatty acid ester, 68 parts of sunflower Seed oil and 100 parts of krill oil are put into this tank after mixing evenly and continue to stir, then add gelatin with a weight ratio of 141.02 parts, after the gelatin is completely dissolved, continue to put in a weight ratio of 52.18 parts of glycerin, and ...

Embodiment 3

[0050] Weigh 60 parts of blueberry powder, 50 parts of nobiletin, 30 parts of γ-aminobutyric acid and 60 parts of tea theanine.

[0051] The sieving mesh number is 80 orders, and others are the same as embodiment one.

[0052] The finished product obtained in the above steps can be used as a raw material, and can be prepared into common food, health food or medicine after appropriate addition of auxiliary materials such as food additives and auxiliary agents.

[0053] For example, add 1200 parts by weight of purified water to a hot water heating jacketed stirring tank and heat it to 38°C, add 30 parts by weight of modified soybean lecithin and 15 parts of alginic acid to the finished blueberry powder compound solid preparation Potassium, after being mixed evenly, drop into this tank and continue to stir, then weigh 120 parts by weight of non-energy sweetener, 50 parts of citric acid and 50 parts of L-malic acid, and use 500 parts by weight together The purified water is disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com