Composite air suction element, preparation method thereof and anti-flatulence self-repairing soft package lithium battery

A soft-packed lithium battery and component technology, applied in electrical components, battery pack components, circuits, etc., can solve problems such as lithium batteries prone to bulge, improve production efficiency and resource utilization, reduce scrap ratio, and improve battery safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

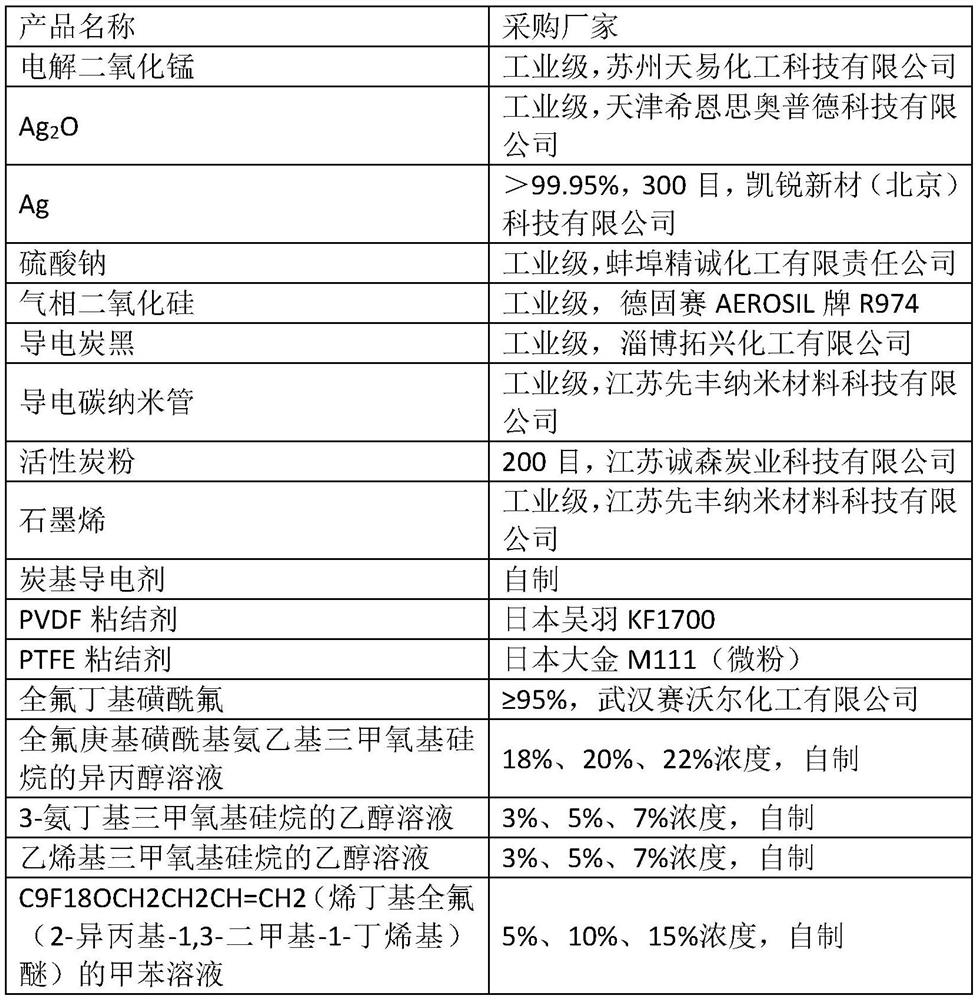

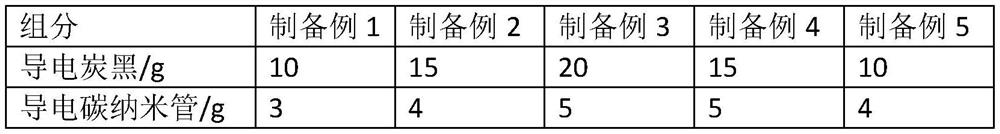

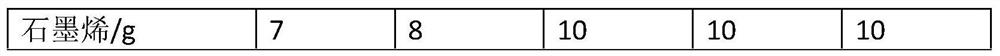

[0061] Preparation example of carbon-based conductive agent

[0062] Take the powder of conductive carbon black, conductive carbon nanotubes and graphene and put it into a mixer and mix for 20-30 minutes. After sieving, a carbon-based conductive agent with uniform composition is obtained. The particle size of the carbon-based conductive agent does not exceed . The composition of the carbon-based conductive agent is shown in Table 1.

[0063] Table 1 Raw material components prepared by carbon-based conductive agent

[0064]

[0065]

Embodiment 1

[0068] A preparation method of a composite getter element, comprising the following steps:

[0069] S1: 50g of electrolyzed MnO 2 , 10g of Ag 2 0, 4.5g carbon-based conductive agent, 15g activated carbon powder mix and grind 30min, particle size is 100-200nm, then be dispersed in 400ml alcohol and be mixed with slurry, carbon-based conductive agent is the carbon-based conductive agent of preparation example 1 , Alcohol use 95% alcohol.

[0070] S2: Add 14g of PVDF binder, 3g of sodium sulfate and 6.5g of gas-phase SiO to the slurry obtained in step S1 2 Mix uniformly to prepare a suspension, and ultrasonically treat the suspension for 3 minutes, then cast and shape it, and perform dynamic vacuum drying at 25°C for 48 hours to obtain a getter precursor. In other embodiments, the PVDF binder can also be replaced with a PTFE binder.

[0071] S3: Immerse the getter precursor in 20% perfluoroheptylsulfonylaminoethyltrimethoxysilane isopropanol solution, place it at 25°C for 24 ...

Embodiment 2

[0073] A preparation method of a composite getter element, comprising the following steps:

[0074] S1: 50g of electrolyzed MnO 2 , 10g of Ag 2 0, 4.5g carbon-based conductive agent, 13g activated carbon powder mix and grind 30min, particle size is 100-200nm, then be dispersed in 370ml alcohol and be mixed with slurry, carbon-based conductive agent is the carbon-based conductive agent of preparation example 1 , Alcohol use 95% alcohol.

[0075] S2: Add 13g of PVDF binder, 5g of sodium sulfate and 6.5g of gas-phase SiO to the slurry obtained in step S1 2 Mix uniformly to prepare a suspension, and ultrasonically treat the suspension for 2 minutes, then cast and shape it, and perform dynamic vacuum drying at 20°C for 50 hours to obtain a getter precursor.

[0076] S3: Immerse the getter precursor in the isopropanol solution of 18% perfluoroheptylsulfonylaminoethyltrimethoxysilane, put it at 20°C for 24 hours, take out the getter precursor, wash it and dry it. Get the compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com