Ceramic chip substrate for microwave integrated circuit and manufacturing method thereof

A microwave integrated circuit and manufacturing method technology, applied in circuits, electrical components, electrical solid devices and other directions, can solve the problems of uneven pads, uneven chip mounting, large grounding resistance, etc., and achieve high chip mounting density, satisfying Heat dissipation requirements and good process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

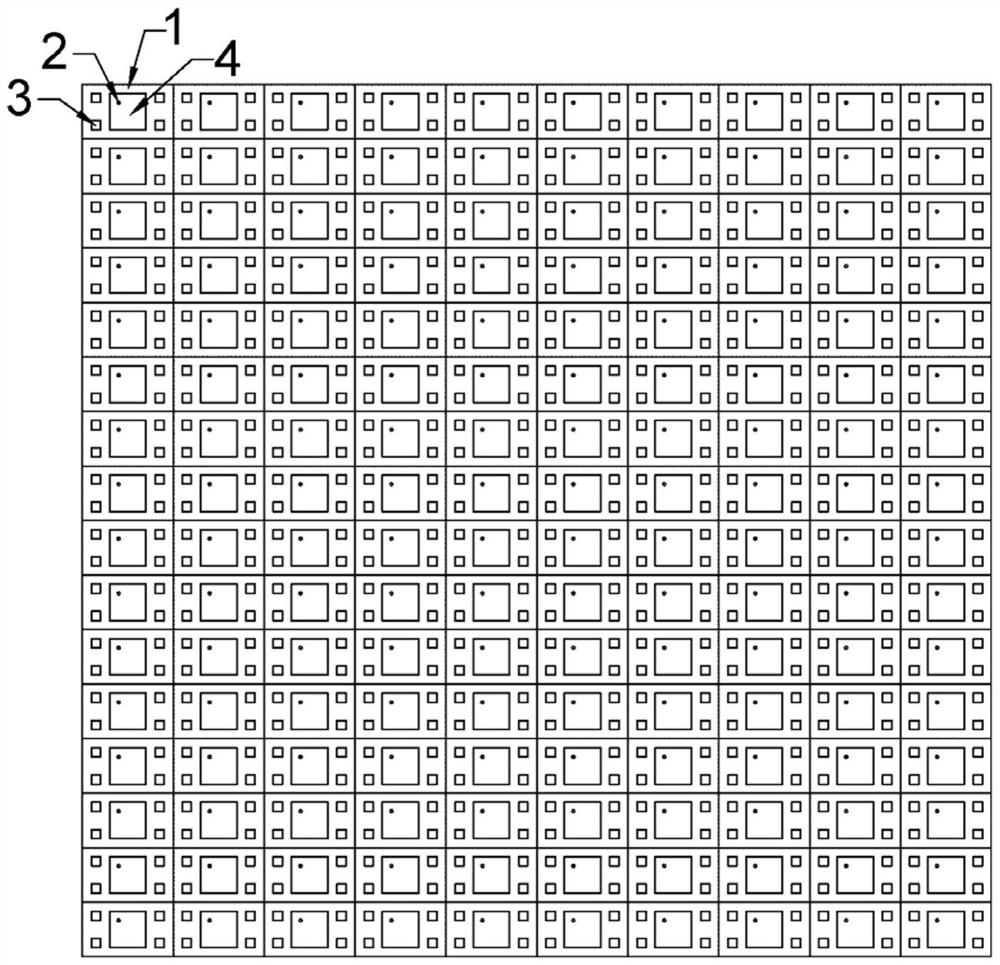

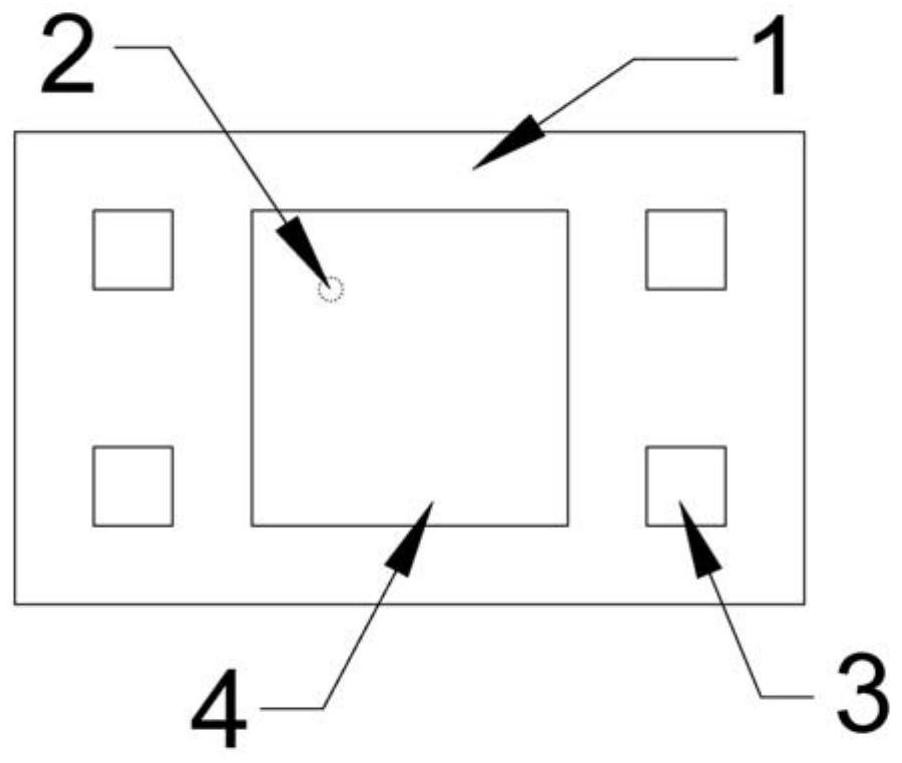

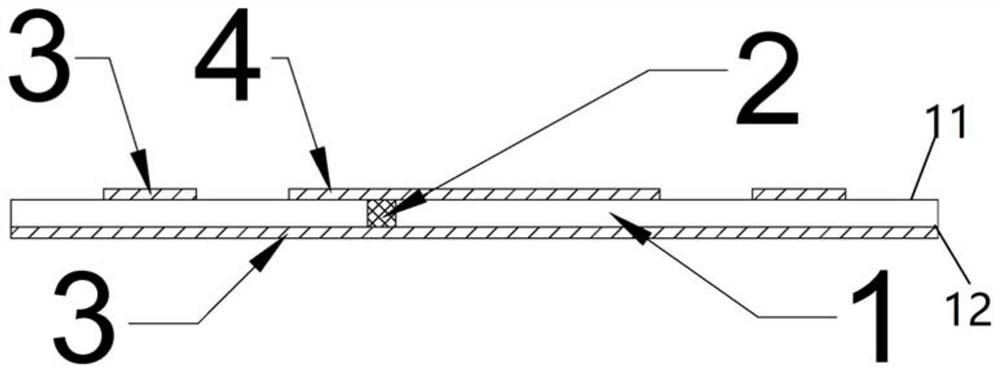

[0060] see figure 1 , in this embodiment, the aluminum nitride ceramic substrate 1 (aluminum nitride ceramic substrate with a thermal conductivity ≥ 170 W / m·K and a purity of not less than 95%) has a thickness of 0.25 mm, and both length and width are 51 mm. On the aluminum nitride ceramic substrate 1, 16 rows and 10 columns of 160 single-chip substrate designs are arrayed in a square area with a size of 50mm×50mm. The size of the designed ceramic chip substrate is 5mm×3mm. The design graphics are as follows: figure 2 and image 3 shown.

[0061] according to figure 1 In the array arrangement pattern shown, 160 light-transmitting through holes with a diameter of 0.08 mm are produced on the aluminum nitride ceramic substrate 1 by means of laser drilling.

[0062] Next, after the gold powder paste is filled in the light-transmitting through-holes by screen printing, the aluminum nitride ceramic substrate 1 is sintered at 850° C. for 5 minutes, so that the gold powder paste i...

Embodiment 2

[0067] First, if Figure 5 As shown, in this embodiment, the aluminum nitride ceramic substrate 1 (thermal conductivity ≥ 170W / m·K, purity not less than 95%) has a thickness of 0.38mm, a length and a width of 101.6mm, and its size is 100mm A total of 100 ceramic chip substrate design patterns are arranged in an array of 10 rows and 10 columns in a square area of ×100mm. The size of each small-sized ceramic chip substrate is 10mm×10mm, and its design graphics are as follows Figure 5 , Figure 6 , Figure 7 shown.

[0068] according to Figure 5 In the array arrangement pattern shown, 1700 light-transmitting through holes with a diameter of 0.1 mm are produced on the aluminum nitride ceramic substrate 1 by means of laser drilling.

[0069] Next, fill the gold powder paste in the light-transmitting through hole by screen printing, and sinter at 850° C. for 5 minutes. The gold powder paste in the through hole of the aluminum nitride ceramic substrate 1 forms 1700 gold cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com